Edge preparation for welding. The shape of the prepared edges for welding.

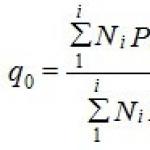

Edge preparation for welding.Elements of the geometrical form of preparing the edges for welding (Fig. 25) include the angle of cutting edges α, blunting edges S, the length of the bevel of the sheet L in the presence of a difference in the thickness of the metal, the displacement of the edges relative to each other b, the gap between the abutting edges a.

Fig. 25. Elements of the geometric shape of the preparation of the edges for welding (a)and seam (b):

in - seam width, h - seam height, K - seam leg

The angle of cutting edges is performed with a metal thickness of more than 3 mm, since its absence (cutting edges) can lead to lack of penetration along the cross section of the welded joint, as well as to overheating and burning of the metal; in the absence of cutting edges to ensure penetration, the welder must increase the value of the welding current.

Cutting the edges allows welding in separate layers of a small cross section, which improves the structure of the welded joint and reduces the occurrence of welding stresses and deformations.

The gap, correctly set before welding, allows for full penetration over the connection cross section when applying the first (root) layer of the seam, if the appropriate welding mode is selected.

The length of the bevel of the sheet regulates a smooth transition from a thick welded part to a thinner, stress concentrators in welded structures are eliminated.

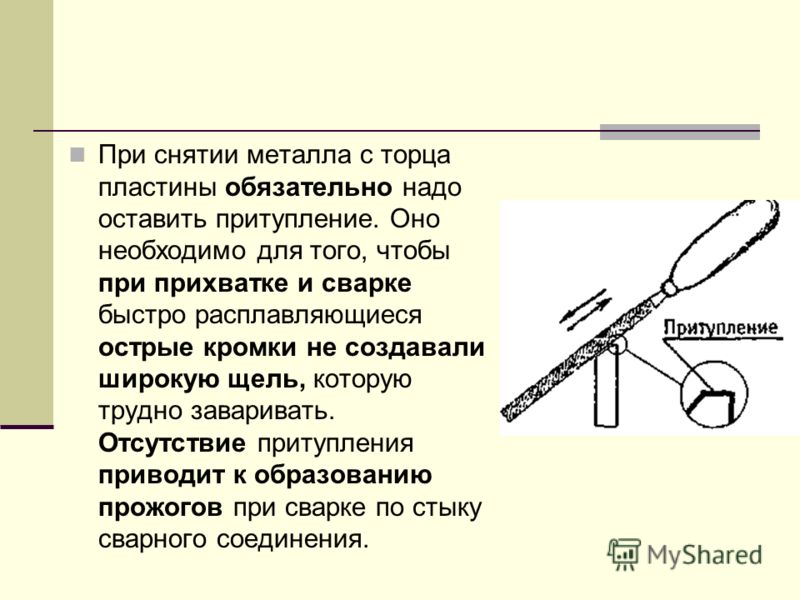

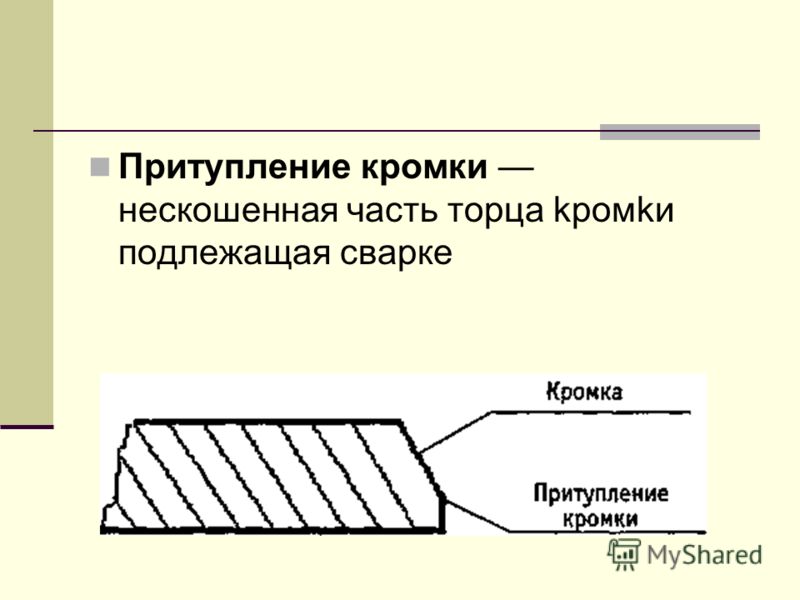

The blunting of the edges is performed to ensure stable conduct of the welding process when performing the root layer of the seam. The lack of blunting contributes to the formation of burns during welding.

The offset of the edges creates additional welding strains and stresses, thereby impairing the strength properties of the welded joint. Edge offset is regulated by either GOSTs or technical conditions. In addition, the offset of the edges does not allow to obtain a monolithic weld along the cross section of the welded edges.

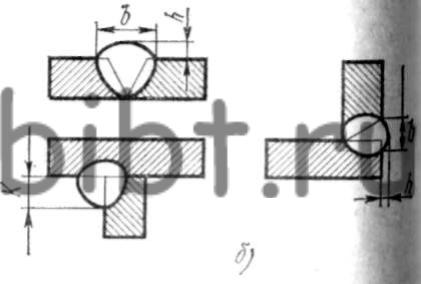

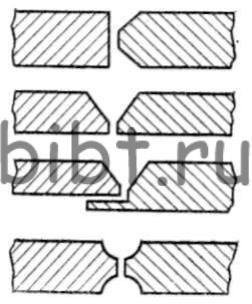

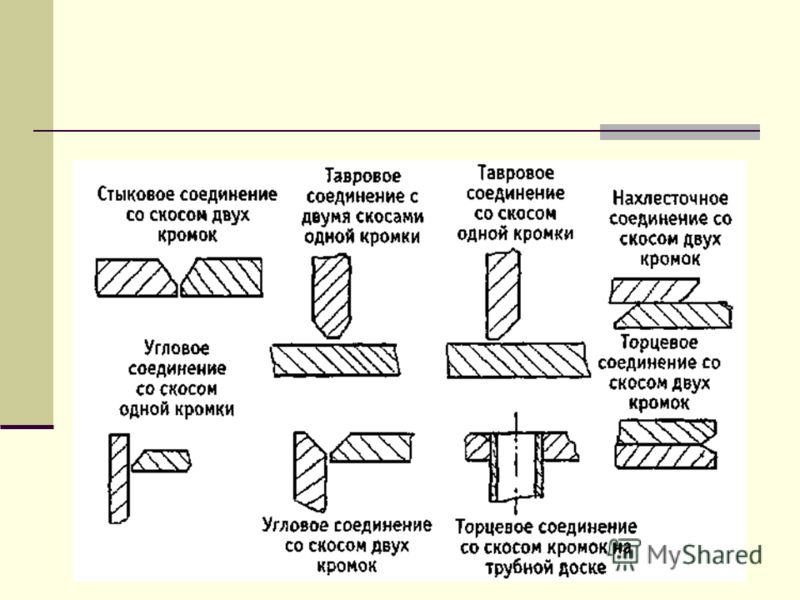

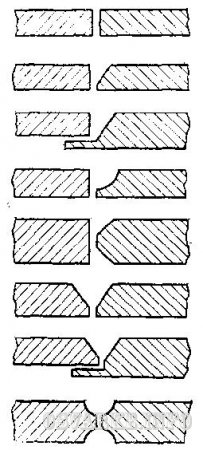

GOST 5264-80 provides for butt joints the shapes of the prepared edges shown in Fig. 26; for corner joints - in fig. 27; Tauri - in Fig. 28 and lap joints - in fig. 29.

Fig. 26. The shape of the prepared edges for welding for butt joints

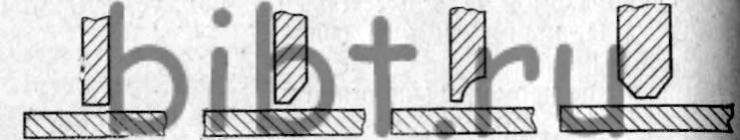

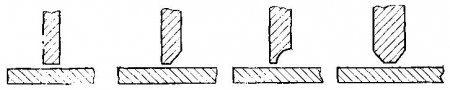

Fig. 27. Shape of prepared weld edges for corner joints

Fig. 28. Form of prepared weld edges for T-joints

Fig. 29. The shape of the prepared weld edges for lap joints

The preparation of the edges for welding is carried out on mechanical lathes (processing of pipe ends), milling, planing - processing of sheets, etc., as well as the use of thermal cutting. Sheets, pipes made of carbon steels are processed by oxy-fuel cutting. Acetylene, propane, coke oven gas, etc. can serve as combustible gases. Non-ferrous metals, as well as stainless steels, are processed by plasma cutting.

Before welding particularly critical structures, the ends of the pipes or sheets after oxy-fuel cutting are additionally processed mechanically; this is done in order to avoid any inclusions in the metal.

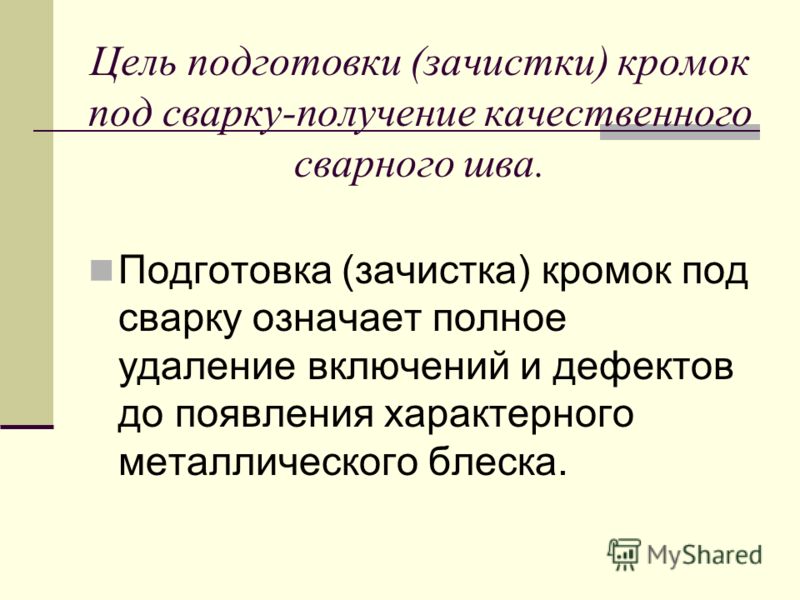

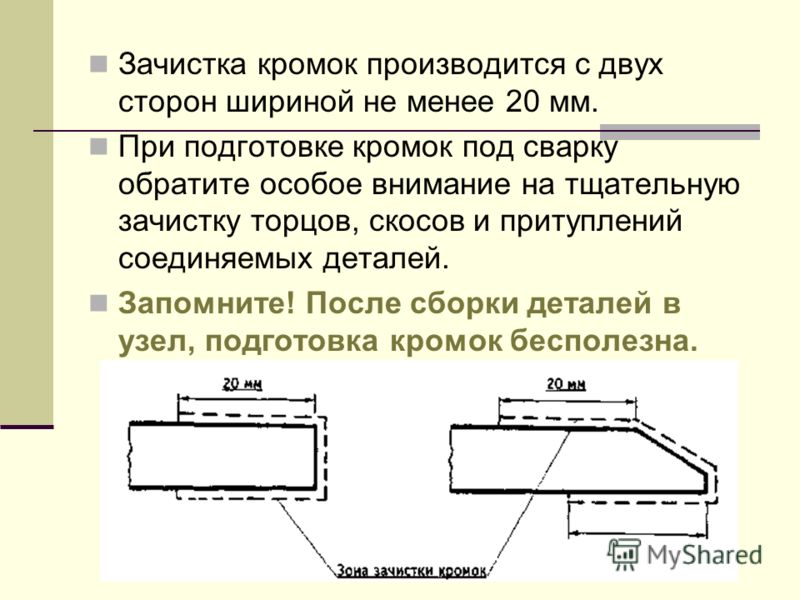

Edge trimming is performed on both sides with a width of at least 20 mm. When preparing the edges for welding, pay special attention to the thorough cleaning of the ends, bevels and blunts of the parts to be joined. Remember! After assembling parts into a knot, edge preparation is useless ..

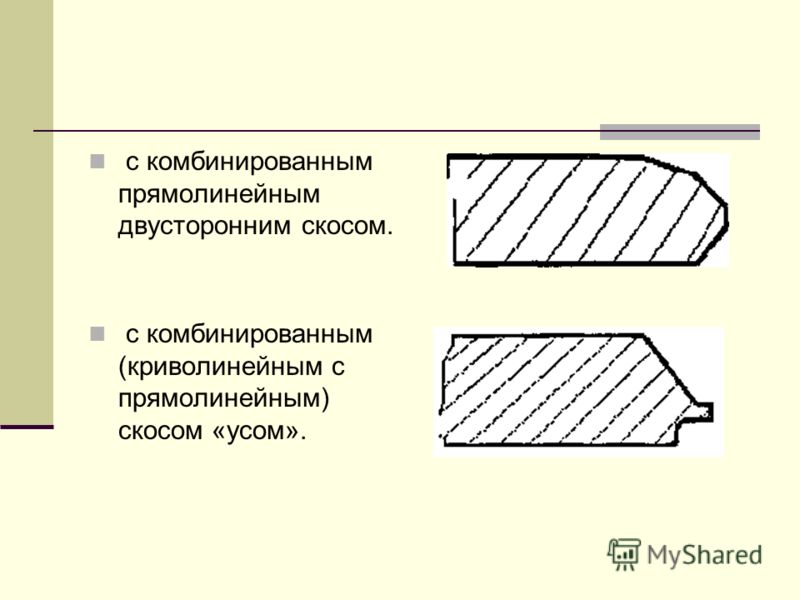

The essence of the preparation of cutting edges for welding On the butt end of the plate is removed part of the metal at a certain angle (bevel angle). Edge bevel A straight inclined edge slice to be welded. Bevel angle of the edge (c) an acute angle between the plane of the bevel of the edge and the plane of the end.

When removing metal from the end of the plate, be sure to leave a blunt. It is necessary so that during tacking and welding, quickly melting sharp edges do not create a wide gap, which is difficult to weld. The lack of blunting leads to the formation of burns during welding at the joint of the welded joint.

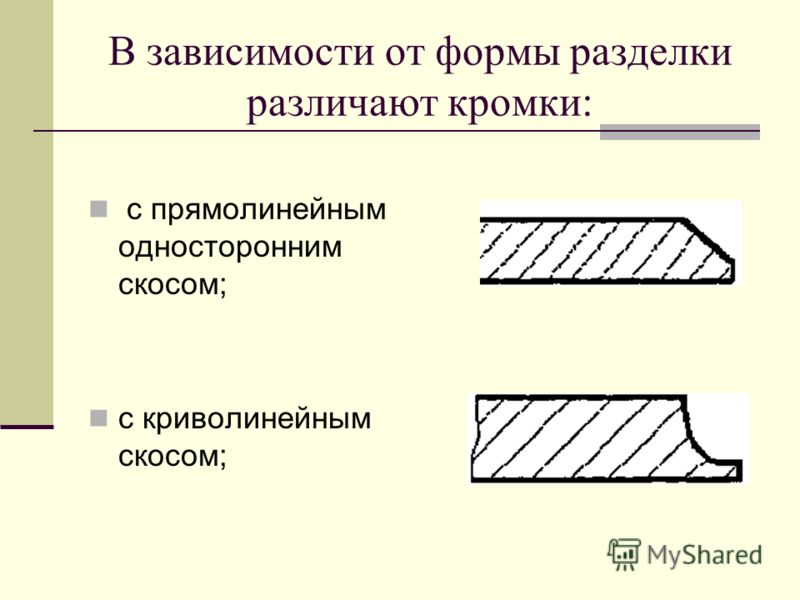

The shape of the cutting edges is characterized by the angle of their bevel, the size of the blunting and the gap between the welded edges. It depends on the type of weld (butt, corner, tee, lap, butt), the thickness of the welded elements. Edging Form

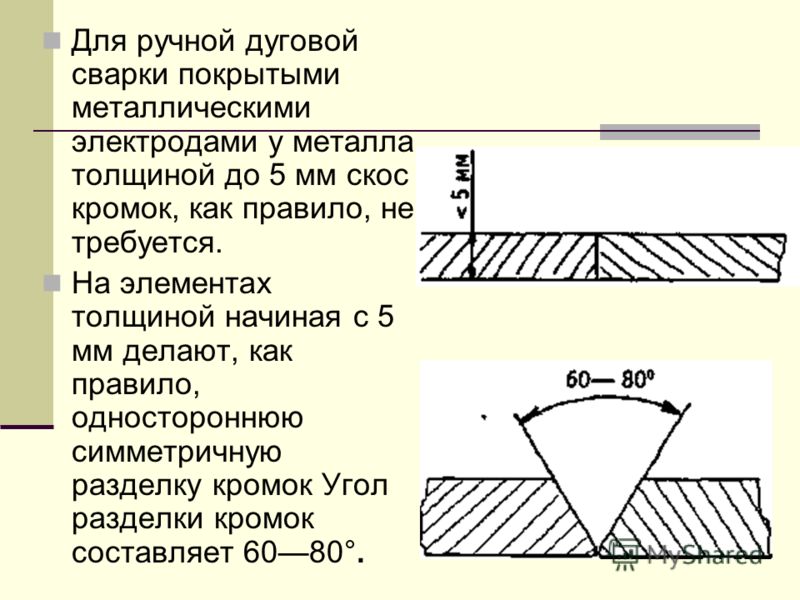

For manual coated arc welding metal electrodes for metals up to 5 mm thick, beveling of the edges is usually not required. On elements with a thickness starting from 5 mm, as a rule, a one-sided symmetrical grooving is made. The angle of grooving is 6080 °.

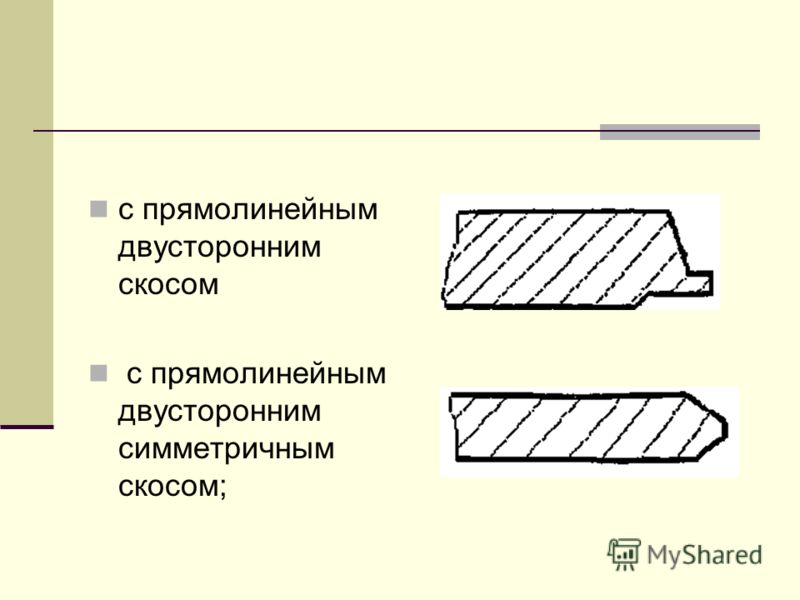

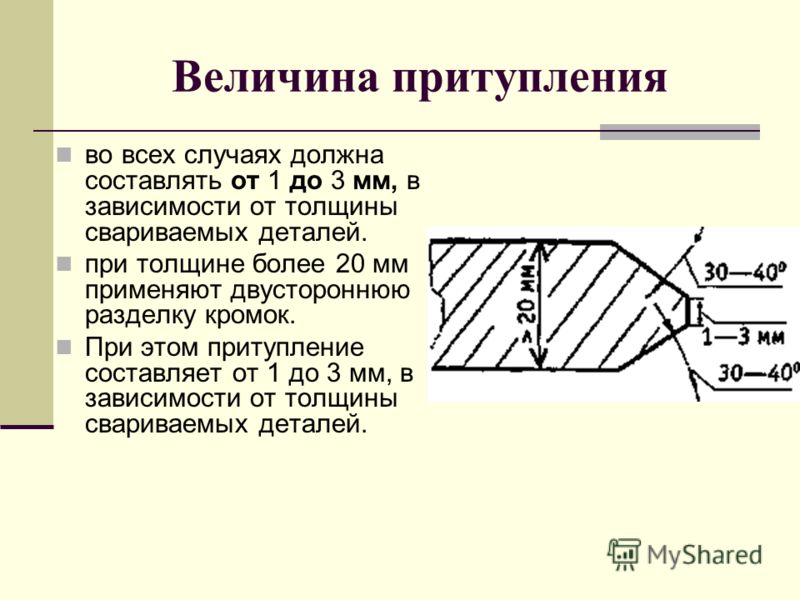

The blunting value in all cases should be from 1 to 3 mm, depending on the thickness of the parts to be welded. with a thickness of more than 20 mm, two-sided cutting of edges is used. In this case, the blunting is from 1 to 3 mm, depending on the thickness of the parts to be welded.

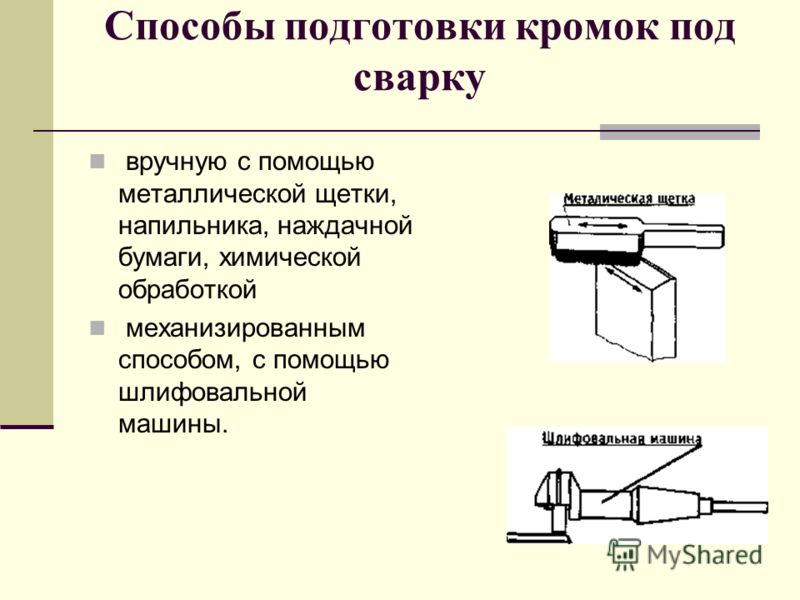

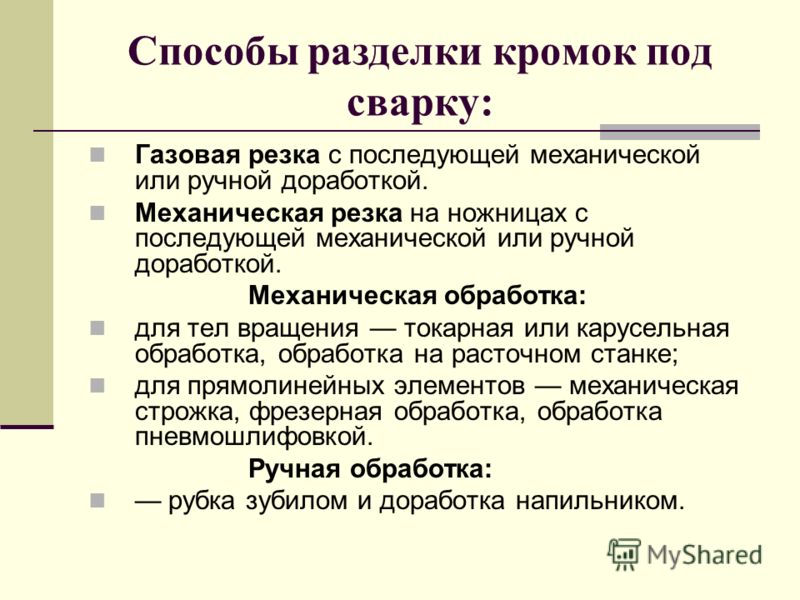

Methods for cutting edges for welding: Gas cutting with subsequent mechanical or manual revision. Mechanical cutting with scissors, followed by mechanical or manual refinement. Machining: for bodies of revolution, turning or rotary machining, machining on a boring machine; for straight-line elements, mechanical gouging, milling, pneumatic grinding. Manual processing: cutting with a chisel and finalization with a file.

§ 28. Preparation of metal for welding

Preparation of the metal surface for welding. When preparing parts for welding, the incoming metal is subjected to dressing, marking, basting, cutting, preparing edges for welding, cold or hot bending.

Metal is corrected either manually or on various sheet straightening rollers. Manual dressing is performed on cast iron or steel regular plates by hammer blows or using a manual screw press. Corner steel is corrected on the right rollers (presses), I-beams and channels - on driven or manual leveling presses.

Marking and basting are operations that determine the configuration of a future part. Mechanical cutting is used for straight cutting of sheets, and sometimes for curved cutting of sheets using roller scissors with circular knives for this purpose. Carbon steels are cut by oxy-fuel and plasma-arc cutting. These methods can be manual and mechanized. For cutting alloy steels and non-ferrous metals, gas flux or plasma-arc cutting can be used.

The base metal and filler material must be thoroughly cleaned from rust, oil, moisture, scale and various non-metallic contaminants before welding. The presence of these contaminants leads to welds pores, cracks, slag inclusions, which leads to a decrease in the strength and density of the welded joint.

Edge preparation for welding. Elements of the geometric shape of preparing the edges for welding (Fig. 25) include the angle of cutting edges α, blunting the edges S, the length of the bevel of the sheet L in the presence of a difference in the thickness of the metal, the offset of the edges relative to each other b, the gap between the abutting edges a.

Fig. 25. Elements of the geometric shape of the preparation of the edges for welding (a) and weld (b):

in - seam width, h - seam height, K - seam leg

The angle of cutting edges is performed with a metal thickness of more than 3 mm, since the absence of (cutting edges) can lead to lack of penetration along the cross section of the welded joint, as well as to overheating and burning of the metal; in the absence of cutting edges to ensure penetration, the welder must increase the value of the welding current.

Cutting the edges allows welding in separate layers of a small cross section, which improves the structure of the welded joint and reduces the occurrence welding voltage and deformations.

The gap, correctly set before welding, allows for full penetration over the connection cross section when applying the first (root) layer of the seam, if the appropriate welding mode is selected.

The length of the bevel of the sheet regulates a smooth transition from a thick welded part to a thinner, stress concentrators in welded structures are eliminated.

The blunting of the edges is performed to ensure stable conduct of the welding process when performing the root layer of the seam. The lack of blunting contributes to the formation of burns during welding.

The offset of the edges creates additional welding strains and stresses, thereby impairing the strength properties of the welded joint. Edge offset is regulated by either GOSTs or technical specifications. In addition, the offset of the edges does not allow to obtain a monolithic weld along the cross section of the welded edges.

GOST 5264-80 provides for butt joints the shapes of prepared edges shown in Fig. 26; for corner joints - in fig. 27; Tauri - in Fig. 28 and lap joints - in fig. 29.

Fig. 26. The shape of the prepared edges for welding for butt joints

Fig. 27. The shape of the prepared edges for welding for corner joints

Fig. 28. The shape of the prepared edges for welding for T-joints

Fig. 29. The shape of the prepared edges for welding for lap joints

The preparation of the edges for welding is performed on machine tools - turning (pipe end processing), milling, planing - sheet processing, etc., as well as the use of thermal cutting. Sheets, pipes made of carbon steels are processed by oxy-fuel cutting. Acetylene, propane, coke oven gas, etc. can serve as combustible gases. Non-ferrous metals, as well as stainless steel processed by plasma cutting.

Before welding particularly critical structures, the ends of the pipes or sheets after oxy-fuel cutting are additionally processed mechanically; this is done in order to avoid any inclusions in the metal.

Assembly requirements for metal parts before welding. The used assembly and welding devices must ensure accessibility to the places of installation of parts and tacks, to the handles of fixing and clamping devices, as well as to the places of welding. These devices must also be sufficiently strong and rigid, to ensure accurate fastening of parts in the desired position and prevent their deformation during welding. In addition, assembly and welding devices must provide the most favorable assembly and welding procedure: the least number of turns when applying tacks and welds; free access for checking the size of products and their easy removal after manufacture; safety of assembly and welding operations.

Any assembly operation should not impede the following operation. Assembly parts must be carefully checked; All geometric dimensions of the part and the prepared shape of the edges for welding are subject to verification.

Assembly of welded structures, as a rule, is carried out either by marking, or using templates, stops, clamps or special devices - conductors that facilitate assembly operations. Preparation and assembly of products for welding is carried out in compliance with the following basic mandatory rules:

blunting of the edges and the gaps between them should be uniform along the entire length;

the edges of the elements to be welded and adjacent areas 25-30 mm wide from the end of the edge should be dried, cleaned from burrs after cutting, oil, rust and other contaminants;

in order to avoid deformation, the tack should be performed with high-quality electrodes through an interval of not more than 500 mm with a length of one tack of 50-80 mm;

to ensure normal and high-quality formation of the seam, it is necessary to grasp the trims at the beginning and at the end of the product.

The preparation of metal for welding includes dressing, marking and basting, cutting and edging, cold and hot bending. Editing is carried out mainly on machines, and sometimes manually. Sheet, strip and profile rolling rule on rollers, which most often have seven or nine rolls.

The rollers are equipped with two roller tables for loading and exiting the metal during the dressing process. When editing sheets are passed through the rollers from 3 to 5 times.

Along with machine editing, manual editing is sometimes used. The latter is produced on cast iron or steel regular plates by hammer blows, sledge hammers and using a screw press.

Editing of angular steel is carried out on carbon straightening rolls or on manual screw presses, and I-bars and channels - on driven or manual straightening presses.

Marking and basting. In individual production, the straightened metal enters for marking, while in mass and mass production it enters for marking. Before marking and basting, the metal surface is primed with chalk paint on the glue.

When marking the same type of parts for mass and mass production, metal or plywood templates are used. Template markup is called basting. Tools for marking and marking are hardened steel scriber, punch, steel rulers and squares, steel compasses and planes, hammers, clamps, clamps, steel roulettes, etc.

Cutting. Metal cutting into workpieces is carried out mechanically on scissors and saws or with an oxygen flame. Mechanical cutting is carried out mainly on scissors and is mainly used for straight cutting of sheets up to 20 mm thick. The most widely used are guillotine shears with knives from 1 to 3 m long and press shears with knife lengths up to 700 mm.

For curvilinear cutting of thicknesses up to 6 mm, roller scissors with circular knives are used. For straight cuts of large thicknesses and for curvilinear cuts of thicknesses above 6 mm, manual, semi-automatic and automatic gas-oxygen cutting is used. For cold cutting of rods of round and other sections, round (circular) gear and friction saws are used.

Edging for welding. Processing and beveling of the edges for welding are performed mechanically on edge-cutting and longitudinal-planing machines or with an oxy-fuel flame. With a small amount of work, cutting is sometimes used with a pneumatic chisel. Bending. Bending of sheet, strip and broadband metal is carried out on sheet bending three-roll and four-roll rollers. Sheets with prepared edges and cut holes of small diameters come to cold bending. Profile metal bending is carried out on press brake and roller bending mills. The smallest permissible radius of steel bending in the cold state is recommended to be taken equal to 25 times the sheet thickness or the height of the symmetrical profile. If the radius of cold bending is less than 25 thicknesses of the deformable steel, then tearing of the outer fibers is possible.

Bending of large thicknesses and bending of shells of small diameter, with an average thickness of the sheet, is carried out hot in the forging shops. The parts are heated to a temperature of 1000-1100 ° С, at which the metal is easily amenable to deformation. Edging for welding and cutting large holes is done after hot bending.

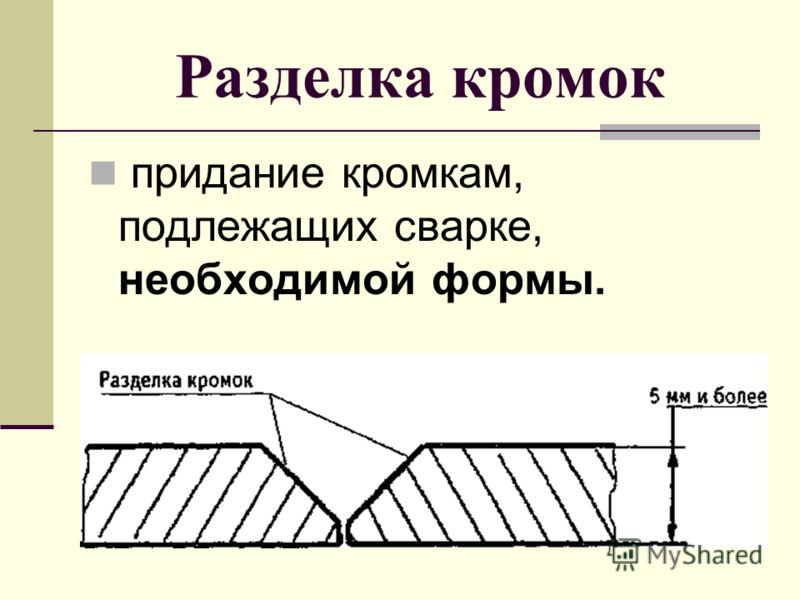

Cutting edges - giving the edges to be welded to the desired shape.

Cutting edges for welding is performed in order to ensure:

Provara through the entire thickness of the elements to be welded;

Access of the welding tool to the root of the seam.

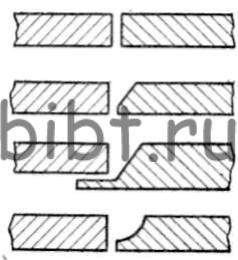

According to the shape of cutting edges for welding, there are distinguished welded joints without cutting edges, with flanging and with cutting edges for welding. In addition, welded joints with grooves are divided into welded joints with one-sided beveling of one or two edges (one-sided grooving of one or two edges) and welded joints with two-sided beveling of one or two edges (two-sided grooving of one or two edges).

When choosing the shape of the cutting edges, it should be borne in mind that the most economical is a welded joint without bevel edges. In the case of cutting edges more simple in execution compared to the U-shaped is the cutting of edges with a straight bevelled edges (V, K, X - shaped). In comparison with one-sided cutting of edges, K- and X-shaped bilateral are more technologically advanced. However, K- and X-shaped double-sided can be implemented if the welding tool can be accessed on both sides of the product.

Edging for welding

MDK 02.01. Equipment, machinery and technology for electric welding

PM.02. Welding and cutting of parts from various steels, non-ferrous metals and their alloys, cast irons in all spatial positions

by profession 150709.02 Welder (electric welding and gas welding).

Testing is a milder tool, they put all students on an equal footing, using a single procedure and common assessment criteria, which leads to a decrease in pre-examination nervous stresses.

Download:

Preview:

budgetary educational institution of the Omsk region

primary vocational education

"Vocational school number 65."

TEST

Edging for welding

MDK 02.01. Equipment, machinery and technology for electric welding

PM.02. Welding and cutting of parts from various steels, non-ferrous metals and their alloys, cast irons in all spatial positions

By profession 150709.02 Welder (electric welding and gas welding)

Compiled by: Baranov Vladimir Ilyich Master of Industrial Training

Sedelnikovo, Omsk Region, 2013

Cutting edges for welding.

Test.

Each question has one or more correct answers. Choose the faithful.

1. Edge cutting is performed:

a) to improve welding conditions and obtain guaranteed penetration;

b) based on aesthetic considerations;

c) to prevent welding deformations.

2. Starting with what thickness on the plates, as a rule, beveling of the edges is usually done?

a) 3 mm.

b) 5 mm.

c) 8 mm.

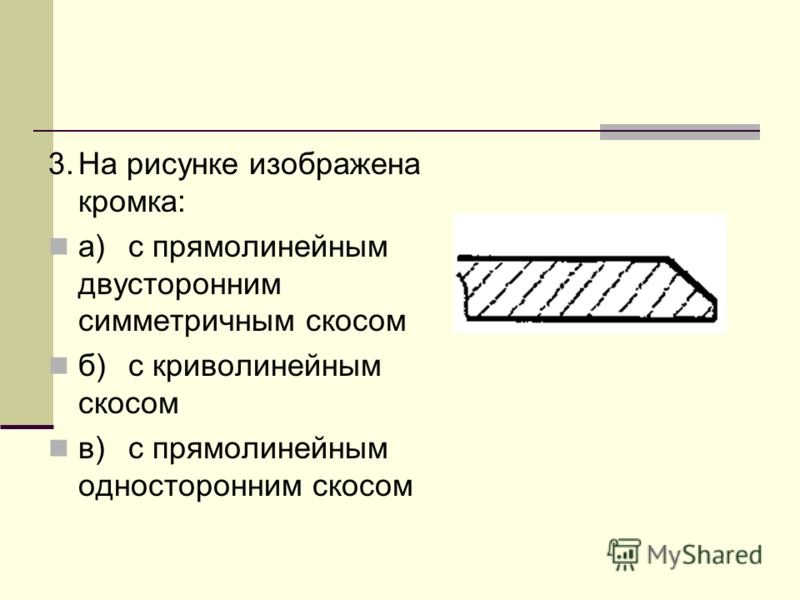

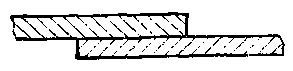

- The figure shows the edge:

a) with rectilinear bilateral

symmetrical bevel;

b) with a curved bevel;

c) with a rectilinear unilateral bevel.

- What is called bevel angle?

a) An acute angle between the plane of the bevel of the edge and the plane of the end.

b) An acute angle between the plane of the bevel of the edge and the plane of the plate.

c) Dull angle between the plane of the bevel of the edge and the plane of the end.

- The angle of cutting edges is:

a) 45-60 °;

b) 60-80 °;

c) 80-100 °.

6. The amount of blunting of the edges in all cases should be:

a) from 1 to 3 mm;

b) from 3 to 4 mm;

C) from 4 to 5 mm.

- On plates of what thickness is it advisable to make two-sided beveling of the edges?

a) 10 mm.

b) 6 mm.

c) 20 mm or more.

- Metal removal using a chisel and hammer is acceptable for plate thickness, starting:

a) with 8 mm;

b) with 3 mm;

c) with 20 mm.

- In one pass, a chisel removes a layer of metal thick:

a) 2 mm;

b) 5 mm;

c) 4 mm.

10. When finishing the edge with a file you must:

a) reach the edge of the core mark;

b) remove half of the core mark;

c) remove the core mark completely.

Answer standard:

Test Evaluation Criteria:

The rating is “excellent” 9-10 correct answers or 90-100% of 10 proposed questions;

Evaluation “good” 7-8 correct answers or 70-89% of 10 proposed questions;

Assessment “satisfactory” 5-6 correct answers or 50-69% of 10 proposed questions;

The rating is unsatisfactory ”0-4 correct answers or 0-49% of the 10 proposed questions.

List of references

- Galushkina V.N. The technology of production of welded structures: a textbook for the beginning. prof. education. - M.: Publishing Center "Academy", 2012;

- Ovchinnikov V.V. Technology of manual arc and plasma welding and metal cutting: a textbook for the beginning. prof. education. - M.: Publishing Center "Academy", 2010;

- Maslov V.I. Welding works6 Textbook. for the beginning. prof. Education - M .: Publishing Center "Academy", 2009;

- Ovchinnikov V.V. Equipment, machinery and technology for welding and cutting of metals: textbook - M .: KNORUS, 2010;

- Kulikov O.N. Labor protection in the production of welding: textbook. allowance for the beginning. prof. Education - M .: Publishing Center "Academy", 2006;

- Vinogradov V.S. Electric arc welding: a textbook for the beginning. prof. Education - M .: Publishing Center "Academy", 2010.