Welded joints and seams are classified according to the following main characteristics:

- type of connection;

- the position in which welding is performed;

- configuration and length;

- type of welding used;

- a method for holding molten weld metal;

- number of layers;

- material used for welding;

- the location of the welded parts relative to each other;

- the force acting on the seam;

- volume of deposited metal;

- form of welded structure;

- the shape of the prepared edges for welding

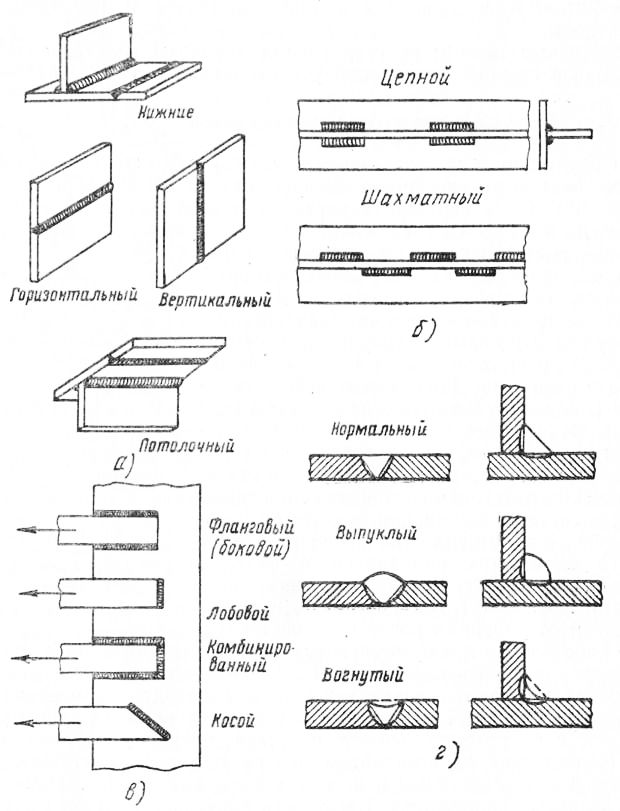

By the type of connection, welds are butt and fillet. Seams in space welded joints are divided into lower, vertical, horizontal and ceiling. The exit of the seam from the ceiling to the vertical position when welding cylindrical products is called a semi-ceiling position.

According to the configuration, the seams of welded joints are rectilinear, circular, vertical and horizontal. By the length of the seams are divided into solid and intermittent. Solid seams, in turn, are divided into short, medium and long.

By type of welding, the seams of the welded joints are divided into:

- arc welding seams

- seams of automatic and semi-automatic submerged arc welding

- shielded arc welding seams

- electroslag welding seams

- electrowelded seams

- resistance welding seams

- seams of soldered joints

According to the method of holding molten metal, the seams of welded joints are divided into seams made without linings and pillows; on removable and remaining steel linings: on copper, fluxed. ceramic and asbestos linings, as well as flux and gas pads. Depending on which side the seam is laid on, one-sided and two-sided seams are distinguished.

According to the material used for welding, welds of welded joints are divided into welds of joints of carbon and alloy steels; non-ferrous metal joints; bimetal joints; seams of connection of vinyl plastic and polyethylene.

According to the location of the parts to be welded relative to each other, the seams of the welded joints can be at an acute or obtuse angle, at a right angle, and also be located in the same plane.

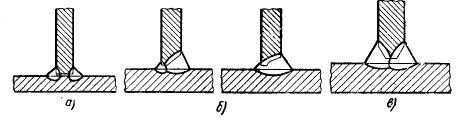

The volume of deposited metal distinguish between normal, weakened and reinforced seams.

According to the shape of the structure being welded, the joints of welded joints are made on flat and spherical structures, and according to the location on the product, the joints are longitudinal and transverse.

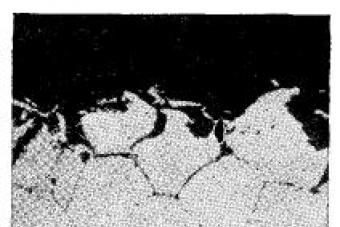

Welded are called one-piece joints made by welding. They can be butt, corner, lap, tee and end (Fig. 1).

A joint is called the connection of two parts with their ends located in the same plane or on the same surface. The thickness of the surfaces to be welded may be the same or differ from one another. In practice, a butt joint is most often used in welding pipelines and various tanks.

Angular - a welded joint of two elements located at an angle relative to each other and welded at the junction of their edges. Such welded joints are widely used in construction practice.

Lap-welded connection involves the imposition of one element on another in the same plane with a partial overlap of each other. Such compounds are most often found in construction and installation works, during the construction of farms, tanks, etc.

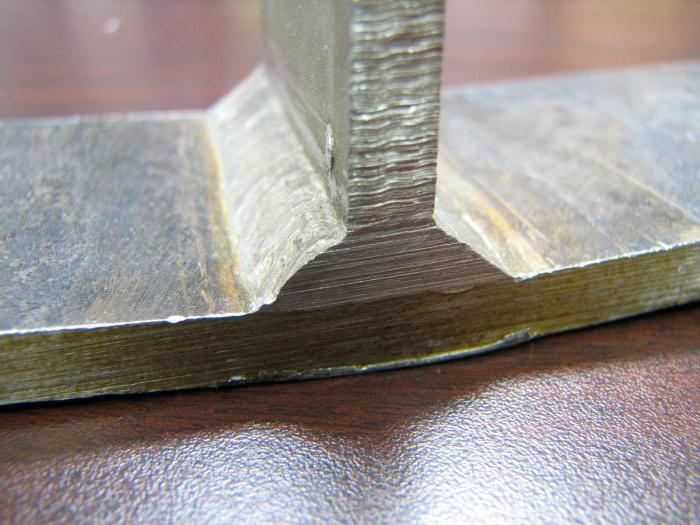

A T-joint is a joint in which the end face of another joint is attached to the plane of one element at a certain angle.

Welding seams

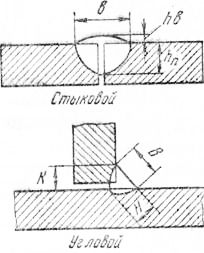

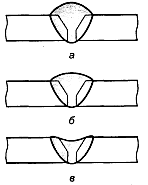

A weld portion formed as a result of crystallization of molten metal is called a weld. Unlike joints, welds are butt and fillet (Fig. 2).

A butt joint is a weld of a butt joint. Corner is a weld of angular, lap joint and T-joints.

Welds are distinguished by the number of layers of overlap, their orientation in space, length, etc. So, if the seam completely covers the joint, then it is called solid. If the seam is torn within one joint, then it is called intermittent. A kind of intermittent seam is the tack seam, which is used to fix the elements relative to each other before welding. If welding seams imposed one on top of another, then such seams are called multilayer.

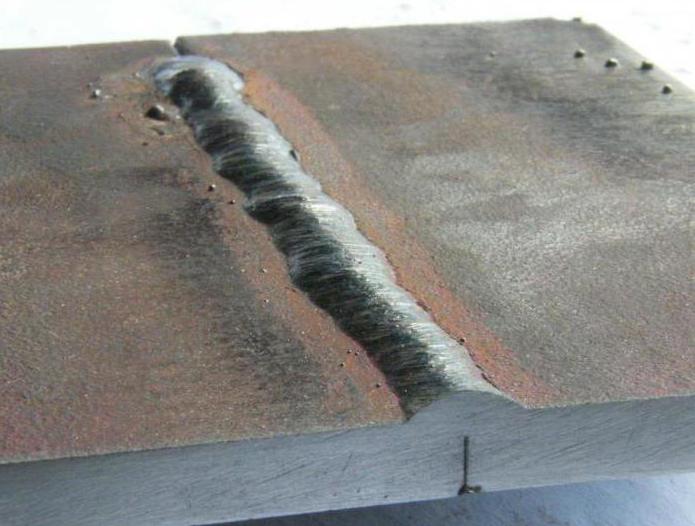

The shape of the outer surface of the welds can be flat, concave or convex. The shape of the weld has an effect on its physical and mechanical properties and on the consumption of electrode metal associated with its formation. The most economical are flat and concave seams, which, moreover, work better under dynamic loads, since there is no abrupt transition from the base metal to the weld. Excessive influx of convex seams leads to an excessive consumption of electrode metal, and a sharp transition from the base metal to the weld at concentrated stresses can cause destruction of the joint. Therefore, in the manufacture of critical structures, the bulge at the seams is removed mechanically (cutters, abrasive wheels, etc.).

Distinguish welds by their position in space. These are the bottom, horizontal, vertical and ceiling seams.

Elements of the geometric shape of the preparation of the edges for welding

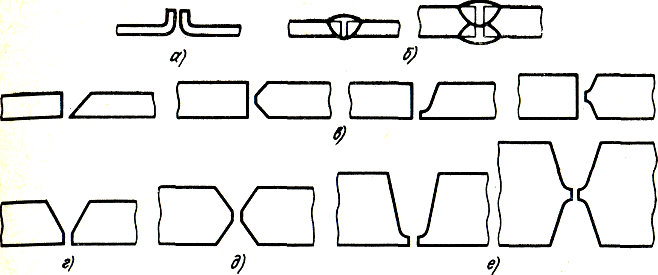

Elements of the geometric shape of the preparation of the edges for welding (Fig. 3, a) are: the angle of cutting edges α; the gap between the abutting edges a; blunting edges S; the bevel length of the sheet L in the presence of a difference in the thickness of the metal; displacement of the edges relative to each other δ.

The angle of cutting edges is performed with a metal thickness of more than 3 mm, since its absence (cutting edges) can lead to lack of penetration in the welded joint section, as well as to overheating and burning of the metal; in the absence of cutting edges to ensure penetration, the welder always tries to increase the value of the welding current.

Cutting the edges allows welding in separate layers of a small cross section, which improves the structure of the welded joint and reduces the occurrence welding voltage and deformations.

The gap, correctly set before welding, allows for full penetration over the connection cross section when applying the first (root) layer of the seam, if the appropriate welding mode is selected.

The length of the bevel of the sheet regulates a smooth transition from a thick welded part to a thinner, stress concentrators in welded structures are eliminated.

The blunting of the edges is performed to ensure stable conduct of the welding process when performing the root layer of the seam. The lack of blunting contributes to the formation of burns during welding.

Edge displacement worsens the strength properties of the welded joint and contributes to the formation of lack of penetration and stress concentrations. GOST 5264-69 allows displacement of the welded edges relative to each other up to 10% of the metal thickness, but not more than 3 mm.

Geometry and classification of welds

The elements of the geometric shape of the weld are: for butt joints - weld width "b", weld height "h", for T-joints, corner and lap joints - weld width "b", weld height "h" and weld leg "K" (Fig. . 3, b).

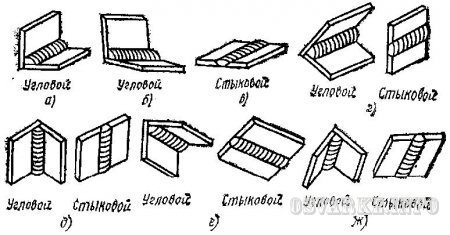

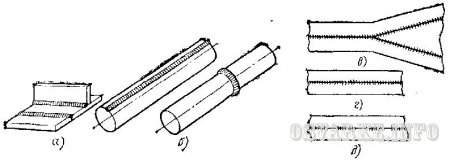

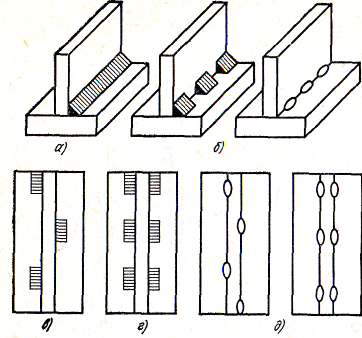

Welds are classified by the number of weld beads — single-layer and multi-layer (Fig. 4, a); by location in space - lower, horizontal, vertical and ceiling (Fig. 4, b); in relation to the current efforts at the joints - flank, frontal (butt) (Fig. 4, c); in the direction - rectilinear, circular, vertical and horizontal (Fig. 4, d).

Weld Properties

The quality indicators of welded joints are affected by many factors, which include the weldability of metals, their sensitivity to thermal influences, oxidizability, etc. Therefore, in order to meet welded joints with one or another operational conditions, these criteria should be taken into account.

The weldability of metals determines the ability of individual metals or their alloys to form compounds corresponding to specified parameters with appropriate processing. This indicator is influenced by the physical and chemical properties of metals, the structure of their crystal lattice, the presence of impurities, the degree of alloying, etc. Weldability can be physical and technological.

Physical weldability is understood to mean the property of a material or its compositions to create a monolithic compound with a stable chemical bond. Almost all pure metals, their technical alloys, and a number of combinations of metals with nonmetals possess physical weldability.

The technological weldability of a material includes its reaction to the welding process and the ability to create a joint that satisfies the given parameters.

§ 5. Classification welds

Welds are classified according to the following main features. By mind welded joints distinguish between butt and corner seams. Seams located in butt welded joints are called butt, located in T-joints, angles and lap joints - angular.

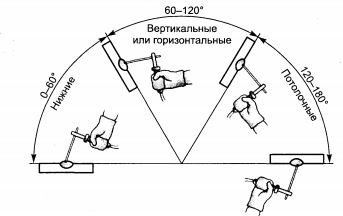

By position in which welding is performed, the welds are: “into the boat”, lower, semi-horizontal, horizontal, semi-vertical, vertical, semi-ceiling and ceiling (Fig. 6).

Fig. 6. Classification of welds by location in space:

a - lower "into the boat", b - lower corner, c - lower butt, d - horizontal, d - vertical, e - semi-ceiling, w - ceiling

By configuration seams of welded joints are rectilinear, circular and curvilinear; in length - continuous and intermittent. Solid seams, in turn, are divided into short, medium and long (Fig. 7).

Fig. 7. Classification of welds by configuration and length:

a - rectilinear, b - circular, c - curvilinear, d - continuous, d - intermittent

By type of welding used seams of welded joints are divided into seams of manual arc welding, seams of automatic and mechanized submerged-arc welding, seams of arc welding in shielding gases, seams of electroslag welding, seams of electro-rivets, seams of contact electric welding, seams of gas welding, seams of soldered joints.

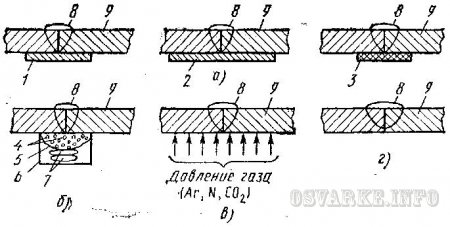

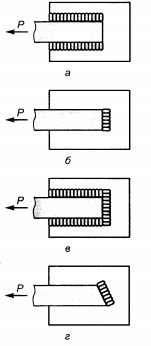

By retention method during welding, the welds of the welded joints are divided into joints made without linings and pillows, on removable and remaining steel linings, on copper, flux-honey, ceramic and asbestos linings, as well as flux and gas pillows (Fig. 8).

Fig. 8. The scheme of seams:

a - on linings, b - on a flux pad, c - with gas injection, g - by weight;

1 - removable copper lining, 2 - remaining steel lining, 3 - asbestos lining, 4 - flux, 5 - tarpaulin, 6 - metal box, 7 - air hoses, 8 - weld, 9 - welded product

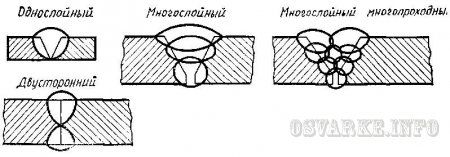

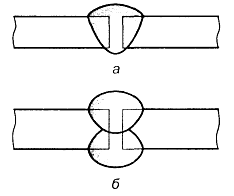

By number of layers and rollers, welds are: unilateral, bilateral, multilayer and multilayer multipass (Fig. 9).

Fig. 9. Classification of welds by the number of layers and rollers

By material used for welding seams of welded joints are divided into seams of joints of carbon and alloy steels, seams of joints of non-ferrous metals, seams of joints of bimetal, joints of joints of vinyl plastic and polyethylene.

By the location of the welded parts relative to each other, the seams of the welded joints can be at an acute or obtuse angle, at a right angle, and also be located in the same plane.

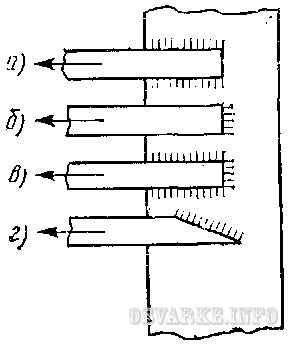

By force applied to the seam seams are flank, frontal, combined and oblique (Fig. 10).

Fig. 10. Classification of joints according to the force acting on them:

a - flank, b - frontal, c - combined, d - oblique

By volume of weld metal Distinguish between normal, weakened and reinforced seams (Fig. 11).

Fig. 11. Classification of welds by volume of weld metal

By form of welded construction welded joints are performed on flat and spherical structures, according to location on the product distinguish between longitudinal and transverse seams.

Weld classification

TO category:

Welded joints

Weld classification

Welds are divided by type of weld and the geometric shape of the weld section into butt and corner. A butt weld is characterized by width (b) and reinforcement LV, penetration depth hn, angular — Cathet K, width B, and thickness H. Butt welds are used to make butt, butt, flanged, and sometimes angular joints. Corner seams are used in lap, tee and corner joints. The dimensions of the cross-section of the seams are established by GOST 5264-69.

According to the shape of the outer surface, the butt joints may be flat or convex. Corner joints can also be concave. Welded joints with convex seams work better for static loads than joints with flat or concave seams. However, seams with too much bulge due to the large amount of deposited metal are uneconomical. Butt joints with flat seams and corner, tee and lap joints with concave seams work better for dynamic or alternating loads than joints with convex seams. This is due to the fact that with flat and concave seams there are no abrupt transitions from the base to the weld metal, in which there is a concentration of stresses and from which joint destruction can begin. In accordance with the standard, weld convexity is allowed for lower welds up to 2 mm and not more than 3 mm for welds made in other positions. Concavity is allowed in all cases no more than 3 mm.

According to the position in space, the seams are lower, vertical, horizontal and ceiling.

Fig. 1. Classification of welds according to the geometric outline

Welding the lower seams is most convenient, easy to mechanize. The most complicated and difficult is the ceiling seam, the implementation of which requires special training. Performing horizontal and vertical seams on a vertical plane is not much more difficult than lower ones, but lighter than ceiling ones. In most cases, vertical, horizontal, and ceiling joints are used in the construction and installation of large structures and much less often in factory conditions, where with the help of fixtures it is possible to almost completely weld the structure only in the lower position. Many highly qualified welders perform vertical seams with better quality than the lower ones, since in this case the dirt is easier to remove from the weld pool and the weld metal becomes cleaner, denser and stronger.

Fig. 2. Classification of welds: a - according to the position in space, b - along the length, e - in relation to the direction of the acting forces, d - according to the shape of the outer surface

In relation to the direction of the acting forces, the seams are divided into flank (side) and longitudinal, the axes of which are parallel to the direction of the force; frontal, the axes of which are perpendicular to the direction of the force; combined and oblique.

According to the length, continuous and intermittent seams are distinguished. An intermittent seam can be chain or staggered. The chain seam is a two-sided intermittent seam of the T-joint, in which the welding sections and the gaps are located on both sides of the wall one against the other. Chess seam is a two-sided intermittent seam of a T-joint, in which the gaps on one side of the wall are located against the welded sections of the seam on the other side. The distance from the beginning of the welded seam section to the beginning of the next section is called the seam pitch. Intermittent seams are used in joints that do not require tightness (impermeability) and when solid seams are lightly loaded. Welded joints with continuous welds better withstand alternating loads and are less susceptible to corrosion than joints with intermittent welds. Particularly responsible welded products, as a rule, are performed with continuous seams.

According to the working conditions, the seams are divided into workers who perceive external loads, and binders (connecting seams), intended only for fastening parts of the product. Bonding seams are often called non-working seams.

Terms and definitions for welded structures, assemblies, joints and seams are established by GOST 2601-84.

A welded joint is an inseparable connection of two or more elements (parts) made by welding. The welded joint includes the weld, the adjacent zone of the base metal with structural and other changes as a result of the thermal action of the weld (heat affected zone) and adjacent sections of the base metal.

A weld is a section of a weld formed as a result of crystallization of molten metal or as a result of plastic deformation during pressure welding or a combination of crystallization and deformation.

A welded assembly is a part of a welded structure in which adjacent elements are welded.

A welded structure is a metal structure made of individual parts or assemblies by welding.

The metal of the parts to be joined by welding is called the base metal.

The metal supplied to the arc zone in addition to the molten base metal is called a filler metal.

Remelted filler metal introduced into the weld pool or welded onto the base metal is called weld metal.

The alloy formed by the remelted base or base and weld metals is called the weld metal.

The operability of a welded product is determined by the type of welded joint, the shape and size of the welded joints and seams, their location relative to the acting forces, the smooth transition from the weld to the base metal, etc.

When choosing the type of welded joint, operating conditions (static or dynamic loads), the method and conditions for manufacturing the welded structure (manual welding, automatic in the factory or installation conditions), the saving of the base metal, electrodes, etc. are taken into account.

Types of welded joints. The following types of welded joints are distinguished by the form of mating of the connected parts (elements): butt, corner, tee, lap (Figure 1).

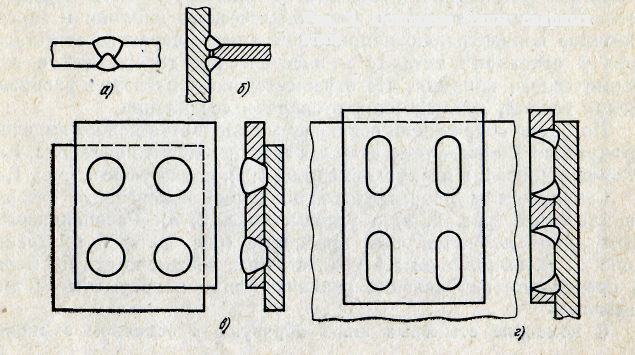

Welds are divided according to the shape of the cross section into the butt welds (Figure 2, a) and corner (Figure 2, b). A variety of these types are cork seams (Figure 2, c) and grooves (Figure 2, d), performed in lap joints. According to the shape in the longitudinal direction, seams are continuous and intermittent.

Via butt welds mainly form butt joints (Figure 1, a), using fillet welds - T-joints, cross, corner and lap joints (Figure 1, b-d), with the help of cork and slotted joints, lap and sometimes T-joints can be formed.

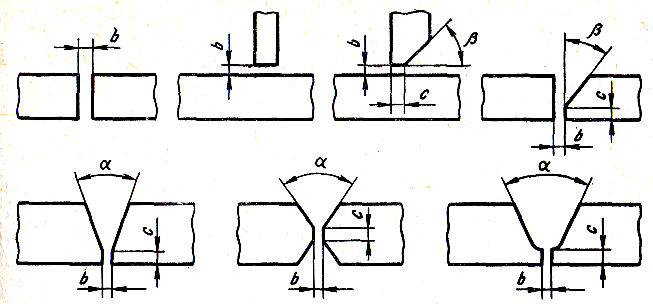

Butt welds are usually continuous; a distinctive feature for them is usually the shape of the cutting edges of the connected parts in cross section. On this basis, the following main types of butt welds are distinguished: with flanging of the edges (Figure 3, a); without cutting edges - one-sided and two-sided (Figure 3, b); with cutting of one edge - one-sided, two-sided; with a rectilinear or curvilinear form of cutting (Figure 3, c); with one-sided cutting of two edges; with a V-shaped groove (Figure 3, d); with bilateral cutting of two edges; X-shaped cutting (Figure 3, e). The groove can be formed by straight lines (bevel edges) or have a curved shape (U-shaped groove, Figure 3, f).

a) butt; b, c) Tauri; d) angular; d) lap

Figure 1 - The main types of welded joints

a) butt; b) angular; c) cork; g) slotted

Figure 2 - The main types of welds

Butt joint is most common in welded structures, as it has several advantages over other types of joints. It is used in a wide range of thicknesses of parts to be welded from tenths of a millimeter to hundreds of millimeters in almost all welding methods. At butt joint less filler material is spent on the formation of a seam, and quality is easily and conveniently controlled.

a) with flanging edges; b) without cutting edges;

c, d, e, e) with grooves

Figure 3 - Preparation of the edges of the butt joints

Corner seams are distinguished by the form of preparation of the welded edges in the cross section and the continuity of the seam along the length.

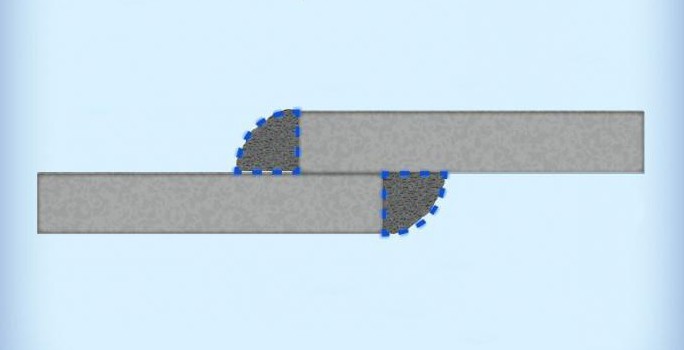

According to the cross-sectional shape, fillet welds can be without cutting edges (Figure 4, a), with one-sided cutting of edges (Figure 4, b), with bilateral cutting of edges (Figure 4, c). The length of the fillet welds can be continuous (Figure 5, a) and intermittent (Figure 5, b), with a staggered (Figure 5, c) and chain (Figure 5, d) arrangement of the seam segments. T-joints, lap joints and corner joints can be made by segments of seams of small length - spot welds (Figure 5, e).

Cork seams in their shape in plan (top view) are usually round in shape and are obtained as a result of full penetration of the upper and partial penetration of the lower sheets (Figure 6, a) - they are often called electric rivets, or by penetration of the upper sheet through previously done in the upper sheet hole (Figure 6, b).

a) without cutting edges; b, c) with cutting edges

Figure 4 - Preparation of the edges of the fillet welds

compounds

Figure 5 - Corner joints of T-joints

Figure 6 - Cross-sectional shape of cork and

welded seams

Grooved seams, usually of elongated shape, are obtained by welding the upper (covering) sheet to the lower corner seam around the perimeter of the slot (Figure 6, c). In some cases, the slot can be filled completely.

Four basic structural elements characterize the shape of the cutting edges and their assembly for welding (Figure 7): clearance b, blunting c, bevel angle  and edge angle

and edge angle  equal to

equal to  or 2

or 2  .

.

Existing methods of arc welding without cutting edges allow you to weld metal of limited thickness (for manual welding on one side - up to 4 mm, mechanized submerged arc welding - up to 18 mm). Therefore, when welding metal of large thickness, it is necessary to cut the edges. The angle of the bevel of the edge provides a certain value of the angle of cutting the edges, which is necessary for the arc to go deeper into the joint and to completely penetrate the edges to their entire thickness.

The standard angle of cutting edges depending on the welding method and type of connection varies from 60 ± 5 to 20 ± 5 degrees. The type of cutting and the value of the angle of cutting the edges determine the amount of additional metal needed to fill the cutting, and therefore, the productivity of welding. So, for example, the X-shaped cutting of the edges in comparison with the V-shaped allows to reduce the volume of deposited metal in 1.6 - 1.7 times. Edging time is reduced. True, in this case there is a need to conduct welding on one side of the seam in an uncomfortable ceiling position or turn over the welded products.

The blunting is usually 2 ± 1 mm. Its purpose is to ensure proper formation and prevent burns at the top of the seam. The gap b is usually equal to 1.5-2 mm, since at the accepted corners of cutting edges, the presence of a gap is necessary for penetration of the top of the seam, but in some cases with a particular technology, the gap can be zero or reach 8-10 mm or more.

For all types of seams, complete penetration of the edges of the connected elements and the external shape of the seam both from the front side (reinforcement of the seam) and from the back side, i.e. the shape of the reverse roller, are important. In butt, especially one-sided seams, it is difficult to weld the blunting edges to their entire thickness without special techniques that prevent burn through and ensure good formation of the back roll.

Figure 7 - Structural elements for cutting edges and

welding assemblies

Welds are classified according to a number of signs. In appearance, the seams are divided into convex, normal, concave (Figure 8). Usually all

seams are made with slight reinforcement (convex). If joints without reinforcement are required, this should be indicated on the drawing. Weakened (concave) perform fillet welds, which is also noted in the drawing. Such seams are required to improve the performance of welded joints, for example at variable loads. Butt joints do not weaken, concavity in this case is a marriage. An increase in the size of welds in comparison with the given ones leads to an increase in the mass of the welded structure and an excessive consumption of electrodes. As a result, the cost of welded structures increases, the complexity of welding works increases.

a) convex; b) normal; c) concave

Figure 8 - Classification of seams in appearance

Of great importance is also the formation of a smooth transition of the metal of the front and reverse rollers to the base metal, as this provides high strength joints under dynamic loads. In fillet welds, it can also be difficult to weld the root of the seam over its entire thickness, especially when welding with an inclined electrode. For these seams, a concave cross-sectional shape of the seam with a smooth transition to the base metal is recommended, which reduces the stress concentration at the transition point and increases the strength of the joint under dynamic loads.

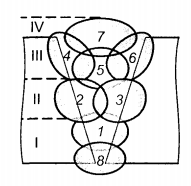

According to the number of layers and passages, single-layer, multi-layer, single-pass, multi-pass seams are distinguished (Figure 9, 10).

A weld layer is a part of the weld metal, which consists of one or more rollers located at the same level of the weld cross section. Roller - weld metal deposited or remelted in one pass.

Figure 9 - Classification of seams by execution: a - one-sided; b - bilateral

Figure 10 - Classification of seams by the number of layers and passes:

I-IV - the number of layers; 1 ~ 8 - the number of passes

During welding, each layer of a multilayer seam is annealed during the application of a subsequent layer. As a result of such thermal effects on the weld metal, its structure and mechanical properties are improved. The thickness of each layer in multilayer joints is approximately equal to 5-6 mm.

According to the effective force, the seams are divided into longitudinal (flank), transverse (frontal), combined, oblique (Figure 11). The frontal suture is perpendicular to the force P, the flank is parallel, and the oblique is at an angle.

By position in space, lower, horizontal, vertical and ceiling seams are distinguished (Figure 12). They differ from each other by the angles at which the surface of the part to be welded relative to the horizontal is located. The ceiling seam is the most difficult to perform; the seam is best formed in the lower position. Ceiling, vertical and horizontal seams usually have to be performed in the manufacture and, especially during the installation of large structures.

a) - longitudinal (flank); b) - transverse (frontal);

c) - combined; d) - oblique

Figure 11 - Classification of joints by effective force

Figure 12 - Classification of welds by their position

in space

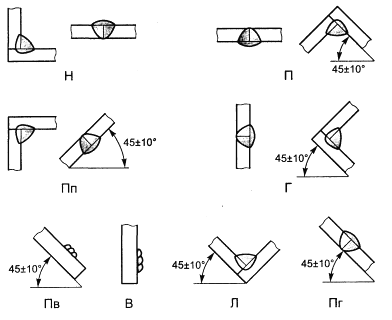

Examples of designation of welds according to their position in space are given in Figure 13.

H - lower; P - ceiling; PP - semi-ceiling; G - horizontal;

Pv - semi-vertical; B - vertical; L - into the boat;

PG - semi-horizontal

Figure 13 - Designation of welds by their position

The effectiveness and quality of work depends on the availability of the necessary tools, materials and skills. Success in any business, no matter what direction it is, is also significantly affected by knowledge of the theory. It is considered one of the most common.

This type of activity requires material, equipment, work experience, as well as theoretical knowledge. Having mastered the necessary information, a person gets an idea of \u200b\u200bwhat a seam is, what kind of classification of welds exists and how to choose the best option for adhesion of various metal products.

What is a weld?

During welding, three metal sections are involved in the process: two pieces of iron are fastened together with the help of a third, which acts as an electrode. At the junction of metal parts with each other, a thermal process occurs, forming a seam. Thus, the seam is a part obtained as a result of exposure to fused and hardened iron.

Any metals can be joined by welding. They have their own structural features, according to which a certain type of fastening is selected. The classification is made depending on the type of adhesion, material and other parameters. Each connection has its own instructions and its own execution order.

Dimensions

There is a classification of welds by length. Depending on the size, there are:

- Short. The size does not exceed 30 cm. Such a seam appears as a result of welding performed in one direction from the very beginning to the end.

- Medium. The seam length is from 30 cm to 1 meter. These seams are welded from the middle to the edges. The reverse step method is ideal for them. Its essence lies in the fact that the entire seam is divided into several sections, which are alternately processed by welding. Each of these segments has a length of 10 to 30 cm.

- Long (over one meter). They are welded in the same way as the middle seams, with the only difference being that the number of sections here will be greater.

Types of welded joints

Classification of welds is also carried out according to the type of fastening. There are four types of compounds:

- butt;

- t-shaped;

- overlap;

- angular.

Most common type

During butt adhesion, the thickness of the product is taken into account. This saves a significant part of the material.

Butt grip is considered the most popular. This is due to the fact that this welding process is the fastest and most economical.

This type of clutch is characterized by a T-shaped connection of metal products. As in the butt joint, special attention is paid to the thickness of the metal, depending on which the seams are unilateral and bilateral.

When applying this type of clutch, it is necessary to adhere to the following recommendations:

- Performing T-welding in the adhesion of two products having different thicknesses, it is necessary to keep the welding torch in relation to the product thicker at an angle of 60 degrees.

- Welding work can be facilitated by placing the structure in the boat. This position of the workpiece will exclude undercuts, missing undercooked areas, which are considered the most common defects for this type of clutch.

- If one pass of the welding torch is ineffective, because defective areas may remain, they should be cooked by oscillating the welding electrodes.

- In T-joints, one-sided welding can be limited. To do this, use Oineo Tronic Pulse welding equipment, which allows RW cooking.

Lap welding

The principle of this type of connection is the two-sided welding of products whose thickness is not more than 1 cm. This welding is used in cases where it is necessary to prevent moisture from entering the gap between the steel sheets. As a result of such work, two seams are formed. This type of welded joint is considered to be long and not economical, since more materials are required for work.

Corner grip

This type of welding is used to connect metal products in a position perpendicular to each other. Depending on the thickness of the sheets, corner welding is characterized by the presence or absence of beveled edges. If necessary, this is done from the inside of the product.

Weld Shapes

The classification of welds according to the shape of the outer surface defines three types:

- Flat. Effective under dynamic and alternating loads, since these seams (as well as concave ones) do not have a stress concentration that can cause sudden changes and destroy the welding adhesion.

- Concave. The concavity of the seam not exceeding 0.3 cm is considered acceptable. Otherwise, the concavity of the weld is considered excessive and is regarded as a defect. The concavity level is measured in the area where there is the greatest deflection.

- Convex seams. They arise as a result of the accumulation of a large amount of solidified metal and are considered uneconomical. But at the same time, a welded joint giving a convex seam is more effective under static load than a joint with a flat or concave welded seam. The bulge is the distance from the surface of the base metal to the point of greatest protrusion. Convexities not exceeding 0.2 cm for lower welding and not more than 0.3 cm for welding performed in other positions are considered standard.

Classification of welds by position in space

According to the space placement criterion, there are four types of welds, each of which has its own characteristics and recommendations for welding:

- Bottom seams. In the technical aspect are considered the simplest. Welding of the lower seams is carried out on a flat surface in the bottom position. This process is characterized by high efficiency and quality. This is due to more comfortable conditions for the welder. The weight of the molten metal is directed into a horizontal weld pool. It’s easy to keep track of the bottom seams. Work is fast.

- Horizontal seams. Weld a little harder. The problem is that the melted metal flows under the influence of its weight on the lower edges. This may result in undercutting at the top edge.

- Vertical seams. They are the result of joints of metal products placed in a vertical plane.

- Ceiling seams. This welding is considered the most difficult and responsible. It is characterized by minimal comfort. The welding process makes it difficult to emit slag and gases. Not everyone can cope with this matter, a lot of experience is needed, since it is not easy to keep the slag falling on the face during work. It is important to observe the quality and strength of the connection.

How are welds and joints labeled?

Classification and designation of welds is carried out using special icons, lines and leaders. They are placed on and on the structure itself. The classification of welded joints and seams is indicated, according to the regulatory document, using special lines, which can be solid or dashed. Continuous denotes visible welds, dashes - invisible.

Symbols of the seam are placed on the shelf from the leader (if the seam is located on the front side). Or, conversely, under a shelf if the seam is placed on the back. Using the icons, the classification of the welds, their intermittence, and the placement of segments for welding are indicated.

Next to the main icons are additional. They contain supporting information:

- on removing the reinforcement of the weld;

- on surface treatment for a smooth transition to the base metal and to prevent sagging and bumps;

- about the line along which the seam is made (whether it is closed).

For identical designs and products of one GOST standard symbols and technical requirements are provided. If the design has the same seams, then it is better for them to give serial numbers and divide them into groups, which are also assigned numbers for convenience. All information on the number of groups and seams should be indicated in the regulatory document.

Seam position

Welds are classified based on the position of the weld. They are:

- One sided. They are formed as a result of welding sheets, the thickness of which does not exceed 0.4 cm.

- Bilateral. They arise during the double-sided welding of metal sheets with a thickness of 0.8 cm. For each connection, it is recommended to leave 2 mm gaps that ensure adhesion quality.

Possible flaws

Defects during welding can occur due to excessively high current and arc voltage. It may also be the result of improper manipulation of the electrodes. Classification of defects of welds at their location:

- Internal To identify them, a technique is used that consists in the control: not destroying the structure, destroying fully or partially.

- Outdoor. They are easily detected by external examination.

Due to a violation of the welding mode caused by a lack of necessary experience, insufficient preparatory work, incorrect measurements, defects are divided into:

- Lack of penetration. It manifests itself in the local absence of fusion between the connected elements. The defect leads to an increase in stress concentration and a decrease in the cross-section of the seam. A design with such a flaw is characterized by reduced strength and reliability. The cause of lack of penetration can be both insufficient current strength and fast welding.

- Undercut. The defect is a local decrease in the thickness of the base metal. This problem is observed near the boundaries of the welds.

- Burn through. The defect has the appearance of a cavity in the weld. It occurs due to leakage of molten metal from the weld pool. Burn-through is an unacceptable defect, it needs to be urgently fixed.

- An undigested crater or indentation. It occurs due to arc breaks during the approach to the end of the seam.

- The influx. The defect is manifested in the flow of weld metal onto the base metal without fusion.

The causes of defects can be very different, but they are equally able to reduce the adhesion strength, operational reliability, accuracy and spoil the appearance of the product.