Gas pressure regulators RDG-25-N (V); RDG-50-N (B); RDG-80-N (B); RDG-150-N (B)

The hydraulic mode of the gas distribution system is controlled by gas pressure regulators (RDGs), which automatically maintain a constant pressure at the point of pulse extraction regardless of the gas consumption intensity. When regulating the pressure, the initial higher pressure decreases to the final lower one. This is achieved by automatically changing the degree of opening of the throttle body of the regulator, as a result of which the hydraulic resistance to the passing gas flow automatically changes.

Depending on the supported pressure (location of the controlled point in the gas pipeline), gas pressure regulators (RDGs) are divided into gas pressure regulators before and after themselves. In hydraulic fracturing (GRU), only gas pressure regulators after themselves are used.

The automatic gas pressure regulator (RDG) consists of an actuator and a regulatory body. The main part of the actuator is a sensing element that compares the signals of the setter and the current value of the adjustable pressure. The actuator converts the command signal into a regulatory action and into the corresponding movement of the moving part of the regulatory body due to the energy of the working medium (this can be the energy of the gas passing through the gas pressure regulator (RDG), or the energy of the medium from an external source of electric, compressed air, hydraulic) .

If the permutation force developed by the sensitive element of the gas pressure regulator is large enough, then it itself carries out the control functions of the regulatory body. Such gas pressure regulators (RDGs) are called direct-acting pressure regulators. To achieve the necessary accuracy of regulation and increase the switching force between the sensing element and the regulatory body, an amplifier command device (sometimes called a pilot) can be installed. The meter controls the amplifier, in which due to extraneous exposure (energy of the working medium), a force is transmitted that is transmitted to the regulatory body.

Since gas throttling occurs in the regulatory bodies of pressure regulators, they are sometimes called throttling ones.

Due to the fact that the gas pressure regulator is designed to maintain a constant pressure at a given point in the gas network, it is always necessary to consider the automatic control system as a whole “regulator and regulation object (gas network)”. The principle of operation of gas pressure regulators (RDG) is based on the regulation of the deviation of the regulated pressure. The difference between the required and actual values \u200b\u200bof the controlled pressure is called the mismatch. It can arise due to various excitations either in the gas network due to the difference between the gas inflow into it and the gas extraction, or due to a change in the gas pressure (up to the regulator).

The correct selection of the gas pressure regulator should ensure the stability of the regulator-gas network system, i.e., its ability to return to its original state after the end of the disturbance.

RDG gas pressure regulators with conditional pass Du-50, Du-80, Du-150 are further referred to as regulators providing reduction of high or medium pressure, automatic maintenance of the outlet pressure at a given level, regardless of changes in flow and inlet pressure, automatic shutdown of gas supply when emergency increase or decrease of the output pressure in excess of the permissible set values. Designed for the installation of hydraulic fracturing and GRU gas supply systems of cities and towns.

The operating conditions of the regulators must correspond to the climatic use of UHL4 in accordance with GOST 15150-69 for operation at ambient temperature from + 1 ° С to + 40 ° С.

The regulator complies with the requirements of GOST 12.2.007.0-7; GOST 11881-76 and during operation does not have a negative impact on the environment.

The regulator is manufactured in two versions:

With output low pressure (N)

With output high pressure (V)

Designators of the regulators when ordering in other documents:

Gas pressure regulator RDG-50N - TU 3700-003-137517595-2004

Gas pressure regulator RDG-50V - TU 3700-003-137517595-2004

Gas pressure regulator RDG-80N - TU 3700-003-137517595-2004

Gas pressure regulator RDG-80V - TU 3700-003-137517595-2004

Gas pressure regulator RDG-150N - TU 3700-003-137517595-2004

Gas pressure regulator RDG-150V - TU 3700-003-137517595-2004

If necessary, indicate the diameter of the seat, then the entry when ordering is as follows:

Gas pressure regulator RDG-50N TU 3700-003-137517595-2004 saddle 35.

Gas pressure regulator RDG-50V TU 3700-003-137517595-2004 saddle35.

Technical characteristics of RDG regulators

|

Parameter |

||||||

|

Adjustable environment |

natural gas according to GOST 5542-87 |

|||||

|

Inlet pressure range, MPa |

||||||

|

Range of adjustment of output pressure, kPa |

||||||

|

Maximum throughput, m³ / h, not less |

||||||

|

The unevenness of regulation,% |

||||||

|

Response pressure of the control mechanism, MPa: |

||||||

|

at lower outlet pressure |

(0.15-0.5) Ryev |

|||||

|

with increasing output pressure |

(1.25-1.5) Ryev |

|||||

|

at Рвых \u003d 0.003 MPa |

||||||

|

Diameter of a saddle, mm |

||||||

|

The diameter of the connecting pipe inlet and outlet, mm |

||||||

|

Compound |

flange in accordance with GOST 12820-80 |

|||||

|

Overall dimensions, mm |

||||||

|

Construction length mm |

||||||

|

Weight kg |

||||||

|

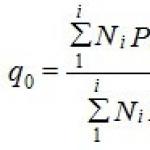

RDG Bandwidth Table |

||||||||||||

|

RDG-50N (30mm saddle) |

RDG-50V (30mm saddle) |

RDG-50N (35mm saddle) |

RDG-50V (35mm saddle) |

RDG-50N (40mm saddle) |

RDG-50V (40mm saddle) |

RDG-50N (45mm saddle) |

RDG-50V (45mm saddle) |

RDG-80N (65mm saddle) |

RDG-80V (65mm saddle) |

RDG-150N (98mm saddle) |

RDG-150V (98mm saddle) |

|

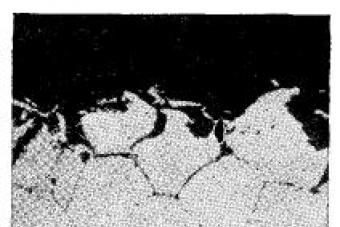

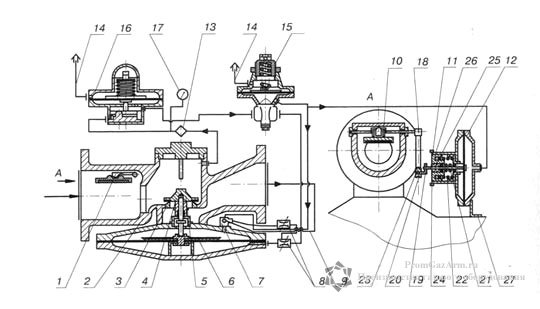

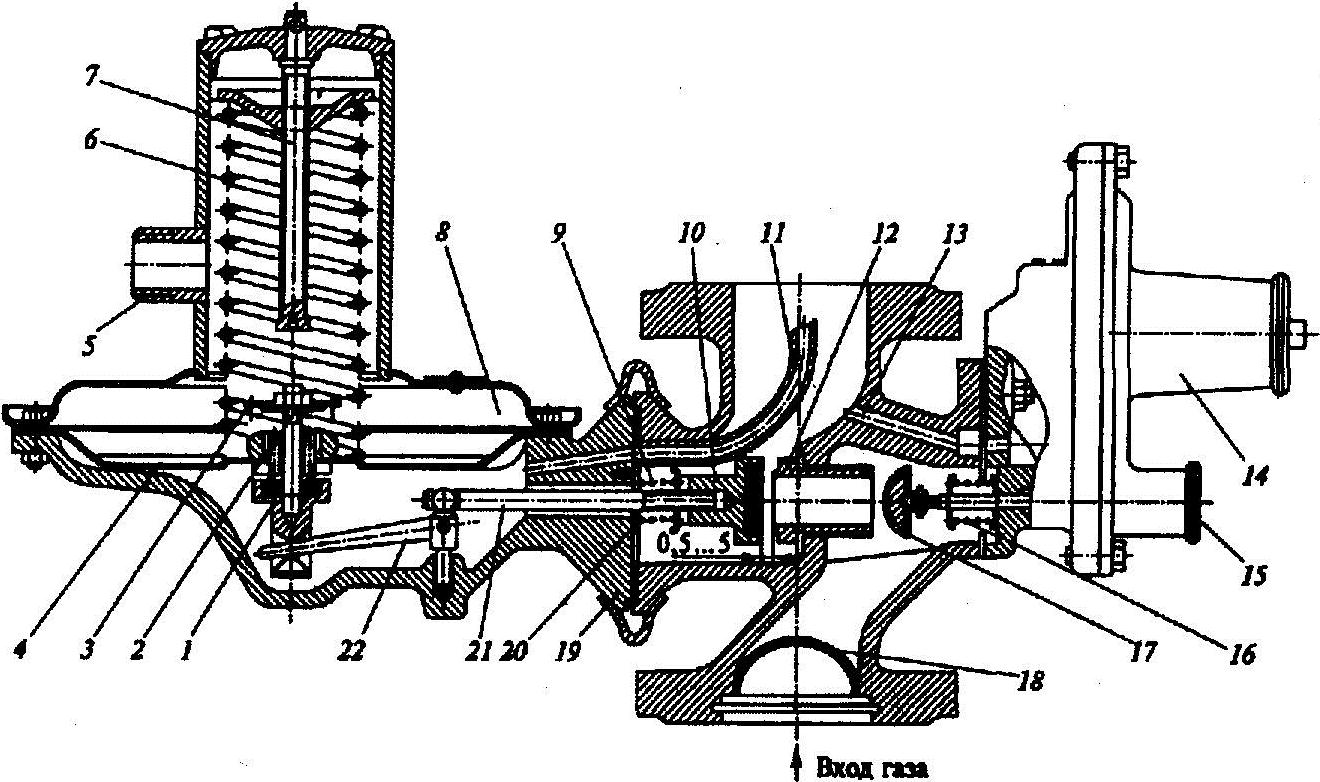

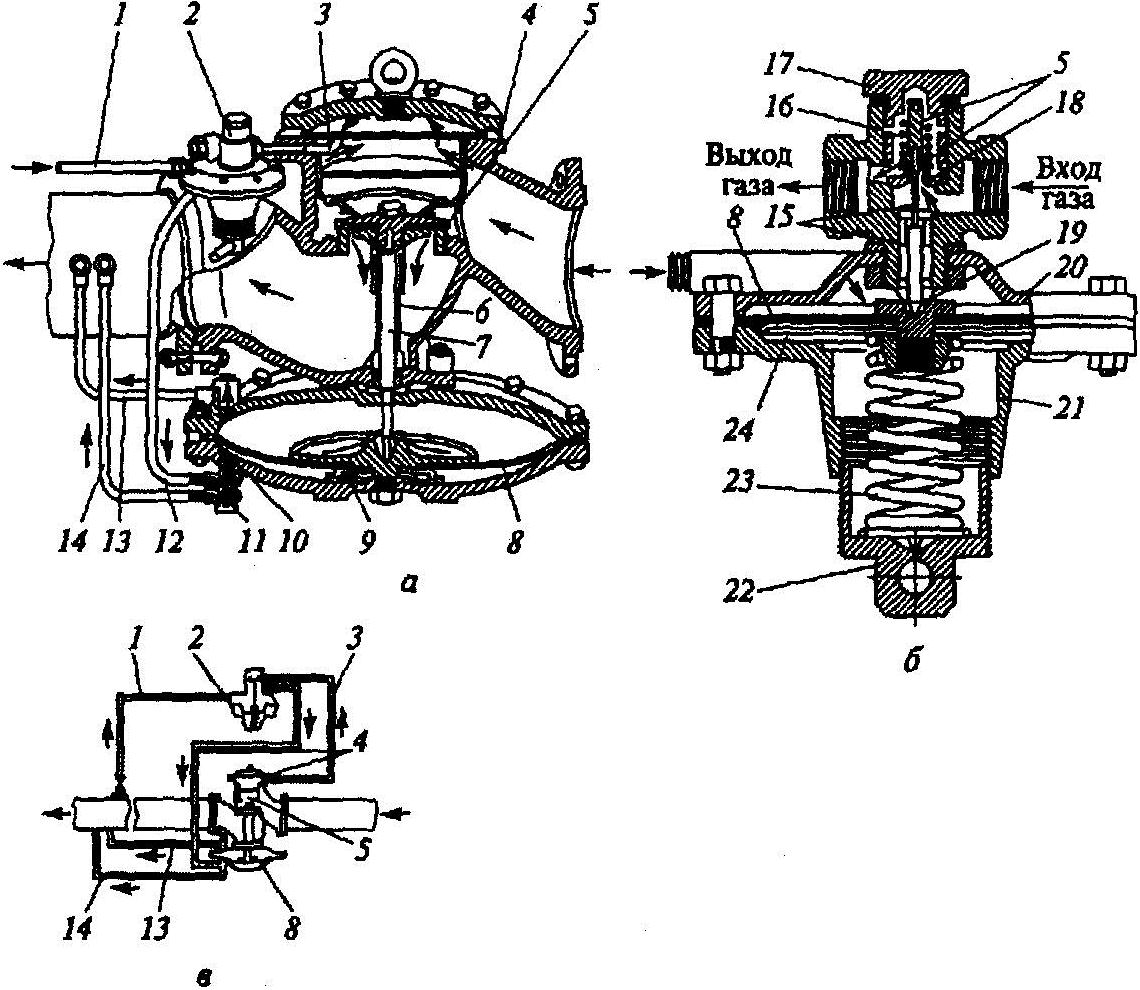

The RDG gas pressure regulator is manufactured in two versions: RDG-V (Fig. 2) consists of an actuator 2, a control regulator 15 and a control mechanism 12. RDG-N (Fig. 1) consists of an actuator 2, a stabilizer 16, and a control regulator 15 and control mechanism 12. The principle of operation is considered on the example of the regulator RDG-N. Actuator 2 has a cast housing, inside of which a seat 3, a membrane actuator and a valve 4 are installed. The membrane actuator consists of a membrane 6, a rod 5 rigidly connected to it, at the end of which a valve 4 is fixed. The rod 5 moves in the bushings of the housing guide column. The actuator is designed by changing the flow area between the valve 4 and the seat 3 to automatically maintain a given output pressure at all gas flow modes, including zero. The stabilizer 16 is designed to maintain constant pressure at the inlet to the control regulator, that is, to eliminate the influence of fluctuations in the input pressure on the operation of the regulator as a whole, and is installed only on the low pressure regulators RDG-N. The pressure on the pressure gauge after the stabilizer should be at least 0.2 MPa (to ensure a stable flow rate). The stabilizer is made in the form of a direct-acting regulator and includes a housing, a membrane unit with a spring load, and a service valve. The control regulator 15 generates control pressure for the submembrane cavity of the actuator in order to reposition the control valve. The control regulator includes a head and a membrane chamber. The head has an inlet and an outlet. The upper chamber has a threaded hole for supplying an output pressure pulse. A higher spring, a support washer and a lower cover with a smaller working area are installed in the high pressure control regulator.

Adjustable chokes 8 in the submembrane cavity of the actuator and on the discharge pulse tube are used to configure for quiet (without self-oscillations) operation of the regulator.

Adjustable throttles 8 (Fig. 3) include a throttle 28, a nozzle 29 with a slot and a bolt 30. The pressure gauge is designed to continuously monitor the output pressure and provide a signal to operate the shut-off valve in the actuator in case of emergency increase or decrease in the output pressure over the permissible set values. The control mechanism consists of a detachable housing, a membrane, a rod, a control mechanism 11, large and small springs, balancing the action of the output pressure pulse on the membrane.

The filter 13 is designed to purify the gas supplying the stabilizer and control regulator from mechanical impurities. The regulator works as follows: the inlet pressure gas enters through the filter to the stabilizer 16, then to the control regulator 15. From the control regulator (for RDG-N) the gas through the adjustable throttle 8 enters the submembrane cavity, the submembrane cavity of the actuator is connected by an impulse tube 9 to the output regulator. Through the inductor 8 and the impulse tube 9, the submembrane cavity of the actuator is connected to the gas pipeline and the regulator. The pressure in it during operation will sometimes be greater than the outlet pressure. The supmembrane cavity of the actuator is under the influence of the outlet pressure. The control regulator maintains a constant pressure, so the pressure in the submembrane cavity will also be constant (in steady state).

Any deviations of the outlet pressure from the predetermined one cause changes in the pressure in the supmembrane cavity of the actuator, which leads to the movement of the valve 4 to a new equilibrium state corresponding to the new values \u200b\u200bof the inlet pressure and flow rate, while the outlet pressure is restored. In the absence of gas flow, the valve 4 is closed, since there is no control pressure drop between the supmembrane and submembrane cavities of the actuator. In the presence of minimal gas consumption, a control pressure drop is formed in the supmembrane and submembrane cavities of the actuator, as a result of which the membrane 6 with the rod 5 rigidly connected to it, at the end of which the valve 4 is fixed, will move and open the gas passage through the gap between the valve seal and saddle.

With a decrease in gas flow, the valve under the action of the modified control differential pressure in the cavities of the actuator will reduce the passage of gas through the decreasing gap between the valve seal and the seat and then block the seat. In the event of an emergency increase or decrease in the outlet pressure, the membrane of the control mechanism 12 moves to the left or right, the shut-off valve lever leaves contact with the rod 11 of the control mechanism, the shut-off valve, by the action of the spring 10, shuts off the gas flow to the regulator. In order to prevent gas from entering the room where the regulator is installed, in case of a breakdown of the stabilizer membrane or control regulator, an organized discharge into the atmosphere through fittings (M14ґ1) in the stabilizer and control regulator covers should be provided. Regulators are mounted on a horizontal section of the gas pipeline with the membrane chamber down. The distance from the lower chamber to the floor and the gap between the membrane chamber and the wall when installing the regulator in hydraulic fracturing and GRU must be at least 300 mm. The pulse pipeline connecting the regulator to the sampling point should have a diameter: Du25 for RDG-50, Du32 for RDG-80 and RDG-150.

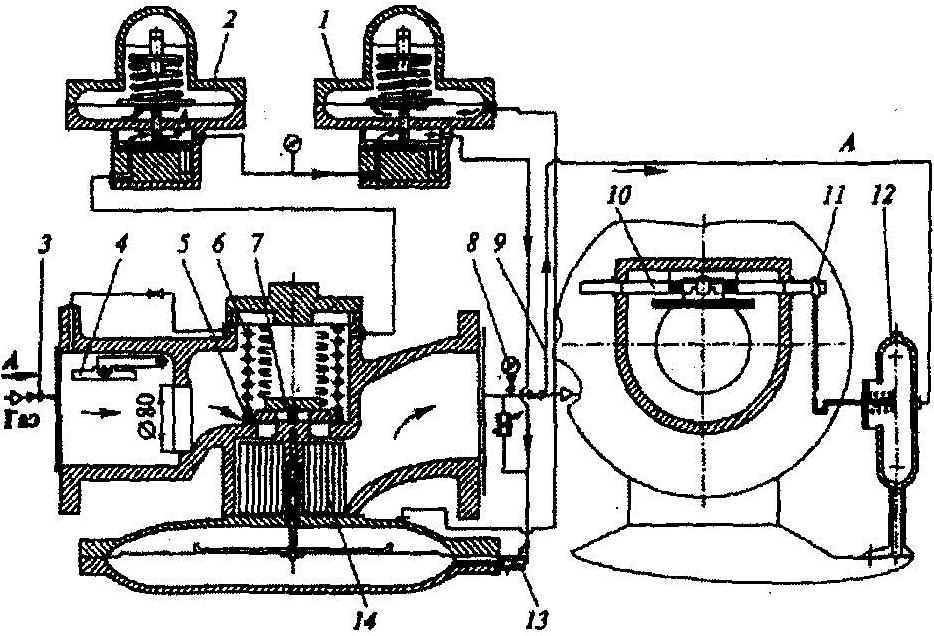

Figure 1. RDG-N gas pressure regulator:

1 - shut-off valve; 2 - executive device; 3 - a saddle; 4 - working valve; 5 - a core; 6 - membrane actuator; 7 - throttle washer; 8 - adjustable chokes; 9 - impulse tube of the inlet gas pipeline; 10 - spring shut-off valve; 11 - rod control mechanism; 12 - control mechanism; 13 - filter; 14 - a candle; 15 - control regulator; 16 - stabilizer; 17 - manometer; 18 - lever shut-off valve; 19 - an arm; 20 - screw; 21 - a small spring; 22 - a large spring; 23 - a bracket; 24 - bracket; 25 - reg. small spring screw; 26 - reg. large spring screw; 27 - bracket

Figure 2. RDG-V gas pressure regulator:

1 - shut-off valve; 2 - executive device; 3 - a saddle; 4 - working valve; 5 - a core; 6 - membrane actuator; 7 - throttle washer; 8 - adjustable chokes; 9 - impulse tube of the inlet gas pipeline; 10 - spring shut-off valve; 11 - rod control mechanism; 12 - control mechanism; 13 - filter; 14 - a candle; 15 - control regulator; 18 - lever shut-off valve; 21 - a small spring; 22 - a large spring; 23 - a bracket; 25 - reg. small spring screw; 26 - reg. large spring screw; 27 - bracket

Figure 3:

28 - throttle; 29 - fitting; 30 - bolts

Order RDG-25-N (V), RDG-50-N (V) gas pressure regulator, RDG-80-N (V), RDG-150-N (V), delivery times are available by using or. Upon request, we will provide: a scheme, passport, certificate, permission.

Classification. Gas pressure regulators classify:by purpose, the nature of the regulatory action, the relationship between the input and output quantities, the method of exposure to the control valve.

By the nature of the regulatory impact, regulators are divided into astatic and static (proportional). Schematic diagrams of the regulators are shown in the figure below.

Pressure Regulator Diagram

a - astatic: 1 - rod; 2 - membrane; 3 - cargo; 4 - a submembrane cavity; 5 - gas outlet; 6 - valve; b - static: 1 - rod; 2 - spring; 3 - membrane; 4 - a submembrane cavity; 5 - impulse tube; 6 - an epiploon; 7 - valve.

IN astatic regulator membrane has a piston shape, and its active area, perceiving gas pressure, practically does not change at any position of the control valve. Therefore, if the gas pressure balances the gravity of the membrane, stem and valve, then the membrane suspension corresponds to the state of astatic (indifferent) equilibrium. The process of regulating gas pressure will proceed as follows. Suppose that the gas flow through the regulator is equal to its inflow and the valveoccupies a certain position. If the gas flow increases, the pressure decreasesand the membrane device will lower, which will lead to an additional opening of the control valve. After the restoration of the equality between inflow and flow, the gas pressure will increase to a predetermined value. If the gas flow rate decreases and a corresponding increase in gas pressure occurs, the regulation process will proceed in the opposite direction. Adjust the regulator to the required gas pressure using special weights, moreover, with an increase in their mass, the outlet gas pressure increases.

After perturbation, astatic regulators bring the regulated pressure to a predetermined value regardless of the load and the position of the control valve. The equilibrium of the system is possible only with a given value of the adjustable parameter, while the control valve can occupy any position. Astatic regulators are often replaced by proportional ones.

In static (proportional) controllers, unlike astatic ones, the submembrane cavity is separated from the collector by an oil seal and connected to it by a pulse tube, i.e., feedback nodes are located outside the object. Instead of weights, a spring compressive force acts on the membrane.

In an astatic controller, the slightest change in the gas outlet pressure can lead to a movement of the control valve from one extreme position to another, and in a static valve, a complete movement of the valve occurs only with the corresponding compression of the spring.

Both astatic and proportional controllers, when working with very narrow proportional limits, have the properties of systems operating on the principle of “open-closed”, that is, with a slight change in the gas parameter, the valve moves instantly. To eliminate this phenomenon, install special chokes in the fitting connecting the working cavity of the membrane device with a gas pipeline or a candle. Installing throttles allows you to reduce the speed of movement of the valves and achieve more stable operation of the regulator.

According to the method of acting on the control valve, direct and indirect controllers are distinguished. In regulators direct action the control valve is directly or through dependent parameters under the action of the control parameter, and when the value of the controlled parameter changes, it is actuated by the force arising in the sensitive element of the controller, sufficient to move the control valve without an extraneous energy source.

In regulators indirect action the sensing element acts on the control valve by an external source of energy (compressed air, water or electric current).

When the magnitude of the control parameter changes, the force arising in the sensitive element of the regulator activates an auxiliary device that opens up the access of energy from an extraneous source to the mechanism that moves the control valve.

Direct pressure regulators are less sensitive than indirect pressure regulators. The relatively simple design and high reliability of direct-acting pressure regulators have led to their widespread use in the gas industry.

Throttle devices pressure regulators (figure below) - valves of various designs. Gas pressure regulators use single-seat and two-seat valves. Single-seat valves are affected by a one-way force equal to the product of the area of \u200b\u200bthe seat bore and the pressure difference on both sides of the valve. The presence of effort only on the one hand complicates the control process and at the same time increases the effect of pressure changes up to the regulator on the outlet pressure. At the same time, these valves provide reliable shutdown of gas in the absence of its selection, which led to their widespread use in the designs of the regulators used in hydraulic fracturing.

Throttle devices for gas pressure regulators

a - single-seat rigid valve; b - soft single-seat valve; c - cylindrical valve with a window for gas passage; d - rigid double-seat valve continuous with guide feathers; d - soft two-seat valve

Two-seat valves do not provide a tight seal. This is explained by the uneven wear of the seats, the difficulty of grinding the shutter at the same time for two saddles, and also due to the fact that the shutter and saddle dimensions do not vary equally with temperature fluctuations.

The capacity of the regulator depends on the size of the valve and the size of its stroke. Therefore, the regulators are selected depending on the maximum possible gas consumption, as well as the size of the valve and the size of its stroke. Regulators installed in hydraulic fracturing should operate in the load range from 0 ("per impasse") to the maximum.

The capacity of the regulator depends on the ratio of pressures before and after the regulator, gas density and final pressure. In the manuals and reference books there are tables of regulator capacity with a differential pressure of 0.01 MPa. To determine the throughput of the regulators with other parameters, a recount is necessary.

Membranes Using membranes, the energy of gas pressure is converted into mechanical energy of motion transmitted through a system of levers to the valve. The choice of membrane design depends on the purpose of the pressure regulators. In astatic regulators, the constancy of the working surface of the membrane is achieved by giving it a piston shape and the use of crimp bend limiters.

The greatest application in the design of regulators found ring membranes (figure below). Their use facilitated the replacement of membranes during repair work and made it possible to unify the main measuring devices of various types of regulators.

Annular membrane

a - with one disk: 1 - disk; 2 - corrugation; b - with two disks

The movement of the membrane device up and down occurs due to the deformation of the flat corrugation formed by the support disk. If the membrane is in its lowest position, then the active area of \u200b\u200bthe membrane is its entire surface. If the membrane moves to its highest position, then its active area decreases to the disk area. With a decrease in the diameter of the disk, the difference between the maximum and minimum active area will increase. Therefore, to raise the annular membranes, a gradual increase in pressure is necessary to compensate for the decrease in the active area of \u200b\u200bthe membrane. If the membrane during operation is subjected to alternating pressure on both sides, put two discs - on top and bottom.

For low output pressure regulators, the one-way gas pressure on the membrane is balanced by springs or weights. For high or medium output pressure regulators, gas is supplied to both sides of the membrane, relieving it from unilateral forces.

Regulators of direct action are divided into pilot and unmanned. Pilot Regulators (RSD, RDUK and RDV) have a control device in the form of a small regulator called a pilot.

Unmanned controllers (RD, RDK and RDG) do not have a control device and differ from the pilot dimensions and throughput.

Direct pressure gas pressure regulators. Regulators RD-32M and RD-50M are unmanned, direct-acting, differ in nominal diameters of 32 and 50 mm and provide gas supply up to 200 and 750 m 3 / h, respectively. The RD-32M regulator case (figure below) is connected to the gas pipeline with union nuts. Reducing gas is supplied via a pulse tube to the submembrane space of the regulator and exerts pressure on the elastic membrane. A spring back pressure exerts on the membrane. If the gas flow rate increases, then its pressure behind the regulator will decrease, the gas pressure in the sub-membrane space of the regulator will decrease accordingly, the equilibrium of the membrane will be disturbed, and it will move down under the action of the spring. By moving the diaphragm down, the lever mechanism will move the piston away from the valve. The distance between the valve and the piston will increase, this will lead to an increase in gas flow and restoration of the final pressure. If the gas flow rate after the regulator decreases, then the outlet pressure will increase, and the regulation process will occur in the opposite direction. Replaceable valves allow you to change the capacity of the regulators. Regulators are adjusted to a predetermined pressure mode using an adjustable spring, nut and adjusting screw.

Pressure regulator RD-32M

1 - membrane; 2 - adjustable spring; 3,5 - nuts; 4 - adjusting screw; 6 - cork; 7 - nipple; 8, 12 - valves; 9 - a piston; 10 - impulse tube of the final pressure; 11 - lever mechanism; 12 - safety valve

During low gas hours, the gas outlet pressure may increase and cause rupture of the regulator diaphragm. A special device, a safety valve built into the central part of the membrane, protects the membrane from rupture. The valve provides gas discharge from the submembrane space into the atmosphere.

Combined regulators. The domestic industry produces several varieties of such regulators: RDNK-400, RDGD-20, RDSK-50, RGD-80. These regulators got this name because the relief and shut-off (shut-off) valves are mounted in the regulator body. The figures below show the schemes of combined controllers.

Regulator rdnk-400. RDNK-type regulators are available in the following modifications: RDNK-400, RDNK-400M, RDNK-1000 and RDNK-U.

Gas pressure regulator RDNK-400

1 - relief valve; 2, 20 - nuts; 3 - spring adjustment valve; 4 - working membrane; 5 - fitting; 6 - spring setting the output pressure; 7 - adjusting screw; 8 - membrane chamber; 9, 16 - springs; 10 - working valve; 11, 13 - pulsed tubes; 12 - nozzle; 14 - disconnecting device; 15 - a glass; 17 - shut-off valve; 18 - filter; 19 - case; 21, 22 - lever mechanism

The device and the principle of operation of the regulators is shown on the example of RDNK-400 (figure above). The combined low-pressure regulator consists of a pressure regulator and an automatic disconnecting device. The regulator has a built-in impulse tube included in the submembrane cavity, and a pulse tube. The nozzle located in the regulator body is simultaneously the seat of the working and shut-off valves. The working valve by means of a lever mechanism (stem and lever) is connected to the working membrane. Replaceable spring and adjusting screw are used to adjust the gas outlet pressure.

The disconnecting device has a membrane connected to the actuator, the latch of which holds the shut-off valve in the open position. The setting of the disconnecting device is carried out by interchangeable springs located in the glass.

Medium or high pressure gas supplied to the regulator passes through the gap between the service valve and the seat, reduces to low pressure and flows to consumers. The pulse from the outlet pressure through the pipeline enters from the outlet pipeline into the submembrane cavity of the regulator and to the disconnecting device. If the output pressure rises or falls above predetermined parameters, the latch located in the disconnecting device is disengaged by the force on the membrane of the disconnecting device, the valve closes the nozzle, and gas flow stops. The regulator is put into operation manually after eliminating the causes that caused the trip of the disconnecting device. The technical characteristics of the controller are shown in the table below.

Technical characteristics of the regulator RDNK-400

The manufacturer supplies a regulator configured for an outlet pressure of 2 kPa, with the appropriate settings for the relief and shut-off valves. The outlet pressure is regulated by rotating the screw. When rotating clockwise, the output pressure increases, against - decreases. The relief valve is adjusted by rotating the nut, which loosens or compresses the spring.

RDSK-50 regulator. An independent working pressure regulator, an automatic shut-off device, a relief valve, a filter (figure below) are arranged in a regulator with an output medium pressure. The technical characteristics of the regulator are given in the table below.

RDSK-50 gas pressure regulator

1 - shut-off valve; 2 - valve seat; 3 - case; 4, 20 - membrane; 5 - cover; 6 - a nut; 7 - fitting; 8, 12, 21, 22, 25, 30 - springs; 9, 23, 24 - guides; 10 - a glass; 11, 15, 26, 28 - stocks; 13 - waste valve; 14 - unloading membrane; 16 - a saddle of a working valve; 17 - working valve; 18, 29 — impulse tubes; 19 - a pusher; 27 - cork; 31 - regulator body; 32 - mesh filter

The output pressure is adjusted by rotating the guide. When rotating clockwise, the output pressure increases, against - decreases. The response pressure of the relief valve is controlled by rotating the nut.

The disconnecting device is adjusted by lowering the output pressure by compressing or loosening the spring, rotating the guide, and also increasing the output pressure by compressing or loosening the spring, rotating the guide.

Starting the regulator after eliminating the malfunctions that caused the tripping of the disconnecting device, turn the plug out, as a result of which the valve moves down until the stem moves to the left under the action of the spring and moves over the protrusion of the valve stem, thus holding it in the open position. After this, screw the stopper all the way.

Controller SpecificationsRDSK-50

|

Maximum inlet pressure, MPa, no more |

|

|

The limits of the output pressure, MPa |

|

|

Throughput at an inlet pressure of 0.3 MPa, m 3 / h, not more than |

|

|

Oscillation of the outlet pressure without adjustment of the regulator when the gas flow rate and inlet pressure fluctuations by ± 25%, MPa, not more than |

|

|

The upper limit of the pressure setting of the onset of operation of the relief valve, MPa |

|

|

Upper and lower limits for setting the response pressure of the automatic disconnecting device, MPa: with increasing output pressure more with decreasing output pressure less |

|

|

Nominal bore, mm: inlet nozzle of the outlet nozzle |

The manufacturer supplies a regulator tuned to an outlet pressure of 0.05 MPa, with the appropriate setting of the relief valve and shut-off device. When adjusting the output pressure of the regulator, as well as triggering the relief valve and the disconnecting device, the replaceable springs included in the delivery kit are used. The regulator is installed on a horizontal section of the gas pipeline with the glass up.

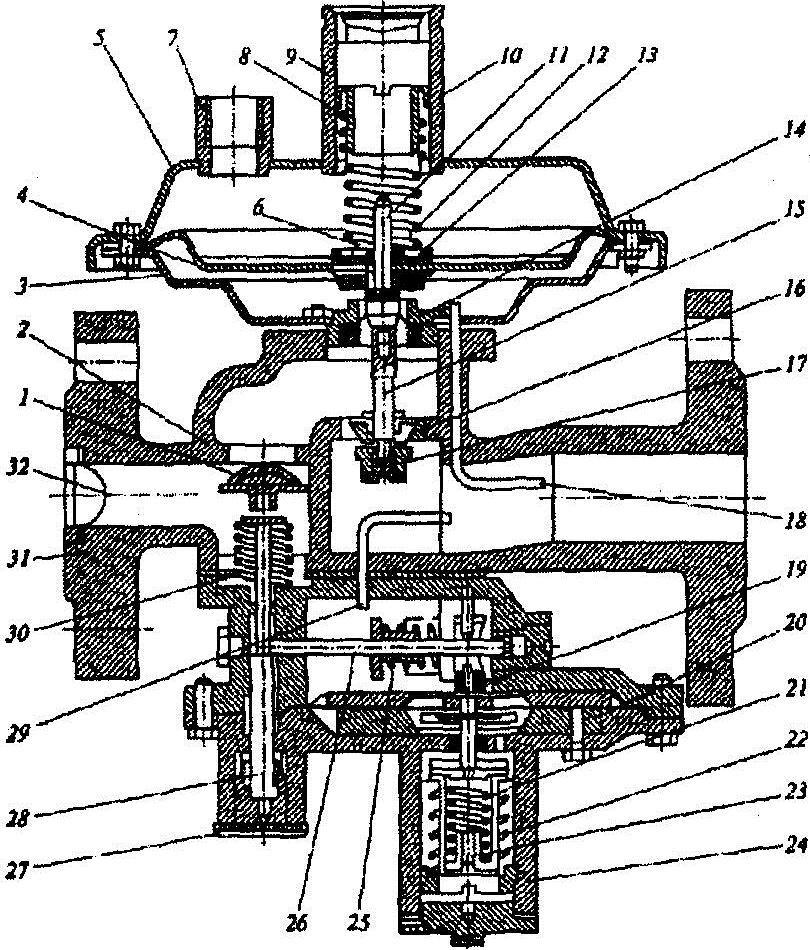

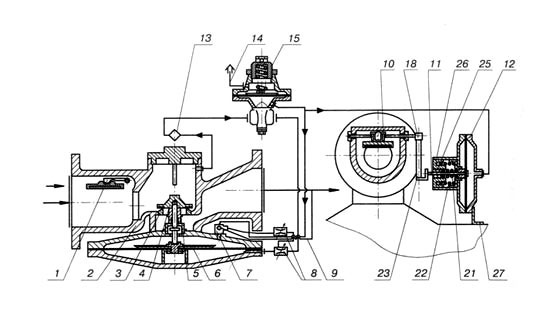

Gas pressure regulator RDG-80 (picture below). Combined regulators of the RDG series for district hydraulic fracturing are produced for nominal passes of 50, 80, 100, 150 mm; they are devoid of a number of disadvantages inherent in other regulators.

RDG-80 regulator

1 - pressure regulator; 2 - pressure stabilizer; 3 - input tap; 4 - shut-off valve; 5 - working large valve; 6 - spring; 7 - working small valve; 8 - pressure gauge; 9 - pulse gas pipeline; 10 - rotary axis of the shut-off valve; 11 - rotary lever; 12 - control mechanism shut-off valve; 13 - an adjustable throttle; 14 - silencer

Each type of regulator is designed to reduce high or medium gas pressures to medium or low, to automatically maintain the outlet pressure at a given level regardless of changes in flow and inlet pressure, and also to automatically turn off the gas supply in case of emergency increase and decrease in outlet pressure in excess of the specified allowable values.

The scope of the RDG controllers is hydraulic fracturing and reduction units of the GRU of industrial, municipal and domestic facilities. Regulators of this type are indirect. The regulator includes: actuator, stabilizer, control regulator (pilot).

The RDG-80 regulator provides stable and precise control of gas pressure from minimum to maximum. This is achieved by the fact that the control valve of the actuator is made in the form of two spring-loaded valves of different diameters, ensuring stability of control over the entire flow range, and in the control regulator (pilot), the operating valve is located on the two-arm lever, the opposite end of which is spring-loaded; The setting force on the lever is superimposed between the lever support and the spring. This ensures the tightness of the working valve and the accuracy of regulation in proportion to the ratio of the lever arms.

The actuator consists of a housing, inside of which a large saddle is installed. The membrane actuator includes a membrane of a rod rigidly connected to it, at the end of which a small valve is fixed; between the protrusion of the stem and the small valve, a large valve is freely located, and the saddle of the small valve is also fixed on the stem. Both valves are spring loaded. The rod moves in the bushings of the guide column of the housing. Under the saddle is a silencer made in the form of a pipe with slotted holes.

The stabilizer is designed to maintain a constant pressure at the inlet to the control regulator, that is, to eliminate the influence of fluctuations in the input pressure on the operation of the regulator as a whole.

The stabilizer is made in the form of a direct-acting regulator and includes a housing, a membrane unit with a spring load, a working valve, which is located on a two-arm lever, the opposite end of which is spring-loaded. With this design, the tightness of the control valve and stabilization of the outlet pressure are achieved.

The control regulator (pilot) changes the control pressure in the supmembrane cavity of the actuator in order to shift the control valves of the actuator in case of a mismatch in the regulation system.

The supravalvated cavity of the impulse tube control regulator is connected via throttling devices to the submembrane cavity of the actuator and to the discharge gas pipeline.

The submembrane cavity is connected by a pulse tube to the supmembrane cavity of the actuator. Using the adjusting screw of the diaphragm spring of the control regulator, the control valve is adjusted to a predetermined output pressure.

Adjustable throttles from the submembrane cavity of the actuator and the discharge impulse tube are used to adjust the regulator for quiet operation. The adjustable throttle includes a housing, a needle with a slot and a plug. The pressure gauge serves to control the pressure after the stabilizer.

The control mechanism consists of a detachable housing, a membrane, a rod of large and small springs, equalizing the impact on the membrane of the output pressure pulse.

The shut-off valve control mechanism provides continuous control of the outlet pressure and the issuance of a signal to activate the shut-off valve in the actuator in case of emergency increase and decrease in the outlet pressure in excess of the specified permissible values.

The bypass valve is designed to balance the pressure in the chambers of the inlet pipe before and after the shut-off valve when it is put into operation.

The regulator operates as follows. To start the regulator into operation, it is necessary to open the bypass valve, the inlet gas pressure enters through the pulse tube into the supravalve space of the actuator. The gas pressure before and after the shut-off valve is equalized. By turning the lever, the shut-off valve is opened. The gas pressure through the saddle of the shut-off valve enters the supravalve space of the actuator and through the pulse gas pipeline to the subvalve space of the stabilizer. Under the action of the spring and gas pressure, the valves of the actuator are closed.

The stabilizer spring is set to a given gas outlet pressure. The inlet gas pressure is reduced to a predetermined value, enters the supravalve space of the stabilizer, into the submembrane space of the stabilizer and through the impulse tube to the subvalve space of the pressure regulator (pilot). The pilot's compression adjustment spring acts on the membrane, the membrane lowers down, acts through the plate on the stem, which moves the beam. The pilot valve opens. From the control regulator (pilot), gas through an adjustable throttle enters the submembrane cavity of the actuator. Through the throttle, the submembrane cavity of the actuator is connected to the gas cavity behind the regulator. The gas pressure in the submembrane cavity of the actuator is greater than in the supmembrane. A membrane with a rod rigidly connected to it, at the end of which a small valve is fixed, will move and open the gas passage through the gap formed between the control of the small valve and the small seat, which is directly installed in the large valve. In this case, the large valve is pressed against the large seat under the action of the spring and the inlet pressure, and therefore the gas flow rate is determined by the passage section of the small valve.

The gas outlet pressure via impulse lines (without throttles) enters the submembrane space of the pressure regulator (pilot), into the submembrane space of the actuator, and onto the membrane of the shut-off valve control mechanism.

If the gas flow increases under the action of the control pressure drop in the cavities of the actuator, the membrane will move further and the rod will open its large valve with its protrusion and increase the gas passage through the additional gap formed between the large valve seal and the large seat.

With a decrease in gas flow, a large valve under the action of a spring and moving away in the opposite direction under the action of the changed control differential pressure in the cavities of the actuator rod with protrusions will reduce the flow area of \u200b\u200bthe large valve and block the large seat; while the small valve remains open, and the regulator will begin to work in low load mode. With a further decrease in gas flow, the small valve under the action of the spring and the control pressure drop in the cavities of the actuator together with the membrane will come into further movement in the opposite direction and reduce the gas flow, and in the absence of gas flow, the small valve will block the seat.

In case of emergency increases or decreases in the outlet pressure, the membrane of the control mechanism moves to the left or right, the shut-off valve stem comes out of contact with the control mechanism stem, the valve blocks the gas inlet to the regulator under the action of a spring.

Gas pressure regulator designed by Kazantsev (RDUK). The domestic industry produces these regulators with nominal diameters of 50, 100 and 200 mm. The characteristics of the RDUK are shown in the table below.

Characteristics of RDUK regulators

|

Throughput at a pressure drop of 10 LLC Pa and a density of 1 kg / m, m 3 / h |

Diameter mm |

Pressure, MPa |

||

|

conditional |

maximum input |

final |

||

RDUK-2 regulator

a - sectional view of the regulator; b - pilot of the regulator; c - regulator binding circuit; 1, 3, 12, 13, 14 - impulse tubes; 2 - control regulator (pilot); 3 - case; 5 - valve; 6 - column; 7 - valve stem; 8 - membrane; 9 - support; 10 - throttle; 11 - fitting; 15 - fitting with a pusher; 16, 23 - springs; 17 - cork; 18 - pilot valve seat; 19 - a nut; 20 - housing cover; 21 - pilot housing; 22 - threaded glass; 24 - disk

The RDUK-2 regulator (see the figure above) consists of the following elements: a control valve with a membrane actuator (actuator); control regulator (pilot); chokes and connecting tubes. The initial pressure gas passes through the filter before entering the control regulator, which improves the working conditions of the pilot.

The pressure regulator membrane is sandwiched between the housing and the membrane box lid, and in the center - between the flat and bowl-shaped discs. The cup-shaped disk rests against the groove of the lid, which ensures centering of the membrane before it is clamped.

A pusher abuts in the middle of the membrane plate socket, and a rod presses on it, which freely moves in the column . A valve spool is freely mounted on the upper end of the stem. The tight closing of the valve seat is ensured by the mass of the spool and the gas pressure on it.

The gas leaving the pilot, through a pulse tube enters under the regulator’s membrane and is partially discharged through the tube into the outlet gas pipeline. To limit this discharge, a throttle with a diameter of 2 mm is installed at the junction of the tube with the gas pipeline, thereby achieving the necessary gas pressure under the regulator membrane with a small gas flow through the pilot. An impulse tube connects the supmembrane cavity of the regulator with the outlet gas pipeline. The supmembrane cavity of the pilot, separated from its outlet fitting, also communicates with the outlet gas line through the impulse tube. If the gas pressure on both sides of the regulator diaphragm is the same, then the regulator valve is closed. The valve can be opened only if the gas pressure under the membrane is sufficient to overcome the gas pressure on the valve from above and to overcome the gravity of the membrane suspension.

The regulator operates as follows. Initial pressure gas from the supravalve chamber of the regulator enters the pilot. Having passed the pilot valve, the gas moves along the impulse tube, passes through the throttle and enters the gas pipeline after the control valve.

The pilot valve, throttle and impulse tubes are a throttle-type amplification device.

The final pressure impulse perceived by the pilot is amplified by the throttle device, transformed into command pressure and transmitted through the tube to the submembrane space of the actuator, moving the control valve.

With a decrease in gas flow, the pressure after the regulator begins to increase. This is transmitted via an impulse tube to the pilot's membrane, which lowers down, closing the pilot's valve. In this case, the gas from the high side through the impulse tube cannot pass through the pilot. Therefore, its pressure under the membrane of the regulator gradually decreases. When the pressure under the membrane is less than the gravity of the plate and the pressure exerted by the regulator valve, as well as the gas pressure on the valve from above, the membrane will go down, displacing gas from under the membrane cavity through a pulse tube to discharge. The valve gradually begins to close, reducing the opening for gas passage. The pressure after the regulator will drop to the set value.

With increasing gas flow, the pressure after the regulator decreases. Pressure is transmitted through a pulse tube to the pilot's membrane. The membrane of the pilot under the action of the spring goes up, opening the pilot valve. Gas from the high side through the impulse pipe enters the pilot valve and then through the impulse pipe goes under the regulator membrane. Part of the gas enters the discharge through a pulse tube, and part - under the membrane. The gas pressure under the regulator membrane increases and, overcoming the mass of the membrane suspension and the gas pressure on the valve, moves the membrane up. The valve of the regulator thus opens, increasing the hole for the passage of gas. The gas pressure after the regulator rises to a predetermined value.

With increasing gas pressure in front of the regulator, it reacts in the same way as in the first case considered. When the gas pressure decreases in front of the regulator, it works the same way as in the second case.

Product Composition

The gas pressure regulator RDG-N includes: an actuator 2, a filter 13, a pressure gauge 17, a stabilizer 16, a control regulator (KN-2) 15, a control mechanism 12, a throttle 8, 8a, in accordance with Figure 1; RDG-V actuator 2, control regulator (KV-2) 15, control mechanism 12, filter 13, throttle 8, 8a in accordance with Figure 2.

Completeness

Table 2.

Notes: The manufacturer supplies the RDG-N and RDG-V regulator with the minimum output pressure set in accordance with paragraph 3 of table 1.

Device and principle of operation

The gas pressure regulator is manufactured in two versions of the RDG-N in accordance with Figure 1 and the RDG-V in accordance with Figure 2.

Actuator 2 automatically maintains a given output pressure at all gas flow rates by changing the gap between valve 4 and seat 3.

Actuator 2 consists of a housing with a saddle and a guide column 3, a membrane with a rigid center 6, pinched around the perimeter between the caps of the upper and lower and connected to the center by a pusher with a rod 5, freely moving in the bushings of the guide column and pushing the valve 4.

The filter 13 is designed to purify the gas used to control the regulator from mechanical impurities entering the regulator from the hydraulic fracturing or GRU system.

The filter 13 consists of two housings, one of which has a fitting for pressure inlet, the second has an outlet for pressure outlet.

A filter element is placed between the housings.

The pressure gauge is designed to control the outlet pressure after the stabilizer or to control the inlet pressure to the control regulator (KN-2).

The stabilizer 16 is designed to maintain a constant pressure at the inlet to the control regulator, i.e. to exclude the effects of fluctuations in the input pressure on the operation of the regulator as a whole, it is installed only on the low-pressure regulator RDG-N in accordance with Figure 1. The pressure on the manometer after the stabilizer should be 0.2 MPa (to ensure the required speed).

The stabilizer 16 is made in the form of a direct-acting regulator and consists of a valve with a seat and a saddle overlap plate with a load spring and a membrane center with a rigid center clamped along the perimeter of two bodies and connected in the center by a pusher with a valve bar.

The control regulators KN-2 and KV-2 generate control pressure for the submembrane cavity of the actuator in order to reposition the control valve.

The control regulator KN-2 in accordance with Figure 1 and KB-2 in accordance with Figure 2 consists of a regulator head with two fittings for inlet and outlet pressure, a membrane chamber with a fitting for supplying an inlet pressure pulse. The membrane unit with a rigid center and spring load is clamped around the perimeter between the housing and the cover and is connected in the center by a pusher with a valve of the head.

In the KN-2 low pressure control regulator, replaceable load springs are installed to ensure the full range of output pressure. The spring KPZ-50-05-06-02TB (? 2.5) provides a Rvykh \u003d 0.0015 ... 0.0030 MPa, the spring RDG-80-05-29-06 (? 4.5) provides a Rvykh \u003d 0 , 0030 ... 0,0600 MPa.

In the KV-2 high pressure control regulator, a stronger spring, a support washer and a cover with a smaller working area are installed.

Adjustable chokes 8 and 8a in the submembrane cavity of the actuator and on the impulse tube are used to configure the regulator to operate quietly (without self-oscillations).

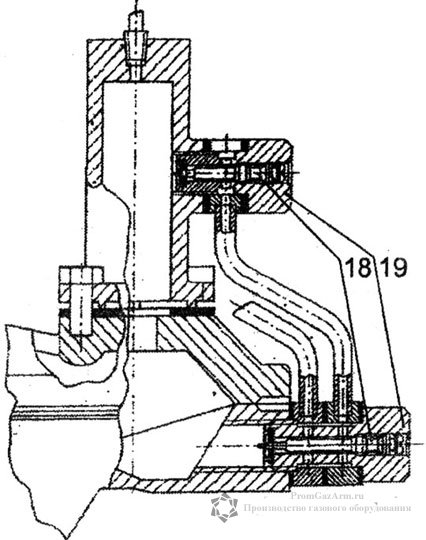

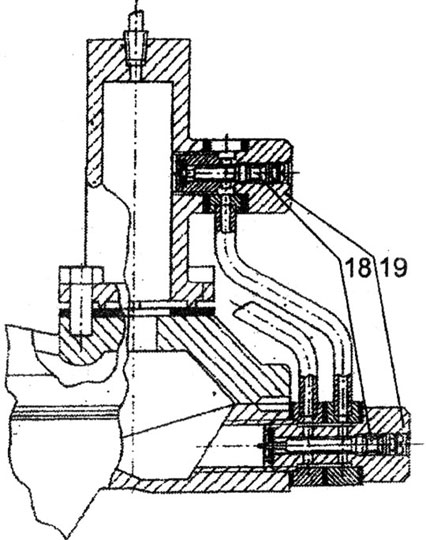

The adjustable chokes 8 and 8a each consist of a choke 18 and a fitting 19 in accordance with Figure 3.

The control mechanism 12 of the shut-off valve is designed for continuous monitoring of the output pressure and issuing a signal for the shut-off valve to operate in the actuator in case of emergency increase and decrease in the output pressure in excess of the permissible set values.

The control mechanism 12 consists of two detachable covers, a membrane assembly clamped around the perimeter of the covers, a control mechanism rod 11, large 22 and small 21 springs, balancing the action of the output pressure pulse on the membrane.

The controller works as follows:

Gas under the inlet pressure enters through the filter 13 to the stabilizer 16, then under the pressure of 0.2 MPa to the control regulator (KN- *) 15 (for the performance of the RDG-N).

From the control regulator (for the performance of the RDG-N) gas through an adjustable throttle 8 enters the submembrane cavity of the actuator.

The supranembrane cavity of the actuator is connected through the throttle 8a and impulse tube 9 to the gas pipeline behind the regulator.

The pressure in the submembrane cavity of the actuator during operation will always be greater than the outlet pressure. The supmembrane cavity of the actuator is under the influence of the outlet pressure. The control regulator (KN-2) (for the performance of the RDG-V) maintains constant pressure, so the pressure in the submembrane cavity will also be constant (in steady state).

Any deviations of the outlet pressure from the predetermined one cause changes in the pressure in the supmembrane cavity of the actuator, which leads to the movement of the valve 4 to a new equilibrium state corresponding to the new values \u200b\u200bof the inlet pressure and flow rate, while the outlet pressure is restored.

In the absence of gas flow, valve 4 is closed, because there is no control pressure drop in the supmembrane and submembrane cavities of the actuator and the action of the outlet pressure.

In the presence of minimal gas consumption, a control pressure drop is formed in the supmembrane and submembrane cavities of the actuator, as a result of which the membrane 6 with the rod 5 connected to it, at the end of which the valve 4 is fixed, will move and open the gas passage through the gap formed between the valve seal and saddle.

With a further increase in gas flow under the action of a control pressure drop in the above actuator cavities, the membrane will move further and the rod 5 with valve 4 will begin to increase the gas passage through the increasing gap between the valve seal 4 and the seat.

If the flow rate through valve 4 decreases, under the action of the changed control differential pressure in the cavities of the actuator, it will reduce the gas passage through the decreasing gap between the valve seal and the seat and subsequently block the seat.

In case of emergency increases or decreases in the outlet pressure, the membrane of the control mechanism 12 moves to the left or right, the shut-off valve lever comes out of contact with the rod 11 of the control mechanism 12, the shut-off valve under the action of the spring 10 blocks the gas flow to the regulator.

In connection with the constant work to improve the regulator, changes to the design that are not reflected in this OM can be made.

Marking and sealing

The regulator is marked with:

- The trademark or name of the manufacturer;

- Regulator designation;

- Product number according to the manufacturer's system;

- Year of manufacture;

- Conditional pass;

- Conditional pressure;

- Conditional bandwidth

- The sign of the direction of flow of the medium;

- Code of technical conditions;

- Mark of compliance with mandatory certification.

The marking is applied on the plate according to GOST 12969-67 and the regulator case, except for the conditional throughput, which is given in the manual.

The marking of the transport packaging corresponds to 1.7 GOST 14192-96 with the application of warning signs according to the drawing RDG-80 TrVSb.

The packaging is filled with the bandage tape M-0.4 ... 0.5x20 along the perimeter of the container GOST 3560-73.

Packaging

The regulator is installed in a wooden box and securely fixed in it. Operational documentation and a set of spare parts are wrapped in waterproof paper, packaged in a plastic bag and placed in a box with a regulator.

Figure 1 (RDG-N gas pressure regulator)

Figure 2 (RDG-V gas pressure regulator)

1-valve shut-off; 2-actuator; 3-saddle; 4-valve working; 5-rod; 6-membrane actuator; 7-throttle washer; 8-chokes adjustable; 9-tube pulse inlet gas pipeline; 10-spring shut-off valve; 11-rod control mechanism; 12-control mechanism; 13-filter; 14-candle; 15-control controller (KN-2); 16-stabilizer; 17-manometer; 18-lever pressure shut-off valve; 19-bracket 20-screw; 21-spring is small; 22-spring is big; 23 staples; 24-bracket; 25 reg. small spring screw; 26 reg. large spring screw; 27-bracket.

Figure 3

18 throttle; 19th fitting.

Intended use

1. Operational restrictions.

1.1. Regulated environment - natural gas according to GOST 5542-87

1.2. The maximum allowable inlet pressure is 1.2 MPa.

2. Preparation of the product for use.

2.1. Unpack the regulator.

2.2. Check the delivery for completeness in accordance with paragraph 1.4.1. RE.

2.3. Check the regulator by external inspection for mechanical damage and the seals.

2.4. Indication of product orientation.

2.4.1. Regulators are installed on a horizontal section of the gas pipeline with the membrane chamber down. Connection of regulators to the gas pipeline is flange in accordance with GOST 12820-80.

2.4.2. The distance from the bottom cover of the membrane chamber to the floor and the gap between the membrane chamber and the wall when installing the regulator in hydraulic fracturing and GRU must be at least 100 mm.

2.4.3. In front of the regulator, a technical pressure gauge MGP-M-1.6MPa - 2.5 TU 25 7310 0045-87 is installed to measure the input pressure.

2.4.4. At the outlet gas pipeline near the exit point of the impulse tube, a double-tube manovacuum meter MV-1-600 (612.9) TU 92-891.026-91 is installed when operating at low pressures or an overpressure pressure gauge MGP-M-0.1MPa - 2.5 TU 25 7310 0045-87 when operating at medium gas pressure to measure the outlet pressure.

2.4.5. The pulse pipeline connecting the regulator to the sampling point must have a diameter of Du for RDG-50 and RDG-80 and Du35 for RDG-150 in accordance with Figure 5. The connection point of the pulse pipeline should be located on top of the gas pipeline at a distance of at least five nominal diameters from output flange of the product.

2.4.6. Local narrowing of the bore of the impulse pipe is not allowed.

2.4.7. the tightness of the actuator, stabilizer, control regulator, control mechanism is checked during a test run of the regulator. In this case, the maximum inlet and one and a half times the outlet pressure is set for this regulator, and the tightness is checked using a soap emulsion. Pressure testing of the pressure regulator, the value of which is higher than specified in the passport is unacceptable.

2.4.8. When carrying out commissioning it is not allowed:

- Overlap of the impulse pipeline connecting the place for measuring the outlet pressure with the regulator column.

- Inlet pressure relief in the presence of outlet and control differential pressure on the working membrane of the regulator's actuator.

2.4.9. To increase the speed of the regulator when operating at inlet pressures of not more than 0.2 MPa, the stabilizer (in RDG-N) is allowed to remove and apply the inlet pressure to the control regulator directly from the filter (according to the RDG-V scheme) in accordance with Figure 2.