You need to quickly buy pipes for gas pipelines at an objectively formed value? Would you like to cooperate exclusively with a reliable and reputable company ready to offer not only a large assortment, but also favorable conditions for cooperation? In this case, you have come to the address! Already today, our catalog contains a large selection of longitudinal seam and seamless hollow metal structures with various diameters of constant section and wall thickness for the equipment of gas transportation systems.

To date, for the transportation of a gaseous medium, electric-welded products of various diameters are used to equip main (surface, underground) gas pipelines with a maximum working pressure of 12.5 MPa.

A high degree of mechanical parameters of the metal used makes it possible to use these products in areas with different climatic conditions, including areas with a prevailing minus ambient temperature.

Pipes for gas pipelines are made of high-quality low-carbon steel, as this material and production method do not lower operational parameters and do not change the formula of the transported product.

Favorable prices for pipes for gas pipelines in Moscow

Would you like to get used reliable metal hollow structures with high operational parameters and physical and mechanical properties? You have studied a lot of offers in the market, but none meet the search criteria? Looking for quality products and objectively formed gas pipe prices? In this case, you simply can not do without our professional help and the assortment presented on the pages of our site!

All products declared in our catalog undergo a special multi-stage system of quality control and compliance with operational parameters prescribed in current norms and standards. The high level of quality of our products is appreciated by our customers throughout Russia.

Today we are ready to provide favorable conditions for cooperation, as well as competitive prices for all products of the secondary metal rolling market. Buy steel gas pipe you need the diameter and length you can with us in an unlimited volume. We also offer prompt delivery of goods by rail or ground special vehicles to any region of the country.

Gas pipesare made only of high quality low carbon steel. It is worth noting that stainless steel is never used in the production process, since the interaction of natural gas and this material producesunions that can greatly reduce the quality of the substance passing through the pipe.

Gas pipes price quite high - this is due primarily to manufacturing technology, since this material is usually cast and not rolled. The fact is that the production of rolling pipes involves the presence of a transverse seam, which is unacceptable when passing gas inside the pipe.

Buy steel gas pipes Today it is possible in many steel companies. Domestic pipes have a high level of quality, which is much higher compared to foreign ones. It is worth noting that the pipes used for laying the gas pipeline can be laid out both in the form of a route and as a technology, which is very important in the construction of serious gas facilities - gas distribution points, compressor stations and others.

The main purpose of gas pipelines is the transportation of combustible mixtures belonging to the category of hazardous substances. This is what necessitates the use of special material to eliminate any leaks. Already at the first stages of universal gasification, steel pipes for gas pipelines were used. And even modern analogues from polymeric materials failed to displace this material from the modern market.

Categories of steel pipes and types of gas pipelines

For laying pipelines, different types of pipes for gas pipelines are used, which are divided into two categories:

- Seamless gas pipes can be hot or cold deformation.

- Welded pipes are distinguished by the type of seam, it can be straight or spiral.

In the production of both categories, the basis is carbon steel, whose grades are specified in GOST 380-2005.

The chemical composition of the steel, as well as the type and size of the gas pipe, are determined by the following factors:

- Working pressure. This parameter can have a high, medium and low rate.

- Pipe Place. It can be underground, ground, underwater, and also located in the room.

- System purpose. The network can be backbone, distribution and backup.

The distribution system is designed to deliver gas to the direct consumer. Pipes for gas supply can have a smaller diameter and thinner walls.

The purpose of the backup network is indicated by its name - special strategic goals. Compliance with high quality is due to the fact that the network is operated only in a specific situation.

Sorting documents

GOST 3265-75 governs the production of water and gas pipes. These pipes are used in the assembly of distribution systems for the supply of natural gas with a working pressure of not more than 1.6 MPa. The diameter of such pipes does not exceed 15 cm, the length is in the range from 4 to 12 meters.

GOST 8734-75 shows the assortment of seamless cold-deformed pipes. They are designed to work under a pressure of 10 MPa. According to the document, pipes can have an outer diameter of no more than 25 cm, and a length of 4.5 to 9 meters.

Advantages and disadvantages of steel pipes for gas pipelines

On the positive side, gas pipes are characterized by the following properties:

- High strength performance.

- Slight linear expansion.

- Ability to work with a medium with high pressure.

- Reliable tight connection in compliance with the rules of joining and the absence of defects.

Among the shortcomings of gas pipes can be noted:

- Condensation due to high thermal conductivity.

- The likelihood of a corrosion process.

- Inflexibility.

- Time-consuming installation by welding.

Rules for the installation of steel gas pipes

- Performance of work in full accordance with the design regulations.

- High-quality matching to avoid possible leaks during the use of the pipeline.

- Installation with tight fit of the pipe to the base.

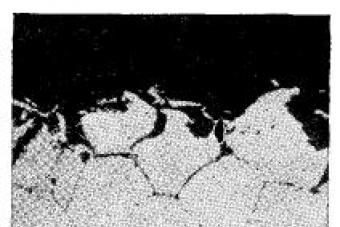

- Preservation of corrosion protection established by the manufacturer. This insulation reduces the susceptibility of the steel pipe to stray current and prevents the formation of corrosion.

- Mandatory treatment of welds with bituminous compounds.

The pipes used for gas pipelines, which are planned to be laid in the ground, must use special factory-made insulation. The technological process of its manufacture has its own characteristics, which makes it impossible to carry out such work on the construction site. In accordance with the ground conditions, the insulation coating can be of a conventional or reinforced design.

Gas is supplied to all consumers through pipelines, no matter how large they are - these are huge enterprises or residents of one-room apartments. Despite the fact that plastic pipes began to occupy a certain segment here in recent decades, steel pipes are still the main routes for transporting gas.

Material requirements

Any steel pipes for gas pipelines need mechanical and electrochemical protection against the corrosion of metal. These highly complex operations require significant financial costs. There are different ways to create a steel structure from different grades of steel. Their choice is influenced by the parameters and purpose of the gas pipelines, pressure, temperature and physicochemical properties of the transported gas.

Gas pipes are divided into:

- Seamless (obtained by cold or hot rolling).

- Welded, having a spiral seam along the entire length.

Pipes are made of either low-carbon steel or high-quality structural steel and must comply with GOST. Carbon, sulfur, and phosphorus are added to the metal. Pipes with a wall thickness of at least 3 mm are taken for underground pipelines, and 2 mm for onshore and aboveground pipelines.

Steel pipe specifications

Pipes are characterized by the following parameters:

- The inner and outer diameter of the wall.

- Nominal diameter.

- Wall thickness.

Since substances are transported in pipelines at high pressures (75 atmospheres or more), the pipes are subject to strict requirements set forth in GOST 20295-85 and many TUs.

In accordance with regulatory documents, only the most durable steel pipes for gas pipelines can be used in construction. As a rule, longitudinal welded or seamless large diameter pipes are used. Their material can only be high-quality carbon steel grades 10 and 20 or low-alloy steel 17G1S.

Protection of steel pipelines

All types of gas pipeline protection must be at a high level. Pipes are protected against external corrosion by means of insulation, which is most often used enamel or a special film, and sometimes insulation with bitumen. From the destruction that may occur due to excess gas pressure above the permissible, the pipeline is protected by safety valves.

For laying underground gas pipelines, polyethylene pipes are widely used today. They are cheaper than steel, but no less reliable and durable. Polyethylene pipes for gas pipelines meet high operational requirements, but they are not suitable for outdoor installation indoors. HDPE can not withstand UV and mechanical stress, therefore, in houses, wiring continues to be made of steel pipes.

What is the advantage of HDPE gas pipes

Polyethylene gas pipes have their own characteristics and advantages, in comparison with steel or propylene analogues. They are considered the best option for transporting the main gas used in domestic as well as industrial sectors.Among the main positive properties of the use of HDPE pipes can be identified:

- a long service period of not less than fifty years;

But do not forget that with an open installation, a gas polyethylene pipe will quickly become worthless under the influence of sunlight.

- low gas permeability of the walls, which ensures complete tightness;

- light weight;

- plastic;

- resistance to corrosion processes, including electrochemical, and aggressive chemical influences;

- trouble-free gas transportation due to the perfect smoothness of the inner surface;

- unnecessary use of additional protective covers;

- lack of need for waterproofing;

- environmental friendliness;

- frost resistance;

- low cost of pipes, fittings and installation, due to the simple technology of the work.

Unfortunately, polyethylene pipes for gas cannot be used everywhere. This is due to multiple requirements in relation to them. First of all, HDPE pipes cannot be used in residential premises.

Destruction of the structure of the material from ultraviolet radiation can lead to gas leakage, which is unsafe.

Polyethylene pipes installed on gas pipelines with high working pressure must not be laid under roads and in those places where super-intense loads are possible. In such cases, it is necessary to first lay the covers or channels in which the gas pipelines will be placed.

It is also impossible to use HDPE pipes for gas in regions with an increased level of seismic activity. These requirements relate to gas pipelines of categories I and II, which corresponds to operating parameters of 6-12 atm. and 3-6 atm. respectively.

Range and classification of products

Two types of pipes are made for gas pipelines:

- PE100 - for operating pressures up to 3, 6, 10 and 12 atmospheres;

- PE80 - for operating pressures up to 3 and up to 6 atmospheres.

Products are sold in bays up to 200, sometimes up to 500 meters, or in segments of 13 meters, depending on the diameter. The PND gas pipe is black with a marking in the form of longitudinal strips of yellow (PE80) or orange (PE100). On its outer surface, technical data is necessarily applied with paint of the corresponding color, indicating:

- name of the manufacturer;

- destination (gas);

- polyethylene grade in the international format (PE100 or PE80);

- sDR value

- outer diameter and wall thickness in millimeters;

- GOST;

- production date with batch number.

Pipes for gas pipelines have a diameter of 16 to 400 mm.

Designations MRS and SDR

Gas piping HDPE pipes have designations that the ordinary consumer can puzzle. Let's try to figure them out.

Mrs. This indicator indicates the minimum long-term strength of polyethylene. In other words, this is the ability of PND to withstand loads expressed in megapascals. For PE80 MRS is 8MPa, for PE100 - 10MPa.

SDR Translated from English - "Standart Dimension Ratio" means "standard size ratio." This indicator can be represented as the ratio of the outer diameter to the thickness of the pipe wall.

It should be noted that the larger the SDR parameter, the thinner the pipe wall will be.

Installation of gas pipelines from PND

The main task when laying gas pipelines is to ensure their tightness. Even a child knows that a gas leak can lead to serious consequences, and in the worst case, to victims. Therefore, the installation of gas pipelines should be approached with all responsibility.

To connect HDPE pipes, thermistor fittings are produced, which are installed at the joints by welding. In addition, crimp (compression) as well as split flange fittings are used.

As connecting parts use:

- turns of 45 and 90 degrees:

- couplings;

- stubs;

- adapters;

- tees.

Welds provide the most reliable connection during the entire period of operation of the gas pipeline.

HDPE pipes made of low-pressure polyethylene are becoming more and more widely used in the construction of gas pipelines. Contrary to the common misconception, the words “low pressure” in the name “HDPE pipes” refer to the method of producing polyethylene, and not to the gas pipeline category - polyethylene gas pipes can be used on gas distribution networks of low, medium and high pressure - up to 1.2 MPa.

In Europe, pipes for gas pipelines are produced in accordance with ISO 4437. Our national standard, GOST R 50838, is a modified version of this document, taking into account the characteristic conditions for laying and operating gas pipelines in Russia. One of the most significant changes is the ban on the use of recycled (obtained from pipe processing) polyethylene - in the original ISO 4437 there is no such restriction.

This is one of the few cases when our domestic product requirements are stricter than foreign ones.

Description of polyethylene pipes

Polyethylene pipes for gas pipelines are produced from special pipe grades of polyethylene classified as PE 80 and PE 100. The class of polyethylene is established by lengthy (over a year) internal pressure tests and allows you to calculate the maximum working pressure at which the gas pipe will last at least 50 years at a temperature of 20 ° C. Pipes made of PE 100 with the same wall thickness can operate at a higher internal pressure than pipes made of PE 80. It is important to note that only primary polyethylene is used in the production of gas pipes.

The range of products of the POLYPLASTIC Group includes pipes made of polyethylene for gas pipelines according to GOST R 50838 with a diameter of 20 to 630 mm, as well as polyethylene pipes for underground gas distribution and gas consumption networks with a diameter of up to 1200 mm, manufactured at

TU 2248-010-73011750-2010. All supplied products for gas pipelines have a full set of permits.

In addition to the class of polyethylene and diameter, polyethylene pipes are characterized by the ratio of diameter to wall thickness - SDR. The lower the SDR value, the thicker the pipe wall, and the greater the pressure such a pipe can withstand. POLYPLASTIC Group produces pipes for gas pipelines with SDRs from 9 to 26.

The color of the gas pipe may be black, yellow, or orange. Black gas pipes have longitudinal indelible yellow stripes that distinguish a laid gas pipeline from pipelines for other purposes. Each pipe has a marking repeated across the meter that contains information on: material, pipe size, its purpose, information about the manufacturer, lot and production date. Example of pipe marking: “POLYPLASTIC PE 100 GAS Group SDR 11 63x5.8 GOST R 50838-2009 04/15/2015 K05017-15 change 2".

HDPE pipe properties

HDPE pipes have several advantages that are important both for the operating organization and for the builder, which makes them the best solution for the construction of gas distribution systems of any level - from gasification of a country house to construction of gas distribution networks on a megalopolis or small settlement scale.

Polyethylene is an excellent insulator, due to which HDPE pipes are immune to stray currents.

Pipes made of polyethylene are chemically resistant to transported natural gas, are not susceptible to corrosion under the influence of moisture from the surrounding air, so they do not require an electrochemical protection device. In addition, due to the absence of corrosion processes during operation, the pipe does not overgrow and does not reduce its throughput.

Due to their flexibility, polyethylene pipes are not damaged when moving soils, even significant ones. This allows us not to fear for their safety when laying gas pipelines in unstable soils and seismically active areas. The permissible bending radius for the HDPE pipe is 25 diameters, which is almost 50 times smaller than steel pipes, which allows the use of long pipes with a diameter of up to 180 mm, delivered to the object in bays or on coils (drums), which greatly simplifies the installation process and minimizes the number of welded joints. When using polyethylene pipes, various methods of trenchless reconstruction of old worn-out pipelines in cramped urban conditions can be effectively applied, as well as a new trenchless installation using directional drilling.

The service life of a polyethylene pipe is at least 50 years, and under favorable conditions, when the gas pressure is less than the calculated one and its temperature is below 20 ° C, it can exceed 100 years.

HDPE pipes have a significantly lower weight than steel pipes, which simplifies their transportation and installation.

Unfortunately, HDPE pipes are limitedly resistant to ultraviolet rays, therefore, such pipes cannot be used for overhead installation. In addition, polyethylene is a combustible material, which does not allow the use of pipes from it for laying gas pipelines indoors.

Installation of polyethylene gas pipelines

Polyethylene pipes can be connected by butt welding or by welding parts with electric heaters, while the strength of the connection made in compliance with the welding technology is higher than the strength of the pipe itself. Equipment necessary for the installation of polyethylene gas pipelines can be purchased or leased from the POLYPLASTIC Group.

A wide range of bends, equal and unequal tees allows you to build a gas pipeline of any complexity, and the AEON and GF shut-off valves supplied by the POLYPLASTIC Group complete the complete set of gas distribution and gas consumption networks.

For the transition from a steel pipe to a polyethylene pipe, one-piece polyethylene-steel joints can be used. One side of such a connection is welded to steel, the second to a polyethylene pipe.

We also supply saddle bends, which are used to connect new consumers to an existing gas pipeline without reducing pressure in it for the time of insertion.

Training and certification of welders conducted by the POLYPLASTIC Group, as well as installation and installation supervision services, allows our customers to avoid problems in the construction of polyethylene gas pipelines.

The cost of polyethylene pipes

Despite the fact that polyethylene gas pipes are more expensive than water pipes, primarily because of more stringent requirements for raw materials and a wider range of necessary tests, the price of an HDPE gas pipe is lower than for steel pipes.

Due to savings at cathodic protection stations (including operating costs and consumed electricity) or the absence of the need for periodic surface painting of gas pipelines necessary for their elevated installation, as well as lower costs for the operation of polyethylene gas pipelines associated with their high reliability and durability, the total cost of living the cycle (with a longer service life) of polyethylene gas pipelines (design, construction and operation) is much lower than steel.

You can buy pipes according to GOST R 50838 or TU 2248-010-73011750-2010 by leaving an order on the website or by contacting one of our regional divisions.