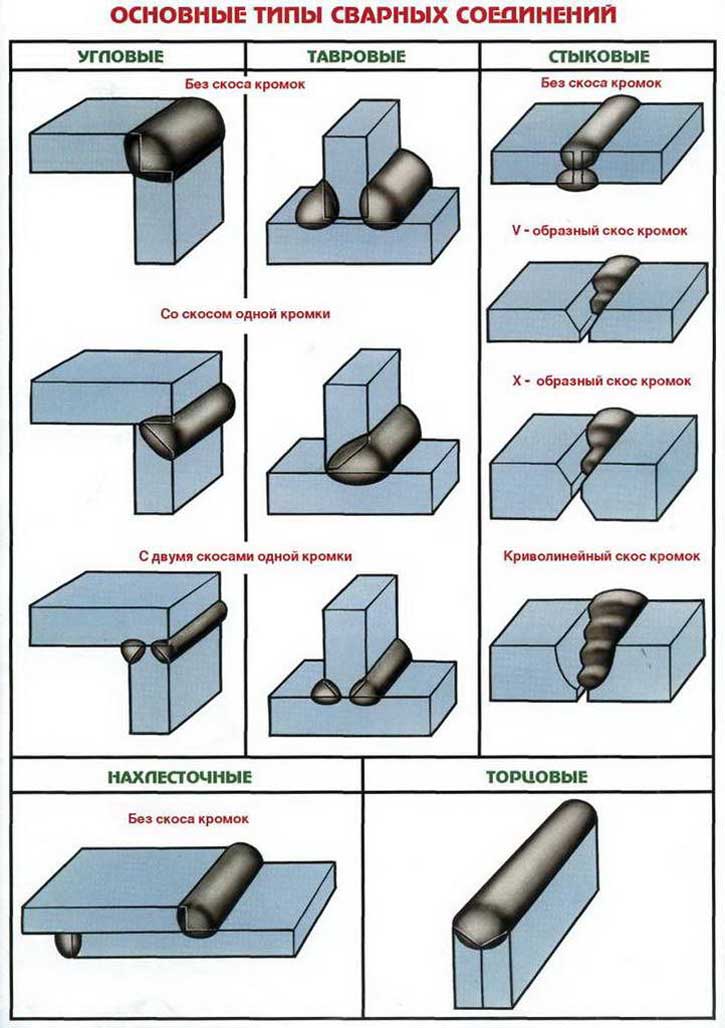

The quality of the welded connection directly depends on the type of seam seam, the electrode and the operation mode of the device. To do this, it is recommended to be guided by the current standards, and in particular - GOST 5264-80. It describes in detail the characteristics and types welded connections and types of welded seams. According to GOST, special requirements for the performance of work are imposed.

Shocks

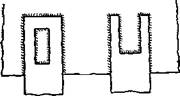

The most popular type of compound, as it is characterized by minimal metal voltage, ease of performance and reliability. Depending on the thickness of the welded edge, it can be trimmed at a direct or oblique angle. Also allowing the use of one-sided bevel.

Advantages of butt welding seams:

- minimum indicator of the consumption of the main and welding metal;

- optimal welding time;

- Good quality compounds.

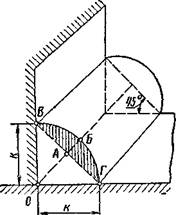

The latter is achieved only under the adherence to technology. The angle of the bevel can vary from 45 ° to 60 °. It depends on the thickness of the metal. Such geometry is used for sheets from 20 mm and more. The characteristics of the material are also taken into account.

Towls

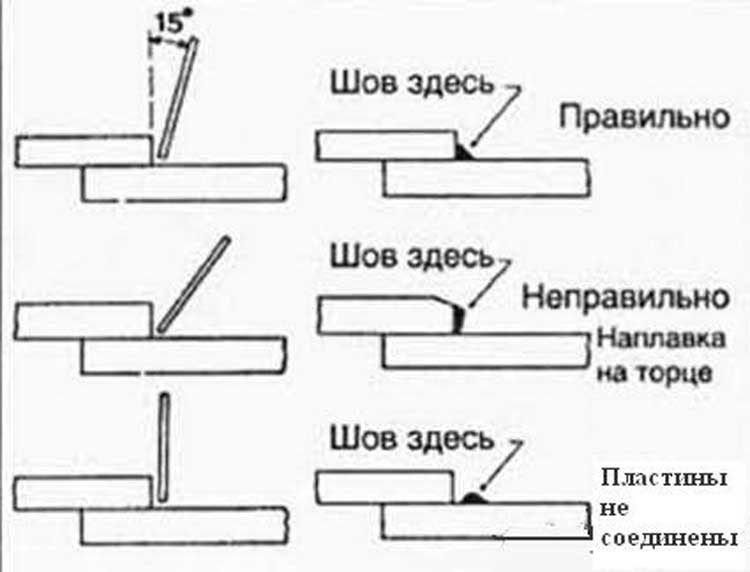

The formation of a compound by overlaying sheets to each other is relevant for the thickness of the metal in the range from 8-12 mm. At the same time, in contrast to the butt welding, there is no need to process the surface - it is enough to cut a blank. It is important to correctly calculate the magnitude of the adolescence.

Features of the fifth welded joint:

- increased consumption of the main and weld material;

- seam is formed between the surface of one sheet and the end of another;

- Scope - point, roller and contact welding.

Before starting work, sheets need to be aligned to ensure a dense clamp.

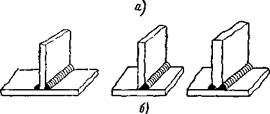

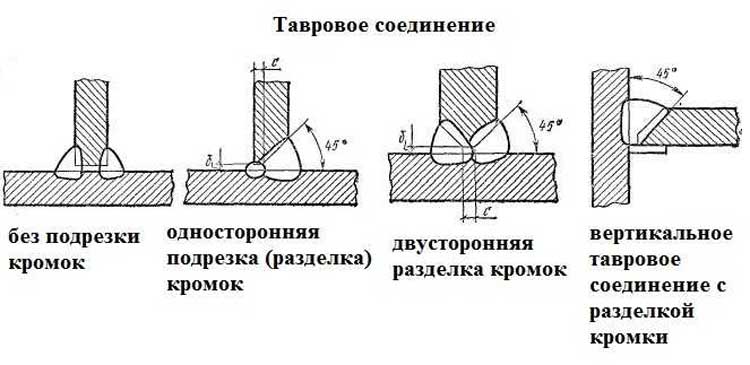

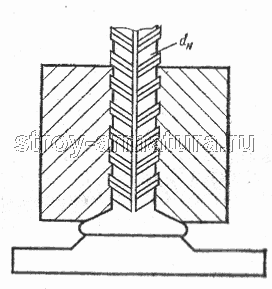

Taving

This is a T-shaped joint in which the end of one of the sheets is welded to the plane of the other. For reliability, one or two-sided squeaks can be made on the first. With their help, the volume of the weld metal increases. Scope - metal structures of complex form.

Before starting work, you must take into account the following factors:

The configuration of the bevels is standard, the angle depends on the thickness of the metal.

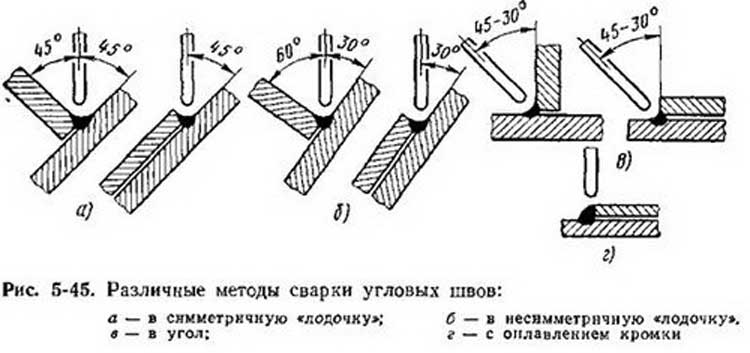

Corner

Used to connect two structural elements at a certain angle. In contrast to the brand compound, the presence of a gap is unacceptable. Reliability is ensured by the help of moles and large volume of directional metal.

Specificity of angular welds:

- Preparation of the surface is needed - the formation of the messengers of a simple or complex configuration;

- For thin-walled blanks, one-sided connection is allowed;

- Geometry is taken into account welded seam.

Such a method is most often used for the manufacture of tanks or similar to them in the form of the structure.

Auxiliary welds

In addition to the above-mentioned methods of connecting steel elements in GOST provided auxiliary. They can be used to form a reliable seam, taking into account the required performance of the product.

Depending on the specifics of the seam, the following techniques for the formation of a welded joint are used:

- Promotional. Need to achieve maximum reliability indicator. In one of the materials make a recess to install another sheet.

- Torch. Refer to the category side. Sheets are superimposed on each other, the seams are made on the ends of the design.

- With overlays. Recommended for structures with a complex surface configuration. A special pad that provides a connection of two components is applied.

- With electric plates. The process of compound formation is similar to the traditional rugging. The difference lies in the fact that the hole is filled with the weld metal.

The choice of one or another weld depends on the final result - the reliability and durability of the connection.

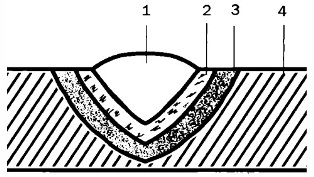

Weld seams are inhomogeneous in their structure and include the following zones: the zone of the main metal, weld, fusion and thermal influence.

Distinguish the following types of welding connections:

1) butt.

This is the most common type of compounds for various welding methods, which has some number of advantages, compared with others: high welding performance, minimizing the consumption of the welded and weld metal, high strength with proper welding technology, the absence of own structural stresses. In this case, such compounds require careful preparation of the edges and the accuracy of the interconnection of the edges of the parts when assembling for welding.

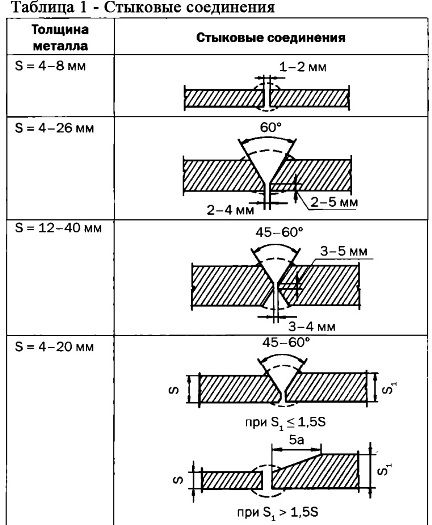

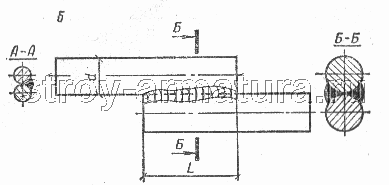

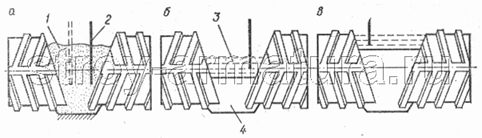

The edge cutting can be different, its examples are shown in Table 1.

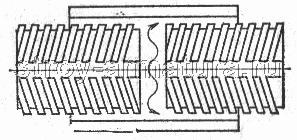

With a large edge thickness, a cup-shaped cutter is used, for a thickness of 20 ... 50 mm - one-sided, over 50 mm - double-sided. Button compounds are widely used when welding sheets, pipes, varietal metal.

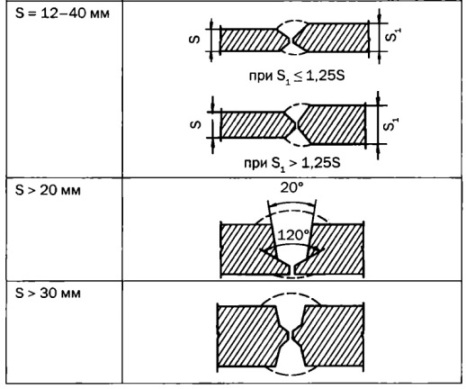

Fig. 1. Zones of welded compound: 1 - welded seam, 2 - zone of fusion, 3 - heat influence zone, 4 - basic metal zone

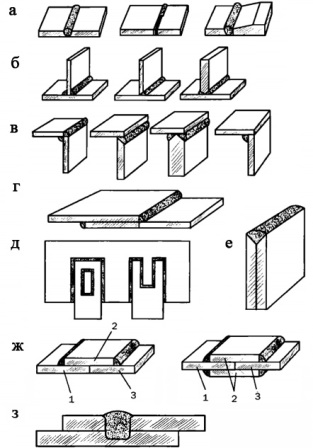

Fig. 2. Types of welded compounds: A - butt, b - brazier, in - corner, g - fettic, d - slotted, w - with overlays, z - with electric stakes, 1 ... 3 - main metal, 2 - pad, 3 - Elektrokel

2) corner.

Examples of angular compounds are shown in Fig. 2, c. They can be one-sided or bilateral to increase strength. Also used when welding sheet, shaped and pipe blanks. The angle of inclination of the blanks may be different, a pre-cutting edge is required.

3) Taving.

The vertical element of the taving compound should have a edge edge. SCOS is recommended to do on both sides, if the provision is not possible - only on the one hand. It should be ensured by the gap between the vertical and horizontal part for boiling to the entire thickness of the sheet. The TAVR is used to connect sheet blanks.

4) Tasteners.

Such compounds are mainly used in point and contact welding, since, in other cases, the consumption of the main and electrode metal is unreasonably increase. In the case of an outstanding connection, the cutting edges at an angle is not required, but they must be edged. To eliminate corrosion between sheets, it is recommended to persuade the connection on both sides.

5) end.

In this embodiment, the sheets are superimposed on each other in the form of "sandwich" and weld in common ends.

6) PRODUCT.

They are used when it is necessary to strengthen the fifth joint. The slot make in an open or closed version.

7) with overlays.

Such compounds are also used as an option for amplifying butt or threaded compounds. An example can be the use of strengthening rings on the inner surface when assembling-welding of tank shells.

8) with electric flames.

1. Steel welding technology

Preparation of designs for welding

Preparation of designs for welding is divided into three stages:

1. Processing of edges to be welding;

2. Assembling design elements for welding;

3. Additional cleaning, if required, collected under the welding of connections.

Processing the edges of the designs to be welded is made in accordance with the designs of structures and according to the requirements of GOST 5264-80 and other guests on the main types and structural elements of welded joints. The edges of the compounds for welding are treated on edging-ethnic or milling machines, as well as by oxygen and plasma cutting on special machines. The dimensions of the elements of the edges must comply with the requirements of GOST.

An important step in the preparation of the design to welding is the assembly for welding. Under manual arc welding of designs are collected using assembly devices or taps. The composition of assembly devices: clamps 1 perform a variety of surgery for assembling angle metal, beams, strips, etc.; Wedges 2 are used to build leaf structures; levers 3 - for assembling the angular metal and other structures; Corresponding corners 4 and corner locks 8 - for assembling sheet structures; Jacks 5 - for tightening the shells, beams and other structures; pads with wedges 7 - for assembling leaf structures with compliance with the size of the gap; Coupling strips 10 and squares. And - to build leaf structures for welding without taps. Apply other types of fixtures.

Before assembly, the processed elements of the structures should be measured, their edges are examined, as well as the metal adjacent to them, are thoroughly cleaned from rust, oil, paints, dirt, ice, snow, moisture and scale. In the workshop conditions, elements of structures are collected on racks - plates having a grooves for installing devices (bolts, screeds, pins, etc.), fastening collected elements in size provided in the drawings. The simplest racks from horizontal beams mounted on racks with a height of 200-400 mm are also used. At 13.3, an example of assembling leaf structures is shown using the simplest devices and assembly of structures from the profile metal - angular, altar, and the like. The edges of the collected designs to be welded in their form and sizes should correspond to the drawings and standards.

The joints of the structures as the assemblies are fixed by the patches - short welds to fix the mutual location of the parts to be welded. Tapes are placed in places location of welds, except for their intersection of the length of the length of the cracks for steels with the yield strength up to 390 MPa should be at least 50 mm and the distance between them - no more than 500 m, for steels with the yield strength of more than 390 MPa 100 mm long and the distance between them is not more than 400 mm with a small thickness of the parts collected (4-6 mm), the tapes can be shorter (20-30 mm) and the distance between them is 200-300 mm. When assembling on the patches of bulky heavy structures, cantible when welding, the arrangement of tapes and their value are indicated in the design of welding work. Keudal when welding tapes must be carried out by welders, which will subsequently weld the closed compounds.

The tapes give the stiffness of the structure and prevent the movement of parts from the shrinkage during welding, which can lead to the formation of cracks, especially in the elements of a large thickness. Therefore, the assembly on the patches is used with a thickness of metals 6-10 mm, and with a greater thickness, assembly fixtures are used, fixing the shape and dimensions of structures, but allowing it a slight movement from the welding shrinkage. Such devices are wedge screeds (see 13.1).

Immediately before welding, the collected joints are subject to mandatory inspection and, if necessary, to further correct the defects of assembly and cleaning.

When welding in a vertical position, the current is reduced by 10-20%, when welding horizontal seams - by 15-20% and with welding ceiling seams - by 20-25%.

Current and polarity are determined depending on the electrodes adopted for welding, for example, an alternating or permanent current can be applied to the electrodes of MR-3, for UONY-13/45 electrodes - only permanent current reverse polarity etc.

The speed of welding (arc movement) largely depends on the qualification of the welder and the ability to conduct the process of welding with interruptions only to change the electrode. In addition, the coefficient of the applied electrodes and the power of the welding current affect the welding speed. The greater the surfacing coefficient and the strength of the current, the faster the arc moves and, therefore, the speed of welding is growing. It should be borne in mind that an arbitrary increase in current may cause an electrode overheating.

The coefficient / s, determined by table. 13.1 depends on the type of electrode coating. For example, for electrodes with an acidic or rutile coating, the maximum value of the coefficient at a diameter of 3-4 mm K \u003d 45; for electrodes with the main coating with a diameter of 3-4 mm d "\u003d 40; with cellulose coating of the same diameter / (\u003d 30.

Based on the formula of the power of welding QN (ch. 3), an approximate dependence of the power energy from the cross section of the seam roller, J / mm

where Qo is a coefficient depending on the type of electrodes used or wires with mechanized welding methods; FM-\u003e Roller cross section area, mm2.

For electrodes of the brands of Uoni-13/45 and CM-11, the quantity QO \u003d 65 J / MM3. Thus, knowing the robust energy, you can easily determine the cross section of the roller of the seam and vice versa.

2. Types of welded connections. Welds

Terms and definitions of basic concepts for metal welding establishes GOST 2601-84. Welded connections are divided into several types defined by the mutual location of the welded parts. The main ones are butt, angular, brazers, fatty and end connections. To form these compounds and ensure the required quality, the edges of the structures connected by welding must be prepared in advance. Forms of preparation of edges for manual arc welding of steel and alloys on the ironoponecel and nickel basis, GOST 5264-80 is installed.

Junction Call the connection of two elements adjacent to each other end surfaces.

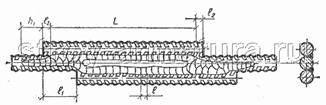

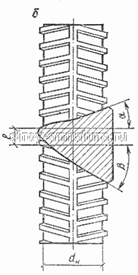

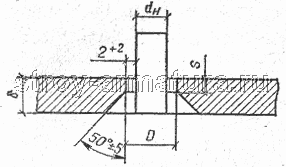

GOST 5264-80 Provided 32 types button connections, conventionally designated Cl, C2, C28, etc., having different edges preparation, depending on the thickness, the location of the welded elements, welding technologies and the presence of equipment for processing edges. With a large metal thickness, manual welding it is impossible to ensure the carriage of the edges to the entire thickness, so they make the cutting edge, i.e. Scope of them from two or one hand. The edges are mounted on a planer machine or thermal sharp (plasma, gas oxygen). The overall corner of the bevel (50 ± 4) °, such a preparation is called one-sided with a twist of two edges. At the same time, the magnitude of the dullness (incomplete part) and the gap, the values \u200b\u200bof which are set by the standard, depending on the thickness of the metal should be supplied. The seam of the butt compound is called the joint seam, and the welding seam is a smaller part of the two-sided seam, which is previously performed to prevent burns during the welding of the main seam or overlap, after its execution.

When preparing edges, 8-120 mm thick became thick. Both edges of the welded elements are mounted on both sides to an angle (25 ± 2) ° each, while the total bevel angle is (50 ± 4) °, dulling and the gap are set by the standard depending on the thickness of the steel. Such preparation is called two-sided with a twist of two edges. In this preparation, the processing of edges is complicated, the volume of the weld metal decreases sharply compared with one-sided preparation. The standard provides several options for two-way edges: preparation of only one upper edge used in the vertical location of parts, preparation with uneven PS with the thickness of the edges, etc.

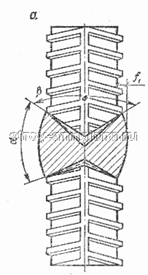

Angular compound Call the connection of two elements at an angle and cooked in the place of adjoining their edges. Such compounds are 10: from U1 to U10.

For a thickness of a metal 3 - 60 mm, the edge of the adjoining element is mounted at an angle (45 ± 2) 1 °, the welded seam of the main and under-boat. At the same thickness and end-to-end province you can do without a welding seam. A corner connection with a steel lining is often used, which provides a reliable provider of elements throughout the cross section. With a metal thickness, 8-100 mm use a two-sided cutting of the adjacent element at an angle (45 ± 2) °.

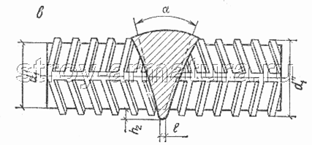

Taurus compound They call a welded joint in which the end of one element adjoins at an angle and welded the corner seams to the side surface of another element. The standard provides several types of such compounds: with T1 on T9. A compound is a compound for a metal with a thickness of 2-40 mm. For such a compound, no bevel edges are made, but provide a smooth trimming of the adjacent element and the smooth surface of another element.

With a metal thickness of 3-60 mm and the need for a continuous seam between the elements, which is provided for the design of the structure, in the adjacent element make the edge cutting at an angle (45 ± 2) °. In practice, a brand compound with a lining was often used with a thickness of steel 8-30 mm, as well as a compound with two-sided bevel edges of the adjoining element with a thickness of steel 8-40 mm. All of these compounds with the bevel edges of the adjacent element provide a solid seam and the best working conditions of the structures.

Nethreading compound Call a welded joint in which elements welded with angular seams are parallel and partially overlap each other. The standard provides two such compounds: Hi and H2. Sometimes the varieties of the threader compound are used: with a lining and with point seams connecting parts of the design elements.

From the listed welds, the most reliable and economical are butt compounds in which existing loads And efforts are perceived in the same way as in whole elements that have not been welding, i.e. They are practically equivalent to the main metal, of course, with the corresponding quality of welding. However, it should be borne in mind that the processing of the edges of the butt compounds and their adjustment for welding is quite complex, in addition, their use is limited to the features of the form of structures. Corner and taving compounds are also common in constructions. Towling compounds are the most simple in work, as they do not need a preliminary cutting of edges, and preparations for welding are easier than butt and angular compounds. As a result, as well as due to the structural form of some structures, they obtained the propagation to connect the elements of a small thickness, but allowed for elements with a thickness of up to 60 mm. The disadvantage of petitioner compounds is their uneconomicity caused by the overruns of the main and weld metal. In addition, due to the offset of the line of action during the transition from one part to another and the occurrence of stress concentration, the carrying capacity of such compounds is reduced.

In addition to the listed welded joints and seams, with manual arc welding, connections are used under sharp and stupid angles according to GOST 11534-75, but they are much less common. For welding in protective gas, welding of aluminum, copper, other non-ferrous metals and their alloys, welded joints and seams provided by separate standards are used. For example, the form of the preparation of edges and seams of pipelines is provided for by GOST 16037-80, in which the main sizes of the seams for various types of welding are determined.

3. Welding of reinforcement of various classes

Currently, in construction, the large amount of welding work is to weld the reinforced concrete reinforcement. Welding is used in the manufacture of welded reinforcement products, mortgage parts and installation of precast concrete structures (Table 2).

table 2

| Welding method and its characteristics | Purpose | Position rods when welding | View of welding |

|

under the flux without an additive metal, automatic and semi-automatic |

Production of mortgage parts: Thorn rods with flat elements | Static and dynamic | |

| Taurus connection of rods with flat elements | Vertical | ||

| Bathroom under flux in inventory forms, semi-automatic | Butt compounds of output of single rods of reinforcement in places of conjugation of fittings of products and precast concrete structures | Horizontal vertical | Static, dynamic and repeated repeated |

| A single-electro bathroom in inventory forms with a smooth inner surface, manual | Horizontal | ||

| Single-hectric bathroom with steel groove lining, manual | Horizontal | ||

| One-Elektrome Bathtub-Suture With Steel Groove Lining, Manual Open Arc Naked Alloy Wired, Multilayer Seams with Steel Grooves Lining, Semi-Automatic | Horizontal vertical | ||

| Single-electrode multi-layer seams with steel grain lining or without it, manual | Vertical | Static and dynamic | |

| Extended seams | Horizontal | ||

| Bathroom Multielectrode in inventory forms with recess for the formation of enhancement seam | Horizontal | Static, dynamic and repeated repeated Static and dynamic |

The main types of welding during installation of reinforcement products and precast concrete structures are manual arc and semi-automatic welding with coated electrodes or welding wire, respectively. For reinforced concrete structures, hot-rolled steel according to GOST 5781-75 *, a round, smooth and periodic profile, which, depending on the mechanical properties, is divided into 5 classes: A-I, A-II, A-III, A-IV, A- V (Table 3).

Table 3.

| Armature class | Welding methods | |

| stretched seams | multilayer seams, Bathroom Multielectrode, Bathroom One-Elector | |

| A-I. | E42A-F - WONI 13/45, CM-11, UP2 / 45, E42-T - ANO-5, ANO-6, ANO-1, E46-T - ANO-3, ANO-4, MR-1.MR -3, OZSC-3, OZSC-4, OZSC-6, VIS-2 | E42A-F - WONI 13/45, CI-11, UP-2/45 |

| A-II. | E42A-F - WONI 13/45, CM-11.UP 2/45, OZSC-2, E42T - ANO-5, ANO-6, ANO-1, E46T-ANO-3, ANO-4, MP-1, MR-3, OGSC-3, OZSC-4, OZS-6, VIS-2 | E42A-F - Woni 13/45, CM-11, UP2 / 45, OGSC-2, E50A-F - Woni 13/55, DSK-50, UE 2/55, K-5A, E55-F - Woni 13 / 55u |

| A-III. | E42A-F - WONI 13/45, CM-11, UE2 / 45, OGSC-2 E50A-F - Woni 13/55, DSC-50, UE 2/55, K-5A E55-F - WONS 13 / 55U | E50A-F - WONI 13/55, DSC-50, UE 2/55, K-5A, E55-F - WONS 13 / 55U |

Notes:

1. The brands of welding wire are indicated in the order preferably to use.

2. The diameter of the welding wire of a solid section 2-2.5 mm, powder wire - 2-3 mm.

3. An asterisk was marked with a welding wire brand, used only when welding of class A-II grade 2GT fittings.

Class A-1 reinforcement rods must be released round smooth; Rod classes a-iI, A-III, A-IV and A-V periodic Profile. Each class of reinforcement steel must correspond to GOST 5781-75 *.

4. Technological features that need to be considered when welding fittings and mortgage parts

Welding rods of reinforcement reinforcement in the installation conditions

In reinforced concrete structures, the connection of reinforcement rods is carried out, as a rule, one of the electric arc welding methods or semi-automatic, namely:

- without steel brackets;

- on steel brackets;

- with round lining or overlap;

- in inventory forms (copper or graphite);

- Vangest or Putavr with flat elements.

Before assembling the assemblies of the rods of reinforcement, it is necessary to make sure that the steel, sizes and the mutual arrangement of the combined elements of the project and the correspondences of GOST 10922-92 the collected joints for welding.

Editions of rods, mortgage products and connecting parts must be cleaned to a pure metal in both directions from edges or cutting 20 mm from dirt, rust and other contaminants. Water, including condensation, snow or ice, should be removed from the surface of the rods of reinforcement, mortgage parts and connecting parts by heating them with a flame of gas burners or soldering lamps to a temperature not higher than 100 ° C.

With enlarged, compared to the required, gaps between the jacket rods, the use of one insert is allowed to be used, which should be made of fittings of the same class and diameter as joined rods. When welding rods with overlays, the increase in the gap should be compensated by an appropriate increase in the length of the linings.

The length of each release of reinforcement from the body of concrete should be at least 150 mm at normal gaps between the ends of the rods and 100 mm - when using inserts. It should be striving to produce products so that the length of the releases allow the installation and welding without inserts, i.e. Conditioning the gap between the releases to produce at the installation site using gas cutting.

Precast concrete structures mounted only on issues should be collected in conductors providing a design position. Welding rods of reinforced concrete structures held by the crane is not allowed.

Precast concrete structures that have mortgage parts should be collected on patches. The tapes must be placed in the places of the subsequent imposition of welds. The length of the tape should be 15-20 mm, and the height (catat) is 4-6 mm. The number of tapes should be at least two. Practice should be performed using the same materials and the same quality as the materials for the main seams. Before welding the main seams, the surface of the tape and adjacent sections should be cleaned from slag and splashes of metal. Tapes must perform trained welders who have certified for the right to produce these works.

It is not allowed to have burns and swelling from arc welding on the surface of working rods. Burns should be cleaned with an abrasive circle to a depth of at least 0.5 mm. At the same time, a decrease in the cross-sectional area of \u200b\u200bthe rod (recesses in the main metal) should not exceed 3%. The place of mechanical stripping should have smooth transitions to the body of the rod, and the risks from abrasive processing should be directed along the rod. Cutting ends of the electrical arc rods when assembling structures or cutting edges of the rods is not allowed. These operations should be performed by special electrodes for cutting reinforcement of the brand of the OZR-2.

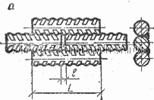

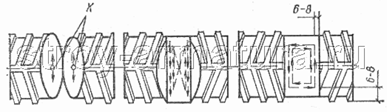

Manual armature armature welding extended seams

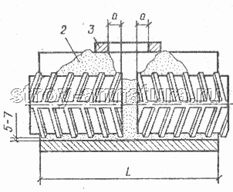

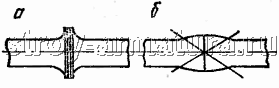

Manual armature armature welding is used to dock vertical and horizontal rods. The welded connection may be peeling and with overlays. The fattest compound is carried out, as a rule, extended seams, but arc points can be applied. In addition, it is possible to connect reinforcement rods with a long and short backyard, as well as with one-sided or double-sided seam (Fig. 1).

Fig. 1. Faucetic welded reinforcement of reinforcement with long sewage - with a long filament in one-sided seam; b - with short faint and double-sided seams

Welded reinforcement rods with overlays, round or corner can be long and short. In this case, the lining can be shifted in length. Armatic arc welding is performed by flanking seams: two one-sided, two double-sided, four bilateral, one-sided with "mustache" (Fig. 2). When welding fittings with double-sided seams when applying a second seam from the reverse side of the connection, longitudinal hot cracks may occur in it. To prevent the occurrence of such a type of cracks, careful selection of the type of electrodes and strict maintenance of the technological mode of arc welding is necessary. Depending on the diameter of the jammed rods, extended welds may be single-pass and multipliers. The current for arc welding is chosen depending on the type of electrodes. At the same time, with arc welding of reinforcement in a vertical position, the current should be 10-20% less than for horizontal rods.

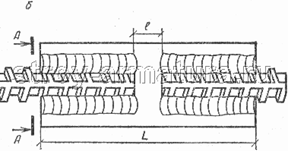

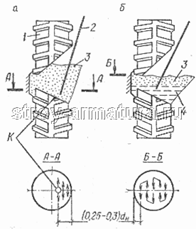

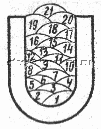

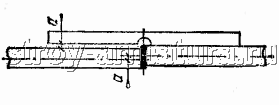

Manual armature armature welding multi-layer seams without additional technological elements

With minor work and availability of highly qualified welders, armature armature armature is possible with multi-layer seams without molding elements. In this way, it is recommended to provide arc welding of reinforcement compounds in the vertical position of the following classes of reinforcement steel: A-1 (Ø 20 - 40 mm), A-2 (Ø 20-80 mm), A-3 (Ø 20-40 mm). The structural forms of the ends of the reinforcement rods during their dock are shown in Fig. 3. Forms of cutting, corners of the bevels and their direction, dull and their size, gaps between the ends of the rods are standardized.

Fig. 3. Button welded reinforcement compounds performed without additional elements

and - vertical single-row coaxial rods with free access from two sides to the welding location; B - when the connection is available on the one hand; B-horizontal coaxial rods with cutting ends

Armatic arc welding is performed by a single electrode. The welds are superimposed first on one side of the cut, then on the other to its entire width. In the process of separating the cutting, the filtered metal is periodically cleaned of slag. The arc electrical welding mode is set in accordance with the passport data of the electrodes. Usually for this type of electric welding use electrodes with fluorinistocalcium coating type E55 or E50A.

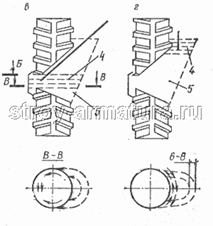

Manual armature armature welding with compulsory seam formation

In some cases, the project requires welded joints of crusades of reinforcement with forced seam formation. For such reinforcement products, it is recommended to use rods with a diameter of 14-40 mm from steel of classes A-1, A-2, A-3. Pre-rods are collected in conduitors that provide their tight adjuncing to each other, or fixing the rods reach using welding tapes. In this case, conductors and tapes should not prevent the installation of molding elements.

Manual arc point welding by patches of two rods

In the conditions of the construction site, during the construction of monolithic reinforced concrete structures of buildings and engineering structures, grids and frameworks manufactured in place are widely used as reinforcement products. In such products there are many different crosses, which are welded using manual arc welding points.

The limited use of most grades of steel grades A-2 and A-3 are caused by the fact that during point welding in the contact of the cross compound rods is quickly allotted from the weld metal, which leads to a local hardening of steel, and therefore, to an increase in its fragility. Especially sensitive to the specified thermal effects of medium carbon and low carbon reinforcement steel.

Bathroom semi-automatic welding of reinforcement under flux

Welding of reinforcement with the use of a bathroom of semi-automatic welding of horizontal reinforcing rods is performed using additional technological elements: detachable forms or removable linings (steel, copper, graphite). The most favorable conditions for crystallization of the seam metal are created in copper and graphite molding devices, which allows you to get a metal weld metal with high indicators of mechanical properties.

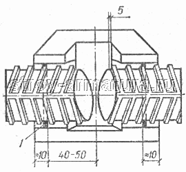

The molding devices are set symmetrically the gap between the ends of the attached rods of the reinforcement (Fig. 4). At a distance of 40-50 mm from the vertical axis of the joint on the rods, 2-3 cords of the cord asbestos are imposed for a dense adjoining of the reinforcement to the shape. Then 20-30 g. Flus fall into the melting space. If copper forms are used, then before their installation, the flux is poured onto the bottom of the layer of 5-7 mm. Such a measure allows the weld in the lower part of the joint.

Fig. 4. Installation of detachable forms and copper lining on the welded rods when welding fittings

1 - Chupmer Asbestos; 2 - flux; 3 - centering frame - pointer of melting boundaries

Excite welding arc, touching the end of the wire of the lower edge of the end of the reinforcement rod. The flow of the lower part of the end of the rod occurs at the oscillatory movements of the wire across the axis of the rods for 5-15 s. Then the similar transaction operation is performed with the second rod. The movement of the end of the electrode wire during the welding of the valve when filling the bath with a liquid metal is shown in Fig. 5. When welding the reinforcement with a diameter of 45 mm and more can be used a additive in the form of a metal grunt, sawdust, chopped wire in an amount of 25-35% of the metal weld metal. To maintain the optimal depth of the slag bath (15-20 mm), flux is added periodically portions.

Fig. 5. Schemes for moving the end of the electrode wire (shown by arrows) with a semi-automatic bathroom welding of horizontal reinforcement rods (the form is conditionally not designated)

a - in the initial period of the propellation of the lower edges of the ends of the rods (k - the point of touching the electrode wire of the ends of the rods to excite the arc); b - in the process of filling the cutting of the rods; in the final stage 1 - flux; 2 - electrode wire; 3 - slag bath; 4 - metal seam.

Arc welding of butt connections of vertical rods under flux, as a rule, are performed in removable copper or graphite forms. After the arc is excited, the end of the electrode wire is moved by oscillatory movements according to the scheme shown in Fig. 6. After the end of the end of the lower rod, in order to avoid the underriment of the upper rod in the process of electrical welding, adjust the voltage, removing it with steps by 15-25% (2-4 times). The mode of bathroom arc welding of the butt compounds of vertical rods is similar to the welding of horizontal reinforcement rods.

Fig. 6. Schemes for moving the end of the electrode wire with a semi-automatic bathroom welding of rods with a knocker bevel of the lower rod to the welder (the form is conditionally not designated)

a - in the initial period of penetration of the lower part of the end of the lower rod; b - in the process of regulation of the middle part of the end of the lower rod; in the same, cut end of the top rod and sewage cutting rods; G - at the final stage

1 - reinforcement rod; 2 - electrode wire; 3 - flux; 4 - slag bath; 5 - metal seam.

Semi-automatic welding of reinforcement open arc naked wire (sododp) on steel bracket-pad

Semi-automatic welding of reinforcement reinforcement naked wire (SODOP) is used for welding compounds of vertical and horizontal rods when installing the monolithic reinforced concrete structures and in assembly conditions. This welding of reinforcement is multi-layered and produced using a doped welding wire with a diameter of 1.6 and 2 mm brands of SV-20GSTU and SV-15GSTU. The assembly of the butt compounds of the reinforcement rods leads on the remaining steel grain lining. These linings are attached to the reinforcement rods with two patches.

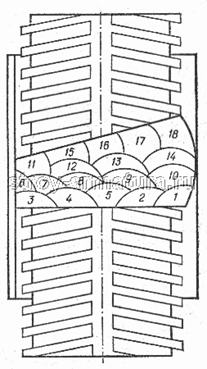

Fig. 7. Technique of surfacing of multilayer seams under arc welding of reinforcement open arc naked wire horizontal rod compounds (the numbers indicate the order of surfacing of the layers)

When welding horizontal reinforcement rods, a doping wire with a diameter of 2 mm is used. The sequence and scheme of moving the wire when filling the cutting is shown in Fig. 7.

In the process of the clamping of the cutting is possible overheating of the reinforcement rods. In order to avoid this, it is recommended to conduct consistent armature welding of two or three compounds. In this case, the cutting of the first joint is plugged by 60-70% of its volume after which they go to the second joint, and then on the third one. Filling into a metal-powered third joint by 60-70% of the volume turns into the first joint, fill all its melting space by the weld metal and the remaining joints are brewed in the same sequence. The electrical welding of the joint is completed by surfacing two flanking seams with a cathet 8-12 mm. The joints of the vertical rods of reinforcement are welded as well as horizontal. After the faving of the butt space, the flank seams are applied in the direction from top to bottom. The sequence of the weld overlay is shown in Fig. eight.

Fig. 8. Technique surfacing multi-layer seams when welding the reinforcement of open arc naked wire vertical connections of rods (numbers indicate the order of surfacing layers)

At the specified methods for welding the reinforcement open arc naked wire (SIDP) for horizontal and vertical rods, the following classes of reinforcement steels are recommended (in brackets are the diameter of the rods in mm): A-1 (20-40), A-2 (20 - 80), A-3 (20-40), AT-3C (20-22), AT-4C (20-28). The ratio of the diameters of the reinforcement rods (smaller to more) should be within 0.5-1.0. Steel AT-3C and AT-4C should be welded on an elongated up to 4D lining.

Wire for mechanized arc welding of reinforcement

With mechanized welding under flux, in protective gases and without additional protection, self-protecting wire and for welding with the forced formation of the seam, the electrode wire of the solid cross section and tubular (powder), which is a steel round cross-section filled with powder. For welding carbon and low-alloy structural steels in protective gases, the following brands of electrode wire are used: SV-08GS, SV-12GS, SV-08G2C, SV-08GSMT. For welding with multilayer seams without additional protection of low-carbon, medium carbon and low-alloy steels, a doped electrode wire of stamps of the ST-15GSTU and SV-20GSTU is used.

Powder wire is used both for welding and for surfacing. For the manufacture of powder wires apply a ribbon from low carbon steel grade 08CP cold rolled products. Currently, the industry produces five types of powder wire (Fig. 9) with a diameter of 1.2-3.6 mm.

Powder Wire of a simple cross section with one longitudinal slit Powder wire of a simple section with two longitudinal slots of a complex cross section with one melted end of the steel tape Powder coating wire with two melted ends of the steel tape Powder wire tube without longitudinal slotFigure 9. Section of powder wires of different types.

For arc welding of low-carbon, low-alloyed and middle-deregular steel, depending on the welding method, various types and brands of powder wire are used: self-protecting wires of general purpose brands of PP-AN1, PP-AN7, PP-2DSK; Wire of general purpose for welding in carbon dioxide Gas brands PP-AN8, PP-An21; self-defense wire for welding with coercive seam formation, for example, PP-An15 brands, PP-An19n, PP-2VDSK; Wires for welding in carbon dioxide with the forced formation of seam of brands of PP-An5 and PP-ARSS.

Contact torque welding of reinforcement

The main type of reinforced concrete structures are intersecting rods in the form of grids and flat frames. For welding of the reinforcement structures, as well as for welding a ring of round reinforcement rods to flat rolled elements (strip, corner and other varietal steel) apply contact point welding.

Contact point welding gives a number of advantages compared to other types of welding: the possibility of increasing labor productivity due to lower labor intensity in the manufacture of reinforcement frames and grids compared to electric arc welding; small electricity consumption due to the use of hard welding modes using high density current over a very small time segment; the possibility of mechanization and automation of the process; Lack of metal consumption (in electrodes).

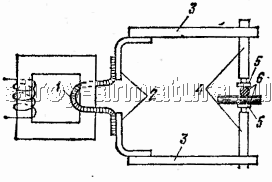

Figure 10. Contact point welding of reinforcement

Current flow circuit with contact point electric welding: 1 - secondary turret of the transformer; 2 - copper tires; 3 - trunk; 4 - electrode holder; 5 - electrode; 6 - reinforcement rod

The essence of the process of contact point welding of reinforcement is as follows. From the secondary turn of the welding transformer through copper tires, trunks, electrode holders and the electrodes of the current are summarized to the intersection of reinforcement rods sandwiched between the electrodes (Fig. 10). Electrodes have water cooling. The resistance in the place of contact of the reinforcement rods is many times the resistance of the rest of the chain, so it is precisely in this place that heats up heat that heats the metal of reinforcement rods to the plastic state. Under the action of the force of compression of the electrodes, their welding occurs.

To obtain weld connections of the required strength, it is necessary to weld on certain modes. The welding mode is chosen depending on the diameter of the welded reinforcement and steel grade, from which it is made. The correctness of the selection of welding mode is tested by the control test of the strength to the cut of welded valves.

If the strength of welded reinforcement compounds due to the undevelopment is less required, then the current density or the flow of it increases. If the strength is insufficient due to the face, the same indicators decrease accordingly.

With insufficient current density, the welding of reinforcement can be impossible even if the current flow rate is very long; With an excessive high density, reinforcement rods can overdo it.

The current density in the contact point welding machines is adjusted by switching steps of the welding transformer, and the duration of the current flow - move the pointer on electronic time controls.

For contact point welding, special machines are used, which, according to the number of simultaneously welded nodes of meshes and flat frames, are separated into single-point, two-point and multipoint.

Machines for spot welding are stationary and suspended; with one-sided and double-sided current; With a pneumatic and pneumohydraulic mechanism for compressing electrodes. Current flow control is automatically performed.

In connection with the development of construction from reinforced concrete in the direction of creating large reinforced concrete panels and other elements, there was a need to consolidate assembly of reinforcement frames and grids. For this purpose, mobile (suspended) welding machines are created, since on conventional welding machines, it is impossible to perform point welding of such reinforcement due to its cumbersome and large mass.

Suspended welding machines are separated by a constructive feature into two groups: with a built-in welding transformer and with remote. All machines are made according to the same scheme and consist of the following main nodes: housings with a handle, a welding transformer, a power pneumatic actuator, an electrode portion (ticks) and a suspension device that allows you to rotate the machine and ticks around its axis by 360 °.

Suspended machines with a remote transformer, in addition, supply with current-handed cables.

Weldability of reinforcement

Carbon steel weldability (GOST 380-71 *) is provided by the manufacturing technology and compliance with all requirements for the chemical composition, which are presented to steel B and B. Supply of steel groups B with a welding guarantee is negotiated in the order and in the certificate. Steel containing more than 0.22% carbon is used for welded structures under conditions that ensure the reliability of the welded joint. Steel Marks Es1, Eskin, the use of all categories and all decksens of deoxidation, including with an increased manganese content, and at the request of the customer, steel brands BST1, BST2, the second category of all decks, including with an increased manganese content, comes With a guarantee of weldability. The weldability of low-alloy reinforcement steel of all brands, except 80s, is also provided chemical composition and manufacturing technology. The welding of thermally hardened reinforcement steel is not allowed due to its softening in the weld zone.

Steel reinforcement thermally hardened welded has a "C" index. For example, the conditional designation of the welded reinforcement steel with a diameter of 14 mm AT-4: 14At-4C GOST 10884 - 81, and the welded steel with increased resistance to corrosion cracking under the tension is indicated by the "SC" index, AT-5C. According to GOST 10922-75, the time resistance of welded compounds of the AT class of the AT, made contact-butt, contact-point and sovne-butt welding, should not be less than the smallest value of the brave minimum,

Low carbon steel (carbon content up to 0.22%) refer to the category of welding well-weldable on weak modes without additional technological operations. Medium carbon steel (carbon content 0.23-0.45%) in the welding process requires such additional operations. Thus, to increase the resistance of the weld metal to the formation of crystallization cracks, the amount of carbon in it is reduced, applying welding electrodes with a reduced carbon content, as well as reducing the share of the main metal in the weld. Reducing the likelihood of the formation of hardening structures in the weld metal can be achieved using the preliminary and suitable heating of products.

Table 4. Preheating steels (before welding)

Table 5. Heat treatment steels after welding

Low-alloyed steel, containing less than 2.5% of alloying components and up to 0.22% of carbon, as a rule, have good weldability. Applied for the manufacture of reinforced concrete structures of low-carbon steel grades 18G2C, 25G2C, 25GS, 20HG2Cs refer to the category of satisfactorily weldable. These steel contain no more than 0.25% of carbon. If carbon is greater than 0.25%, quench structures and cracks can occur in the weld zone, as well as pore formation due to carbon burning. In tab. 4 shows the recommended heating modes of heat-treated steels before, and in Table. 5 after welding. It should be borne in mind that the recommended limit values \u200b\u200bof the criteria for the weldability of steels are inconsistent and may vary depending on the development of welding equipment and technology.

Contact shock welding of reinforcement

Contact butt welding is an effective method of connecting rods, since it does not require a metal of melting electrodes for its implementation; Provides high productivity, and also allows you to mechanize and automate the workflow.

The disadvantage of contact butt welding is the possibility of its use only in stationary conditions due to the considerable mass of welding equipment and a large consumption of electrical energy.

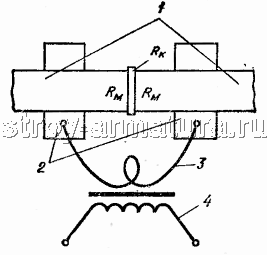

The essence of the process of contact butt welding is as follows. The electrical current is connected to the welded rods and, leading the latter into contact, form a closed electrical circuit (Fig. 11).

Figure 11. Electric circuit with butt pin welding

1 - welded rods; 2 - clamping sponges; 3 - secondary coil of the welding transformer; 4 - primary winding of the welding transformer; RM - resistance to welded rods; RK - contact resistance

In this chain, the largest flow resistance has a junction of the rods, therefore, in this place will be the most intensively highlighted heat, which will warm up the ends of the rods to plastic, and partially before the liquid state.

There are two ways of contact welding:

shock contact welding continuous melting

shock contact welding with intermittent adheated melting.

Contact butt welding of the rods of hot-rolled fittings made of steel classes A-2 ... A-4 (in any combination) should be carried out by the method of intermittent melting with heating. Armature from steel class A-1 must be welded by a continuous refueling method; With insufficient power of the machine, they can also be welded by a heated melting.

To form an initial electric current on the ends of the reinforcement, it is necessary to remove the paint or rust from them. If the reinforcement rods were trimmed with a gas flame, their ends are pre-cleaned from the slag crust with a chisel or hammer. The quality of the welded joint compounds is influenced by the purity of the surface of the rod touches with clamping sponges of the machine.

The contact butt welding mode should ensure that there are equalized rods of welded compounds with minimal electricity and time consumption.

The main parameters of the welding mode are: current or its density, current flow period, precipitation pressure, as well as the installation length, i.e. The size of the ends of the rods protruding from the electrodes.

Depending on the current density (current on mm2 of the surface), two connecting modes of butt contact welding are distinguished:

hard mode characterized by a large current density of a small period of time (for small diameter rods),

soft mode with low current density over a long period (for large diameter rods).

Current density when welding continuous melting -10 ... 50 A / mm2. The duration of the current flow ranges from 1 to 20 s, depending on the diameters of the reinforcement rods; With increasing diameter, the current flow rate increases.

For the quality of the weld joint, the specific precipitation pressure on the end of the rod (kg / mm2) is also It is selected depending on the class of steel. Specific precipitation for steel class A-1 takes 30 ... 50 MPa, class A-2 and A-3 - 60 ... 80 MPa. The force of compression of the reinforcement rods during heating should be 10 ... 12% of precipitation pressure. The duration of the closures and opening of the arc in the preparation of the rod to welding is selected in the range of 0.3-0.8 s.

Figure 12. Appearance of butt compounds of fittings made by contact electric welding with proper (A) and incorrect (b) welding modes

From the correctness of the selection of welding mode, approximately judged by appearance welded connections (Fig. 12). With the correct mode of butt contact welding, the ends of the reinforcement rods are sufficiently warmed up and with mutual compression, the shape shown in the figure is purchased. Confirmation of the correctness of the selected mode can be obtained only after laboratory tests of welded connections for strength.

In the process of operation, the welder must observe the state of contact lips and periodically clean them from the emerging car. You must have a set of sponges of various shapes and sizes to avoid possible breaks in operation when changing the diameters of the welded fittings.

Figure 13. Template for checking the mixing axes of rods in the joints performed by contact welding

Cooked rods must be straightforward. The displacement of the axes of the rods in the joints is allowed not more than 0.1 of their diameter. The length of the rod is measured with an accuracy of 1 mm. The displacement of the axes at the place of the joint is determined by a special template (Fig. 13). In addition to external inspection, the location of the reinforcement is closed with a hammer weighing 1 kg; At the same time, a rattling sound should not occur.

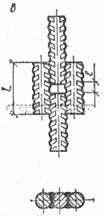

Production of mortgage details

Mortgage parts are made from reinforcement rods and rolled (sheet and profile). Apply soft, well-weldable steel, usually the SB and V group of group B and V. One of the common is a mortgage part consisting of a steel plate and a reinforcement rod welded with a taving compound (Fig. 14).

Fig. 14. Taurus connection of anchor rod with a flat element of a mortgage part with a hole-based holes

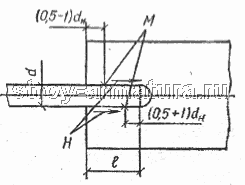

The rod with the plate is welding with the welding machines of the ADP-2001-Thor4 type. For a stagnation of a rod with a plate, a manual arc welding is used through a predetermined hole. After welding, the seam is cleaned with a flush with a plane plane. You can connect the plate with the rod in the horizontal plane (Fig. 15).

Fig. 15. Connections of rods with flat elements in the horizontal plane

N - directions of surfacing of seams; M - places tapes

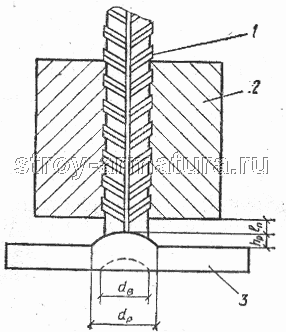

Often the brand compound of the reinforcement rod with the steel plate is carried out using relief welding. In this case, contact relief welding can be performed in the end, i.e. The rod is welded perpendicular to the plane of the plate (Fig. 16) and the pectorist. Reliefs on the plates are obtained using mechanical presses or press scissors. Reliefs in shape are round or cylindrical, but by the number of single or double. The welding mode is chosen depending on the thickness of the connected elements of the mortgage part and the number of welding points.

Fig. 16. Taurope compound contact relief welding

1 - reinforcement rod; 2 - electrode; 3 - flat element of mortar parts; DB - the diameter of the recess; DR - the domain base diameter; DN - rod diameter; HP - the elevation of the relief; LP - Rod departure from electrode

If it is impossible to use the contact welding to use the contact welding to be applied. With the help of welding, a connection of mortgage parts with elements of reinforcement structures is carried out. Depending on the class and steel grade, the positions of the axes of the connected elements and the type of seam (horizontal, vertical, lower) select the welding method: contact (point, relief), bath, arc (multi-power, multi-layer, point, suture under flux).

Developed new constructive and technological solutions related to the manufacture of mortgage parts. Stamped and stamped-welded mortgage parts appeared, which allowed 1.5-2 times to reduce the consumption of steel and increase labor productivity several times. The stamped mortgage detail is a product in which the plate (table) and the anchor (rod) are one integer. The special stamp is cut down from the same strip. The bend of the launched strips (anchors) and the plates are carried out by bending stamps. Making stamped mortgage parts. Can be fully automated. The technological process for the production of stamped parts includes: cutting; Punching holes; relief disembarka (puppy); Non-cut anchors; flexible; Metallization. Some operations can be combined, such as cutting, breaking holes and relief landing. The big effect also gives the combination of stamping and welding of mortgage parts. In this case, the anchor with welding is combined with a specially prepared stamping relief plate.

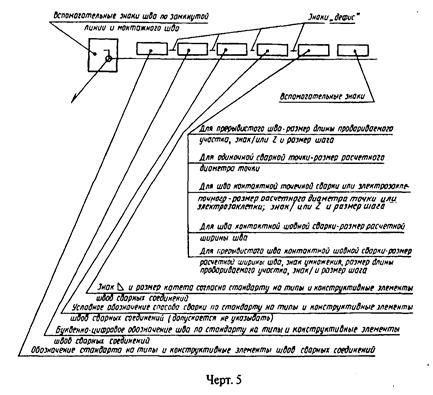

5. Conditional images and designations of welded joints in design documentation

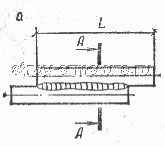

invisible - dash line ( heck. 1G.).

Visible single welded point, regardless of the welding method, conditionally depict the "+" sign ( heck. 1B), which is performed by solid lines ( heck. 2.).

Invisible single points are not depicted.

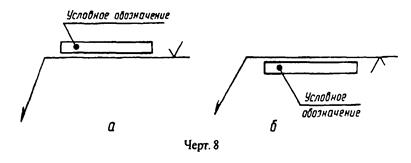

From the image of a seam or a single point, a tuning line, ending with a one-sided arrow (see heck. one). The tuning line is preferably carried out from the image of the visible seam.

Conditional designations of welded joints

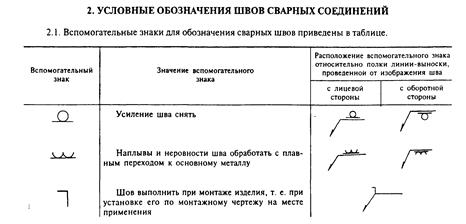

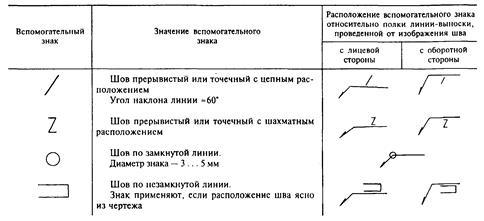

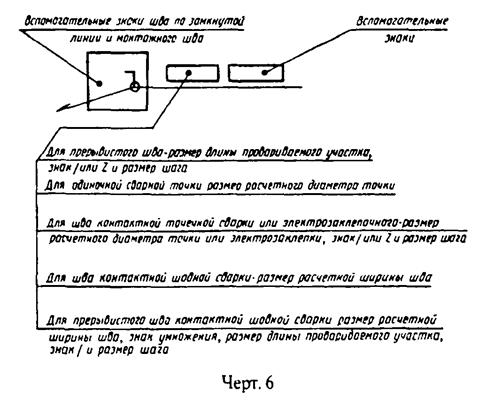

Auxiliary signs for the designation of welds

Notes:

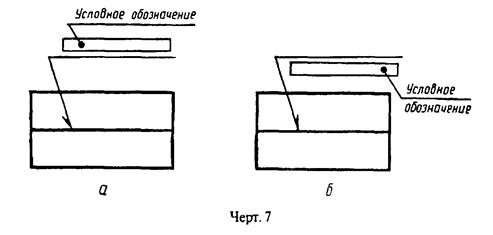

1. During the front side of the one-sided seam of the welded joint, the side is taken from which welding is produced.

2. For the front side of the two-sided welded joint with asymmetrically prepared edges, the side is taken from which the main seam welding is produced.

3. For the front side of the two-sided welded joint with symmetrically prepared edges, any side can be accepted.

In the conventional designation of the seam, the auxiliary signs are performed by solid thin lines.

Auxiliary signs should be the same height with numbers included in the designation of the seam.

Sign | _ \\ Perform with solid thin lines. The height of the sign should be the same with the height of numbers included in the designation of the seam.

The technical requirements of the drawing or the seam table indicate the welding method that the non-standard seam must be performed.

Note. The content and dimensions of the seam table graph are not regulated by this standard.

The technical requirements or table of the seams in the drawing lead a reference to the appropriate regulatory and technical document.

Welding materials are allowed not to indicate.

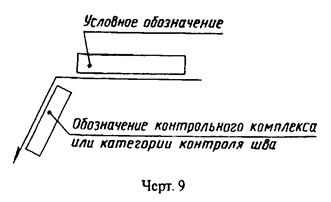

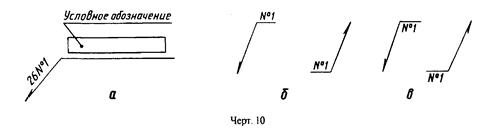

The number of identical seams is allowed to be indicated on a lifting line having a shelf with applied designation (see heck. 10 A.).

Note. The seams are considered the same if:

their types and dimensions of structural elements in cross section are the same;

these are the same technical requirements.

List of used literature

1. Digital arc welding, the book is written by a team of authors: Chapter 25 IG. Getya, the remaining chapters - V. and, Melnik with the participation of B.D. Malyshev

2.Alekseev E.K., Melnik V.I. Welding in industrial construction - m Stroyzdat, 1977 -377 with

3. Maleshin N.P. Shcherbinsky V.G. Quality control of welding work - Mossev School, 1986 - 167 with

4.Http: //www.stroy-armatura.ru.

5. MENT-state standard GOST 2.312-72 * "Unified system of design documentation. Conditional images and designations of welded joints "(appliance. Resolution of the State Committee of Standards of the Council of Ministers of the USSR on May 10, 1972 No. 935)

There are the following main types of welded compounds: butt, ingestion, brass, corner, slit, end, with overlays, electric plates.

The butter compounds (Fig. 10) are the most common in almost all welding methods, as they give the smallest eigenvators and deformations during welding (see the Welding deforming and voltages, see chapter VIII).

The butt compounds are mainly used for sheet metal structures. They require the smallest consumption of the main and weld metal and welding time, can be made equal main metal. However, when performing butt connections, careful and fairly accurate preparation of sheets for welding and fit to each other are needed.

With manual arc welding of steel sheets with a thickness of 4-8 mm, the edges can be trimmed at a right angle to the surface. In this case, the sheets are placed with a gap of 1-2 mm.

Without the edge of the edges, you can "weld the sheets of sheets up to 3 mm with a one-sided and up to 8 mm with double-sided welding.

Sheets thick from 4 to 26 mm with manual arc welding are connected to a joint with one-sided bevel of edges. This type of edge preparation is called V-shaped. Sheets with a thickness of 12-40 mm and are more connected with two-sided bevel edges, called x-shaped.

The dullness of the edges is done in order to prevent metal flow during welding (burr). The gap between the welded edges is left to facilitate the province of the seam root (lower parts of the edges). Great importance For welding quality, it has the preservation of a uniform width of the gap along the entire length of the seam, i.e., compliance with the parallelism of the edges.

Two-fusion edges of the edges (X-shaped) has the advantages over one-way (V-shaped), since with the same thickness of the welded sheets, the volume of the weld metal will be

two times less than with unilateral edges. Accordingly, the flow rate of electrodes and electricity during welding will decrease. In addition, the two-way edges of the edges gives smaller strokes and residual stresses during welding than one-sided

With manual arc welding, the thickness of the bevel between the edges can be reduced from 60 to 45 ° with a thickness of over 20 mm. The gap between the dumps of edges should be 4 mm, which facilitates the proper provider of them. The decrease in the angle of the edge of the edges leads to a reduction in the volume of the weld metal, and therefore, to an increase in the performance of welding and saving electrodes.

The edges of the sheets of unequal thickness connected into the joint are mounted as shown in Fig. 10, B, and a thicker leaf is mounted to a greater extent.

When combining the steel of large thicknesses in order to reduce the amount of deposited metal, they resort to a number of cases to a cup-shaped form of edge preparation: for thicknesses from 20 to 50 mm-one-sided, and over-one-sided (Fig. 10, B).

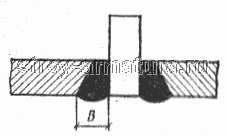

Connections into a navel (Fig. 11, a) find the preferential use in arc welding of building structures from steel thickness not more than 10-12 LSh. They do not require special processing of edges, except for their trimming. With this connection, it is recommended to welded sheets on both sides, since it is possible to enter the gap between the sheets and the subsequent rust of the metal in this place.

The assembly of the product and the preparation of sheets during welding in the fastest is simplified, however, the consumption of the main and weld metal is greater than when welding into the joint. With roller and point contact electric welding, connections are used only to a lamb.

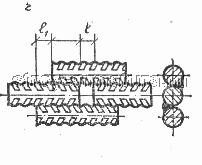

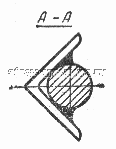

Taurus compounds (Fig. 11, b) are widely used in arc welding; They are performed without a bevel of edges and with the bevel edges on one side or on both sides. The vertical sheet should have a fairly circumcised edge. With one-sided and double-sided module edge of the vertical sheet between vertical and horizontal sheets, a gap in 2-

3 mm for better provider of vertical sheet for full thickness. One-sided beep is used if the design of the product does not allow welding a taving connection on both sides.

The angular compounds are used during welding of different pre-treated edges of the sheets and are shown in Fig. 11, c. The welded parts are located at a direct or other angle and welded along the edges. Such compounds are used primarily when welding tanks operating under insignificant internal gas pressure or fluid. Sometimes the angular compounds coherent also from the inside, as shown by the dotted line in Fig. 11, in (left).

The sloping compounds (Fig. 11, d) are used when the length of the normal seam in the filament does not provide

|

|

|

|

Fig. 12 Welded joints: A - end, or side, b-with overlays, in - electroslacking //

accurate strength. Sitting connections are closed or open. The slot is usually performed by oxygen sharp.

Next, or side, connections are shown in Fig. 12, a. Sheets are connected to their surfaces and welded on adjacent ends.

Connections with overlays are shown in Fig. 12,

b. Pad 2, overlapping the sheet of sheets 1 and 3, welded along the side edges to the surface of the sheets. These compounds require an additional metal consumption on the lining and therefore apply only in cases where they cannot be replaced by butt or thicket connections for any reason.

The compound of electroslacks is shown in Fig. 12, e. With the help of electrosulatures, durable, but not dense connections are obtained. The top sheet is drilled and the hole is brewed so that the bottom sheet is captured. With automatic welding under the flux, the upper sheet, if its thickness is small, is not previously drilled and it is adjusted by a welding arc.

The compounds described are typical for manual arc welding of steel. In gas welding, welding under flux, welding of low-melting non-ferrous metals and in other cases, the shape of the edges can be different. The corresponding information about them will be given in subsequent chapters when describing these welding methods.

Welded seams are divided into the following groups:

1. On the position in space - the bottom, horizontal, vertical and ceiling (Fig. 33, C). The simplest suture is the simplest seam, and the most difficult - ceiling. Poto / woven seams can perform welders, specially mastered this type of welding. Perform ceiling seams Arc welding is harder than gas. The welding of horizontal and vertical seams on the vertical surface is somewhat more complicated than the welding of the lower seams.

2. In relation to the current efforts - flank, end, or windy, combined n oblique (Fig. 13, b).

3. Under the length - continuous, or solid, and intermittent (Fig. 13, B). Intermittent seams are used in cases where the compound should not be dense, and according to the calculation of strength, a continuous seam is required.

For intermittent seam, the length of the individual sections of it (/) is from 50 to 150 mm; The distance between the seam sections is usually 1.5-2.5 times the length of the site; The value of T is called W A - G O M SWU. Intermittent seams are used quite widely, as they give savings of the weld metal, the cost and time of welding.

4. According to the degree of bulge - normal, convex and concave (Fig. 13, d). Switching seam A "Depends on type

|

|

a- according to the position in space, B - with respect to the current effort, in the extent of STN, G- according to the degree of convexity of the surface of the seam

applicable electrodes: thin-plated electrodes give seam with large convexity; With thick-coated electrodes, due to the larger ZPDKOTEC, normal seams are usually obtained.

|

|

Studies have shown that seams with large convexity do not increase the strength of the seam, especially if the welded compound is subjected to variable loads and vibrations. This is explained by the fact that under seams with a large convexity, it is impossible to obtain a smooth transition from the seam roller to the main metal and in this place it is formed something like "subside" the edge of the seam, where there is a significant concentration of stresses.

Therefore, under the action of variables, shock or vibratory loads from this place, the destruction of the welded joint may begin. Suts with large convexity are uneconomical, since more electrodes, time and electricity are consumed on their execution.

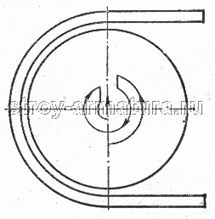

5. By type of compound - butt and angular (rollers

Fig. 14, corner (valikovyi) seams]. Corner seams apply - "

with junctions in fruit, in bulk, corner connections and connections with overlays. The side to the angular seam (Fig. 14) is a cathe. The Shaded Square ABBG characterizes the degree of convexity of the seam compared with normal and is not taken into account when determining the strength of the welded joint. The angular seams are carried out so that their catts are equal, i.e. ov-og \u003d k. The angle between the sides of the OG and Vg is 45 °.