Seamless pipes made of stainless alloys are indispensable in production and in conditions where transportation or transmission of media (gases or liquids) is required, characterized by high temperatures, pressure and / or chemical aggressiveness. Due to the versatility of their characteristics, metal products made of metal 12X18H10T, manufactured in accordance with GOST 9941-81, are one of the most popular in various fields.

1 Seamless pipes 12X18H10T according to GOST 9941-81 - how are they produced?

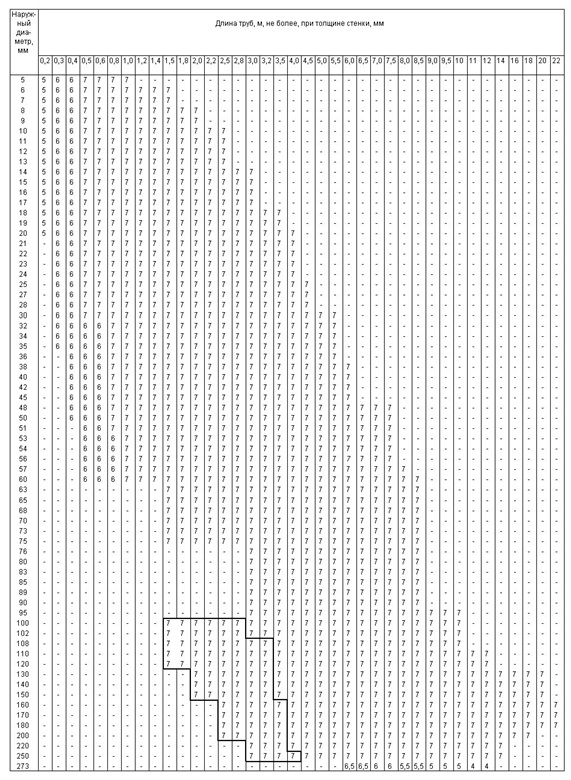

GOST 9941-81 applies to cold and heat-deformed seamless pipes made from corrosion-resistant steel alloys of general purpose, including the grade 12X18H10T. These pipes are produced with diameters (outer) of 5–273 mm and with walls 0.2–22 mm thick. A full assortment, as well as technical characteristics of the products are indicated in the same standard - GOST 9941-81.

Depending on the size of the wall thickness and diameter, the standard maximum length of manufactured pipes is 4–7 m. For ease of use for various purposes, products are manufactured with the following lengths:

- Unmeasured length from 0.75 m to the maximum standard value - for pipes with wall thickness up to 0.5 mm.

- Unmeasured from 1 m to the maximum standard value - for products with walls 0.5–1 mm.

- Unmeasured within 1.5–12.5 m for pipes with walls of 1 mm and thicker.

- Dimensional - within the boundaries of non-dimensional and at the same time no longer than the maximum standard value with a maximum deviation of +15 mm. By mutual agreement of the consumer with the manufacturer, it is allowed to produce rolled products with a measured length greater than the maximum standard.

- Multiple measured - within the boundaries of the measured, if necessary, with an allowance of 5 mm per cut and a maximum deviation of the total length of +15 mm. The smallest multiple length is 300 mm.

- By agreement of the consumer with the manufacturer, it is allowed to produce rolled steel with a length of more than 12.5 m.

- By agreement of the consumer with the manufacturer, products with a diameter of less than 25 mm are allowed to be manufactured up to 16 m long.

In terms of manufacturing accuracy, pipes are produced with ordinary accuracy, with increased, with high.

For each type, depending on the pipe size, GOST 9941 regulates the corresponding maximum deviations (tolerances) of the wall thickness and diameter. The curvature of the rolled pipe in any section with a length of 1 m should not exceed:

- 1 mm - for products of all diameters having walls with a thickness of 0.5 mm or more;

- 2 mm - for products in which the diameter exceeds 15 mm and the wall has a thickness of less than 0.5 mm.

For rolled products having a diameter of less than 15 mm and a wall with a thickness of less than 0.5 mm, the norms for curvature are not regulated. These products should not have sharp bends.

Regarding the ends of the pipes GOST established the following requirements. Their pruning is performed at an angle of 90 ° (straight) and they must be cleaned from burrs. When removing the latter, the formation of roughness and chamfer is allowed. At the request of the customer, pipes with a wall thicker than 5 mm are delivered with ends with a chamfer for welding.

2 Weight of seamless pipes 12X18H10T manufactured in accordance with GOST 9941-81

GOST 9941-81 does not contain data on the specific gravity (weight 1 m of length) of seamless products manufactured according to this standard. This is due to a significant number of regulated for the production of steel. For the manufacture of seamless products in accordance with GOST 9941, 20 corrosion-resistant general-purpose alloys can be used.

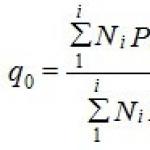

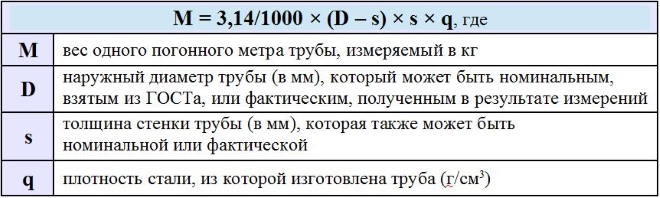

To determine the specific gravity of a pipe of a specific size, GOST proposes to use the following formula:

M \u003d 3.14 / 1000 * (D - s) * s * q, where

M - weight of 1 m of the product in kg;

D - nominal (from GOST) or actual (measured) outer diameter of the product, mm;

s - nominal or actual pipe wall thickness, mm;

q is the density of the alloy from which the product is made, g / cm 3.

GOST 9941 gives densities for all steel grades used. The alloy 12X18H10T the value of this characteristic is 7.9 g / cm 3.

To calculate the mass of pipes made of this steel with a diameter of, for example, 50 mm and with a wall thickness of, say, 4 mm, we first determine the specific gravity according to the formula:

M \u003d 3.14 / 1000 * (50 - 4) * 4 * 7.9 \u003d 4.56 kg.

The total weight of all pipes is obtained by multiplying their total length by the calculated specific gravity. One product of a standard length of 7 m will weigh: 7 * 4.56 \u003d 31.92 kg

3 Main technical requirements, characteristics and features

The chemical composition of steel 12X18H10T used for the manufacture of pipes must comply with that specified by GOST 5632. The sulfur content in the alloy intended for the production of products to be welded (this is indicated in the consumer’s order) should not be higher than 0.02%. It is allowed to produce pipe rolling from steel having microadditives of rare-earth metals.

Pipes GOST 9941 in the manufacture must be subjected to heat treatment. At the request of the consumer, the products are produced thermally untreated and without surface clarification. In this case, the norms of curvature and mechanical properties of the pipes are established by agreement of the customer with the manufacturer.

The mechanical properties of products made of 12X18H10T alloy are among the best. So, for them, the minimum value of the yield strength regulated by GOST 9941 is at least 22 kgf / mm 2 (216 MPa). The yield strength is a material parameter characterizing the magnitude of the stress, upon occurrence of which the strain in it continues to propagate and grow without a subsequent increase in load.

The temporary resistance of these pipes to rupture of not less than 56 kgf / mm 2 (549 N / mm 2), and the relative elongation of not less than 35%. At the request of the customer, the products are tensile tested at 350 ° C and they must pass this test.

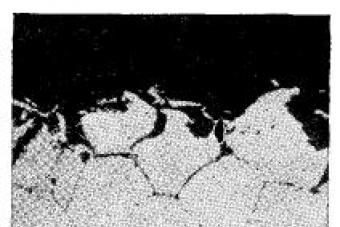

The inner and outer surface of the pipe rolling GOST 9941-81 should be free of sunsets, flaws, cracks and captivity. The elimination of defects may be carried out by local cleaning, boring and turning, local or continuous grinding, provided that as a result of the work performed, the wall thickness and / or pipe diameter are not exceeded to the limit minus deviations regulated by the standard.

The surface of the rolled pipe must be light. Matte with a gray tint is acceptable, if this is due to the method of production of the product. It is allowed to produce pipes without etching after heat treatment in a vacuum or protective atmosphere with the presence of tint colors on the surface.

At the request of the customer, pipes made of 12X18H10T alloy must withstand a flattening or distribution test in accordance with the standards established for this by GOST 9941. In addition, at the request of the consumer, the product is tested for its ability to withstand hydraulic pressure.

At the request of the consumer, which must be indicated in the order, products made of 12X18H10T alloy are made resistant to intergranular corrosion. Pipes manufactured without the use of heat treatment are not tested for distribution or flattening and tested for their susceptibility to intergranular corrosion.

4 Comparison with 12X18H10T seamless pipes produced in accordance with GOST 9940-81

Seamless products are also made from 12X18H10T steel according to GOST 9940-81. It applies to hot-rolled pipe products made from corrosion-resistant general-purpose alloys.

In contrast to GOST 9940 discussed above, they are manufactured with diameters (outer) of 57–325 mm and with a wall thickness of 3.5–32 mm. The standard maximum length of these seamless products is 3–8.5 m. Pipes are manufactured with precision and high accuracy in terms of manufacturing accuracy. Other geometric dimensions and physico-mechanical properties, which are described below, determined for pipes 12X18H10T GOST 9940 and other tolerances for wall thickness, diameter and curvature.

The chemical composition of steel seamless products of this standard has the same requirements as those produced in accordance with GOST 9941. And their mass is calculated by the same formula. The requirements regarding the ends and surface of the pipes are identical. Products are manufactured in accordance with the submitted order by heat treatment or without heat treatment and resistant to intergranular corrosion. At the request of the customer, the pipes are subjected to the same tests as those produced according to GOST 9941, and using similar methods and conditions for their implementation.

Here the only difference is that GOST 9940 their heat treatment is not a prerequisite for achieving the required physical and mechanical properties and conducting the necessary tests. After all, the method of manufacturing these products already requires the necessary heat treatment, which can not be said about the cold and heat-deformed products of GOST 9941.

The main difference between the pipes GOST 9940 and 9941 in mechanical properties. This is due to precisely different methods of their manufacture.

Hot-deformed have greater flexibility and ductility, but are significantly inferior to cold and heat-deformed ones in terms of strength and resistance to the physical impact exerted on them. So, the pipe 12X18H10T of GOST 9940 has a temporary tensile strength of at least 54 kgf / mm 2 (529 N / mm 2), but the elongation is not less than 40%. GOST 9941 products have 56 kgf / mm 2 (549 N / mm 2) and 35%, respectively.

In addition, for hot-deformed pipes 12X18H10T with a ratio of diameter to wall thickness equal to or less than 8, a reduction in tensile strength by 2 kgf / mm 2 (19.6 N / mm 2) is allowed. GOST 9941 products must withstand the rated load, regardless of the geometric parameters of its cross section. Only the yield strength of hot-deformed pipes is the same - 22 kgf / mm 2 (216 MPa). But this is due to the fact that the same stainless alloy is used for the manufacture - 12X18H10T.

Due to the greater strength, GOST 9941 pipes are manufactured with smaller wall thickness and diameters than products of standard 9940. If, for example, products with a diameter of 273 are compared, cold and heat-deformed pipes are produced with walls of 3–14 mm, and hot-deformed pipes - 11–20 mm .Accordingly, the fields of application of products of GOST 9941 and 9940 are somewhat different. The first is used where high strength of the pipeline or product is needed with its relative lightness, and the second, when the installation and operation of a stainless network or part is more important than the flexibility and ductility of the pipe from which they are made.

5 What is the secret of the prevalence of 12X18H10T pipes - the main characteristics of the alloy

Seamless pipes from 12X18H10T are used more often than those made from other stainless alloys, and in a wide variety of industries and industries, transport, utilities, as well as households and so on. This versatility is made possible by the properties of the metal. The high prevalence of 12X18H10T products, specifically GOST 9941, is also due to their physical and mechanical characteristics. But the latter also depend on the properties used for the manufacture of the alloy.

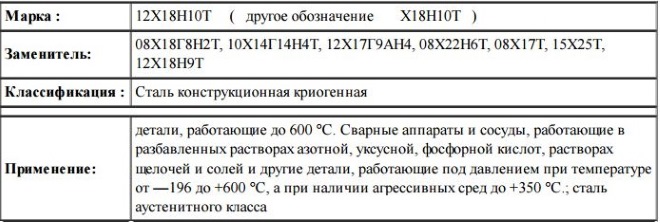

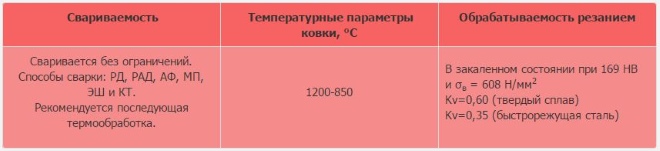

12X18H10T refers to nickel chromium. As mentioned above, the chemical composition and properties of this metal are regulated and described in GOST 5632, which applies to wrought alloys intended for use in corrosive conditions, environments and under the influence of high temperatures.

In addition, it is remarkable for welding by all types of automatic and manual welding, and also has good manufacturability during its plastic deformation in the hot state. In the cold, it allows a sufficiently high degree of plastic deformation.

6 What technical characteristics and application of pipes provide alloy properties

Due to the first and, besides, the predominant property of 12X18H10T steel, pipes from it are resistant to chemical and electrochemical corrosion (soil, atmospheric, salt, alkaline and acid), as well as intergranular corrosion, stress and others. This alloy has the ability to passivation in an aggressive environment, which provides it with a sufficiently high immunity to its effects. So, an indicator of the anticorrosion properties of steel 12X18H10T can serve as its resistance to:

- sulfuric acid (100 percent), heated to 65 about C;

- 65% nitric acid solution heated to 85 ° C;

- 80% - heated to 65 ° C;

- 40% phosphoric acid solution heated to 100 ° C;

- mixtures of sulfuric and nitric acids (70% + 25% and 60% + 10%), heated to 70 about C.

In addition, this alloy is highly resistant to solutions of various organic acids - citric, acetic, formic and others, as well as in strong alkalis - NaOH and KOH. Therefore, it is recommended to use 12Kh18N10T pipes as corrosion-resistant for the manufacture of various welded fittings in a wide variety of chemical and other industries.

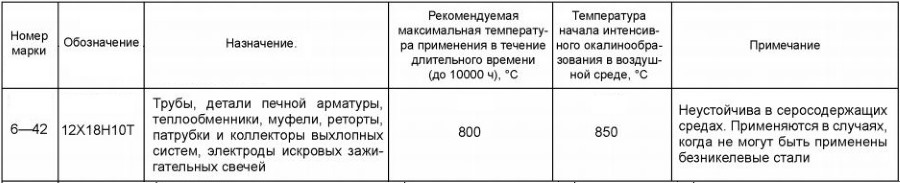

The heat resistance of steel ensures the resistance of the surface of pipes operating in light or unloaded condition to chemical destruction in gas media heated to temperatures above 550 ° C. For 12X18H10T, the maximum recommended application temperature over a long period of time - up to 10,000 hours - is 800 ° C. Intensive scale formation on the surface of this alloy pipe in air begins at 850 ° C. However, 12Kh18N10T steel is unstable in sulfur containing media.

In accordance with the heat resistance characteristics, pipes made of 12X18H10T are recommended to be used as heat exchangers, parts and assemblies of furnace fittings, retorts, muffles, electrodes of incendiary spark plugs, manifolds and nozzles of exhaust systems. In addition, they are used when it is impossible to use products from nickel-free alloys.

The heat resistance of steel with sufficient heat resistance ensures the ability of the pipe to work for a certain time under the influence of high temperatures in the loaded state. For products made of 12X18H10T, the recommended operating temperature is 600 ° C. Under this condition, the pipe service life is estimated to be very long, that is, the time is much longer than 10,000 hours (usually 50,000-100,000 hours). In accordance with the characteristics of heat resistance, products from 12X18H10T are recommended to be used as parts and pipes of exhaust systems, as well as other products operating in the modes for which the alloy is designed.

Of course, there are steels that have higher rates compared to 12X18H10T. But they have only one or two characteristics at the proper level, while others do not allow their use in the corresponding field of application - low corrosion resistance or heat resistance with heat resistance. Or in these alloys the content of alloying elements is higher. Therefore, their production and pipes from them are more expensive. As a result of this, as well as in a number of cases, based on the chemical composition of such steels, products from the latter are, as a rule, intended for narrower and specific applications in especially difficult working conditions. That is why pipes from 12X18H10T are the most common.

In addition to the above methods and applications of pipes from this alloy, the following should also be indicated. They are used in: vessels, apparatuses and pipelines operated under pressure at temperatures from –196 to +600 ° C, and in aggressive environments - only up to +350 ° C; petrochemical, food, cryogenic, pharmaceutical and chemical industries; automobile, aircraft, shipbuilding and mechanical engineering; cold and hot water supply systems (although this is not cheap); as a variety of designer decorative elements and much more.

Interstate Standard GOST 9941-81 regulates the assortment, technical requirements, acceptance rules, test methods, labeling, packaging, transportation and storage seamless pipes cold and heat deformed from corrosion resistant steel general purpose.

Assortment

According to GOST 9941-81, seamless stainless pipes are made with a diameter of 5 before 273 mm with wall thickness from 0.2 to 22 mm. The table below shows the maximum possible length for each size. The outer diameter is indicated in the first column, wall thickness in the header.

| Diameter | Maximum length with wall thickness | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.5 | 1.8 | 2 | 2.2 | 2.5 | 2.8 | 3 | 3.2 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | 11 | 12 | 14 | 16 | 18 | 20 | 22 | |

| 5 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||||||||

| 6 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||||

| 7 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||||

| 8 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||

| 9 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||

| 10 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 11 mm | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 12 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 13 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 14 mm | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 15 mm | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 16 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 17 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 18 mm | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 19 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 20 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 21 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 22 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 23 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 24 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 25 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 27 mm | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 28 mm | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 30 mm | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 32 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 34 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 35 mm | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 36 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||

| 38 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 40 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 42 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 45 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 48 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 50 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 51 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 53 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 54 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 56 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 57 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 60 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 63 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 65 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 68 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 70 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 73 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 75 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 76 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| {!LANG-8f1802253900a4b99b949d3c035aaeec!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| {!LANG-82bc054b1861095840f93fde6fd6f83f!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| {!LANG-363a3592c7ba43b9a7a56f674c0020f3!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| {!LANG-105fb9d67a2738700daeaf71d63690d8!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| {!LANG-8099ff966af6cce0483583a528e6508d!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| {!LANG-776a5f3f828d94d584ce60c5055c8c27!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| {!LANG-904211556dd59cfbdcab78c733765c9b!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| {!LANG-742e92b25d738a69f7da120e0cf907f2!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| {!LANG-cc4c30ea65e6f91ddef72ae6ffd9030d!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| {!LANG-f5eb90f1860c0fe04c44ff2c26d6f535!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| {!LANG-ecf2ffdfd62491404081b6c7a3040935!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| {!LANG-448cca8ef12bfab14c4b59f6e353cd29!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| {!LANG-c61bc133cb04003c72fec99a7c209750!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| {!LANG-6afa37a0e5e913a9a8d6fb4ba00f32ea!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| {!LANG-e9e2fd63e2496c6564d71b103d80d927!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| {!LANG-c9963f5173195185d700a776827aa43e!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| {!LANG-65f94b1412e4c45a1ad8a314ec700509!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| {!LANG-950e6a0ace4f61ee3ba4b5ecc93c6291!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| {!LANG-4dda3e935bfadaf18bc219d53bdf9b7e!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| {!LANG-e3bbdccb880ca6555f0540700895b013!} | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| {!LANG-f0f49f3abd33241fdb926f816f08e1e8!} | 6.5 | 6.5 | 6 | 6 | 5.5 | 5.5 | 5 | 5 | 5 | 4 | 4 | |||||||||||||||||||||||||||

{!LANG-6f68901ffed7a6f1e93de12fa94553b0!}

{!LANG-d27f40739b9e2390532377d8f59ce452!} {!LANG-20249932ef2f94057cde77d15874e12f!}{!LANG-f4d5047d7f78de768ffafe67365fa931!} {!LANG-ac5761c0f4c8ec9095002674ba6118e0!}{!LANG-6198aa900af947c0a648f91e0464d9fa!}

{!LANG-2144f0a993807d98df8b7f2f72e5428f!}

{!LANG-4df2b5454e7cec4004048f40570ed0ec!}

{!LANG-96980d04aeef270e8a3e871bb8f047a0!}

| {!LANG-a1483979c017eafd65b0d7ac7294c0eb!} | {!LANG-a285c179492755db0ae0a6dc753e54f0!} | ||

|---|---|---|---|

| {!LANG-1eec5d34d4a116c9e677b12054e7cbf5!} | {!LANG-76c5b4c9464b650d24ae6c44e458a30d!} | {!LANG-b6f74918389972e4cf68107f8906a16a!} | |

| {!LANG-814e8d15ee5cfeb0319197bb9fb9e459!} | |||

| {!LANG-b9538cacdd3fea14d21f6cb3402cac5d!} | {!LANG-b9b5f0459ab6c081979d878c909a8493!} | {!LANG-67fd8ba79191c66865f408aadf3226c6!} | {!LANG-0aec7880543228587b66893f73913aef!} |

| {!LANG-755da82d8b312c631f4e216d1b6be1a2!} | {!LANG-7d9e46d755dc2c73e2daf687e3aad7fb!} | {!LANG-b9b5f0459ab6c081979d878c909a8493!} | {!LANG-67fd8ba79191c66865f408aadf3226c6!} |

| {!LANG-0e8add5dd1a06b3bfce2555f096c8a42!} | {!LANG-f5bb56c46d24d08fa88ddff766aeb664!} | {!LANG-41e1f5b7b7dd5f054cee2ad34434d7d6!} | {!LANG-011af13f62131c8c4bceba01b708f2a3!} |

| {!LANG-d177743055febe9bf39f63976c589bd6!} | {!LANG-41e1f5b7b7dd5f054cee2ad34434d7d6!} | {!LANG-41e1f5b7b7dd5f054cee2ad34434d7d6!} | {!LANG-011af13f62131c8c4bceba01b708f2a3!} |

| {!LANG-d5cc59c46e88c54ddba2070b4375337c!} | |||

| {!LANG-4371e5c03979e79e3ee35ac718a5a050!} | {!LANG-bbbd7e2b1826e9875227fddd9806648c!} | {!LANG-aa165af1d0605a55721a8fe2a709efb0!} | - |

| {!LANG-22b8f2b358502f8ad9644c31fd950d08!} | {!LANG-b25e960a3ee7bfd4c104c516141c2c51!} | {!LANG-bbbd7e2b1826e9875227fddd9806648c!} | - |

| {!LANG-943059dead997379a86325b4961f546d!} | {!LANG-273391101341856f180a3abedef61690!} | {!LANG-b25e960a3ee7bfd4c104c516141c2c51!} | - |

| {!LANG-fae13edc309e8713a25c8d8ce4f5b72e!} | {!LANG-0aec7880543228587b66893f73913aef!} | {!LANG-273391101341856f180a3abedef61690!} | - |

| {!LANG-76d101725d47e6dd763df2455516dd35!} | +12,5% -15% | {!LANG-70edead8adcb74dda2b8fc46a82c6b4a!} | +12,5% -10% |

| {!LANG-da4e7e9ce6b77d22535d3eb31acc776a!} | {!LANG-70edead8adcb74dda2b8fc46a82c6b4a!} | +12,5% -10% | {!LANG-4e477d10a358a968ace70b26412cd28d!} |

| {!LANG-88133d469c6a4293bf53ffb70da6d030!} | +12,5% -10% | {!LANG-4e477d10a358a968ace70b26412cd28d!} | - |

{!LANG-638df8b96962f6c607098ee9507b862d!} {!LANG-8e64b69b8253de3e6202b2d71c3f24e9!}{!LANG-9957598d80a3110b1bea6e1a5229c345!}

{!LANG-ee355a4496a90c79bc891d67bb7e5cb1!} {!LANG-6fbe1e562f0417e5688a0d081b79f323!}{!LANG-aef1ec697c7ca4fe7a1fb00dd47889b3!}

{!LANG-e68fd6c481f091d59d18b02aa2e621be!}

{!LANG-6b1c4b94b9ab1a4de47afe806696a67d!}

{!LANG-683690bc397e4ca62886cefb84ef324b!} {!LANG-4e51c776b4dce664e6a8b5ada19384a6!}{!LANG-a3c5d44b50b385d3814af0eef29ffede!}

- {!LANG-f40e942976c44044cb523985ccda1ec4!}{!LANG-62f586a329cab5e0d0899b7b7decaf3b!}

- {!LANG-95395b751439afef50aba3668e17c317!}{!LANG-b90ff0c4e54fcfa6fc81c7f7de572643!}

- {!LANG-213408a80e4027bcb98a262f66535836!}{!LANG-4b4eebe11cef695756b4a596c8d37c0c!}

{!LANG-05e1fb50f9e43031a794e1d3861f41da!}

{!LANG-acf6b33da3ccadfe59deb90a89be3c79!} {!LANG-ab45842aa84736f26655d894a0bf3601!}{!LANG-36573223cba4481037abfc9e61ea9405!}

{!LANG-616156ba243878b83c2e7b4dce7078bb!}

{!LANG-b79782ac9b68ae62ebfd94c4f42db56c!}

| {!LANG-38bf08dffe9937338d52d2c8cd3d4c75!} | {!LANG-49a3437518cefc9696b1fdd568fa5f56!} | {!LANG-cf11480650ba7e1311f56998006cfd46!} | {!LANG-d4d864864aab3a0dbcf64ee859fbf0d3!} |

|---|---|---|---|

| {!LANG-00b5a452d5551da8e90fbc1ed02ad2e1!} | |||

| {!LANG-f340d6f44eac316fed9561914ec18c06!} | 372 (38) | 17 | 7,70 |

| {!LANG-799f7db88d4847007480acb89a97b647!} | 372 (38) | 22 | 7,70 |

| {!LANG-119df2f342cd99eb20f309aa0ee0aafc!} | 392 (40) | 22 | 7,70 |

| {!LANG-0f07dd2c247feda5ecbb211e63312b27!} | 441 (45) | 17 | 7,70 |

| {!LANG-1782d47a4d249da89cf5630e7d0e99e8!} | 461 (47) | 17 | 7,60 |

| {!LANG-12961014f9368fd4de027665e9d88419!} | 490 (50) | 45 | 7,90 |

| {!LANG-0822c1a212cb20e9ce84395f6c500331!} | 510 (52) | 35 | 7,70 |

| {!LANG-b4a1960ad47f13885c4e72f1ac2689e0!} | 529 (54) | 35 | 8,00 |

| {!LANG-79f0470dbeacfc8188cc288325eba62d!} | 529 (54) | 37 | 7,90 |

| {!LANG-d66ffa81613c40070faa04304ef1ae42!} | 529 (54) | 35 | 7,95 |

| {!LANG-a1dd2d317b839d48137e26a469a77c90!} | 529 (54) | 37 | 7,90 |

| {!LANG-d614e702d986662724fbb612ccdb3258!} | 549 (56) | 37 | 7,90 |

| {!LANG-db8768fff3930f38b9d30ef48d01765b!} | 549 (56) | 37 | 7,95 |

| {!LANG-6cc40b34a9b4f115879793414e0dd695!} | 549 (56) | 35 | 8,10 |

| {!LANG-4524112c2158f6e6ae2ff18d5bb8ac48!} | 549 (56) | 35 | 7,95 |

| {!LANG-efe5e39d4b481d1b9a58d279c5612415!} | 549 (56) | 35 | 7,90 |

| {!LANG-b9eff927733db7e2e4926fa51ccad132!} | 549 (56) | 37 | 7,90 |

| {!LANG-da7e31f04bb38bc90e9f58eff906bd0f!} | 568 (58) | 35 | 7,90 |

| {!LANG-4aa33d1470e73abc92ed970d21940766!} | 588 (60) | 20 | 7,60 |

| {!LANG-6fbe1e562f0417e5688a0d081b79f323!} | 490 (50) | 30 | 7,96 |

{!LANG-068ebc0bf506a84708b1a4a3c37e88ef!}

{!LANG-86fbf51c3267f5da7a9b5f01de81e64a!}

{!LANG-5d7ea2471d52c82e1b8912215f6fbfbe!} {!LANG-0c9386cb1bf3875fd89115b411b4378c!}{!LANG-4b7fb65bc2db2ab6c2a6051433c11b5e!}

- {!LANG-576aa055338c71e69b9d00ef3e1eb7b8!}{!LANG-7470b8b038faecb61bf0ba8dd378ef87!}

- {!LANG-d6a667f599f1a77a3ec5e1dbb9e586b7!}{!LANG-acdf5d5ea3c2f545b6e8111b471df132!}

- {!LANG-359c1d3a08c074b7d70c66b05c5ce1cc!}{!LANG-b72efa686227052123198a8fcb0eca9c!}

- {!LANG-b593df7d7a298a712ac71bead1cfceda!}{!LANG-1fb9a6ea84b12824f3b608d351a4cfe8!}

- {!LANG-3190af2154d7373c7ea42321037f3416!}{!LANG-3d4e8276af5fc125b6c4d2a8fb5caff3!}

{!LANG-ebfb5c0ca063863c07d933921c9a3d0b!}

{!LANG-0a51ca617ea06f60b08b9dd596ddfe7b!}

{!LANG-62afa6c44438ccfd5460628396c32d72!}

{!LANG-e862bb621ef6fdf2c89740849a28ebcc!} {!LANG-1a24fe828944dbd034f27860e60bf4bc!}{!LANG-c794fe320840f875be456d046bb348d9!} {!LANG-30068ca1e78de595829c53430f4a2cf4!}{!LANG-eebac873cce037591be8b2b930e68aab!} {!LANG-f8451dde2154d202c041c41f5df39714!}{!LANG-2453b8576a8c9b5fcf509d50d7a1886c!}

{!LANG-2cfb174dea666270ca207950b001acd9!} GOST 9941-81{!LANG-fbbdd3067a9247adc7a6807279efbe0d!}

{!LANG-432c80115b2d375df2a144ec240ab09a!} {!LANG-ac19e7cba79d2ef0b39701ba2d8047cc!}{!LANG-2eafeb9d4e8e018cd722e7ce8e165244!}

{!LANG-da0bd94dc97884ec7dbb66c95614ce05!}

{!LANG-7d5a0ccc2b848fc461ad0d953fd0ee15!}

{!LANG-e7d3e795e74ebbaf95654bb387df2938!} {!LANG-2413d80c4b42999585a8f6081c28ce8c!}{!LANG-7260f1c54d5ca07e48c8b9a8cb402357!}

{!LANG-f7ca99413552bac4cda019ade8033423!}

{!LANG-0313887c9b8069304a7b1ccd78b3ea31!}

{!LANG-401e8735a859e488b9946542b9e2c76f!}

- {!LANG-954668f96faaef8840b20143c3d39ddc!}

- {!LANG-e4566684f0c6042a4d5b57c62b40f4ef!}

- {!LANG-8820af51a38e5faf2884dc796a898938!}

- {!LANG-9cc32b9b6a933ad3e37c6b8daa42dded!}

- {!LANG-411d121be363580ef77cb95bffab4403!}

- {!LANG-5825aa008ec3b022408a3b4c8a283213!}

{!LANG-b652391f2b8c8f2cbf34aeab797853b9!}

{!LANG-ad7f83a9862bf31a2b4a514e7cd1c117!}

{!LANG-d555b30869a0373022860397fdc5a5a5!}

- {!LANG-4df5c886975bf643c240cd3e45cc03df!}

- {!LANG-cf52517d6aa8b3a7a7a2a022d0acb071!}

- {!LANG-f6fde6f9aeea1832f7ec03a5d94a8708!}

- {!LANG-de984074b4fad0df0a74b7964430caf1!}

- {!LANG-a2d13e77fea23f69839d6c3322f5c3db!}

- {!LANG-be657af796f781b53a89b46c946658c5!}

{!LANG-2568ec9cdfeaf5a18db549ac594068e5!}

{!LANG-c56435a5dac655a576c7c472325997e8!}

- {!LANG-2a5c60f8f0d4412c09f0c2c5d32f8021!}

- {!LANG-23aba5a140c64727e274bc51ea98f78f!}

{!LANG-edb6b9d5045d4bf2c3f868bcbe9b4b26!}

{!LANG-578dbfc4ac6658538e42a3ae219c3f7c!}

{!LANG-7eaf4d442fb8471a1d0c1ee62c8433d9!}

- {!LANG-6e0dc58df2c07cc55b8cf94edc05cf84!}

- {!LANG-487f65240482243040221e4e576786ce!}

- {!LANG-d66fec6e3da08439618a85508c646a0d!}

- {!LANG-72a7822eaf76892f63fa47679cd118ce!}

- {!LANG-4db9fa702fc4eaca8ad92467fe68f912!}

{!LANG-bb52f50ce48f8b80dc1b98368f5ba9ef!}

{!LANG-e95cf4c48e53a65b6c803962cf6c6dab!}

{!LANG-afcb298aab68298dd9c4afec97ef734f!} {!LANG-9b59cdf0449c0cd32d3c54566ea93026!}{!LANG-0804b8754b32d680044149a320791c6c!}

{!LANG-2966bfafaf3116a708c660ef707bf993!}

{!LANG-1e07a21dbc889849e6e3d93e571d583f!}

{!LANG-f5132bc51a41528539376c9844dfd76f!}

{!LANG-f090954b96ff32ec28be191bff7fabd5!}

- {!LANG-7794580db464ca9733762725b2b6fe5c!}

- {!LANG-65b25f99773ad00a8845cf206a6a4bcf!}

- {!LANG-6c886581f8077b2a5d235a18075cc069!}

- {!LANG-0fe8b531b747623751d52bcfdf870c2c!}

{!LANG-6e70e4be878d6a0cf5071a17a979482a!}

{!LANG-f0bec8e212d9538d9c4d5d900ba94bca!}

{!LANG-10690a5c490766a2d4f21683ec73e6ad!}

- {!LANG-c7d9564790ac71a5077974a682de4170!}

- {!LANG-8f3a75f741f92140aab5c9604a751b16!}

- {!LANG-1688ac5aab84f3de825839d276b258b6!}

{!LANG-4aa406b10c75656a646871e86ea6c430!} {!LANG-9b1baffcc8c60b157750cfced99720da!}{!LANG-a94350bbb7c466c2b4a08d8955e6ccd0!}

{!LANG-6031f08626d72f832798a74431ade327!}

{!LANG-8cb3ab6991aa47de9d58f0a4cff117fb!}

- {!LANG-a7a6c8d9e62a2cfd37ceeaae3b9b0835!}

- {!LANG-7dc740746ac0096a1136e669db522d62!}

- {!LANG-2bc37c18db47493149fc582c1e42cc08!}

- {!LANG-da3c8ed03d3e9891d7b2e111f2ceaeac!}

{!LANG-579dffee95237e2f7dba26530fa7b26d!}

{!LANG-ecf7d73d5dd539688f27fa8d9288bfdf!}

{!LANG-2a3631bc74b06317094e46d7ecafbdf3!}

- {!LANG-5d6a0659634ee03c6e992b6ab9399df0!}

- {!LANG-95c1e1b40693c43315ccb63ed6535234!}

- {!LANG-a29e242e1fe57e0569da8940e7283d33!}

- {!LANG-d7829197746beab55ae53ecf85479aa2!}

{!LANG-bd5b30122d9731b331085a0247d43b3f!}

{!LANG-8ca4c057f6a62c8464d6e6d361e88fb2!} {!LANG-29a575da014cba0f9316cf024ac01dd6!}{!LANG-bddf324677ca36c5c3a614a04abe2030!}

{!LANG-01fa77ef5c2158baa4af85a06645eeea!}

{!LANG-4de4934f933a971dfd6882913b3d4a1c!}

{!LANG-fe04e59c66099e6fc51ff2e7747c841c!}

- {!LANG-be96ecc70f43e12990748d0aef7cdcec!}

- {!LANG-9c0e797b8534b537e105e5f61c83002f!}

- {!LANG-2634ad241e9b7f33d9fba0e5059c9229!}

{!LANG-923c315e35b3eda09f3cf79cbf82a767!}

{!LANG-56d2eea8786005e8e8bbe10543296d9f!}

{!LANG-2e7f1046448e9bb4470da6e8157e4eb2!}

{!LANG-85d993a137c5d91fa568b4c9ab77365c!}

- {!LANG-539dd1bcf9ad01be6a920369e0370999!}

- {!LANG-c80d0dc30e83f124ff72ec7e32e55c3b!}

- {!LANG-146c67f2b8bf2a062a2865ae49fb871b!}

{!LANG-01bf02daa2d7a47f736d46ede638642e!}

{!LANG-ab848e59b0402a512d9172d0b3a0ac3f!}

{!LANG-20c363d8e1f66d4dc677fbbe7cde919d!}

- {!LANG-d15dff293491ecfb02dec2163d673862!}

- {!LANG-5d75cf75b486314802625b549331caa8!}

- {!LANG-55b781d448e492462884da70686f2c38!}

{!LANG-f1a04f0e1ff41b4239f6b8de11e600d7!}

{!LANG-4aa7ef43f5606191afd2c51f89bc9fdc!}

- {!LANG-91f91586ab5efad7a640c28ee1ebc1dc!}

- {!LANG-6f207436ea5fbb5c98dd36cacdd70b9f!}

- {!LANG-9959478cb8596cd3c9d455828387d690!}

{!LANG-427a94cbce5c722f2da94cbb3551cdfe!}

{!LANG-97ec7d6dd65d25a0d35f126b19e689a3!}

{!LANG-866a4bbc988d2eb4ab6d7fdc8b592661!}

{!LANG-d84efceb2bbe5a5b4be95a509691c3c1!}

- {!LANG-e9e97f7a4d8ab639eede8b78b12c30b8!}

- {!LANG-6f85b0aafcbe69730edcb2781f8c7612!}

- {!LANG-33083eaeb82e93a13d4165b72997a2fa!}

{!LANG-2b8312acc7bc0f0eb420faa87df1c64d!}

{!LANG-72d420de6df557643a9eee12eedf875a!}

{!LANG-c2e52cd8cf49a446d8a4f7df43941a89!}

- {!LANG-d6c656a3eb752cc73e638bbea21729b5!}

- {!LANG-9fe78820f1ce594ebde489418a8dea6b!}

- {!LANG-b595ff6742a3fe41f62d21dbc9798d6a!}

- {!LANG-8db58173b61db37c0e80bdd026651e87!}

- {!LANG-a79860b47e1c166cb7c8fa1914b8431c!}

{!LANG-33a6ef1821bf1a313edfca219f8ba76d!}

{!LANG-652a166b193e745b542f69f6d7db0578!}

{!LANG-8a39a9f6562c2116225825ff043eed8f!}

{!LANG-07b6441653628c279c06e556c272c58c!}

{!LANG-54f98a9fc89625af9209950dab33f4aa!}

{!LANG-e96a7946767012e9b76b6c647d624616!} {!LANG-da0a071ec543f1d78d54e6af585957a0!}{!LANG-06bd3a59739bc67754da5b3861b3363b!}

{!LANG-4d5f84e657f8791e0135198b92cc821b!}

{!LANG-b8f9b33344f6e24db7976a2f2c947c4e!}

{!LANG-311122e6110956c18efd4bff2be8398c!} {!LANG-291b44eb7b918ed99bd861c7f4816973!}{!LANG-0b88881a828c6e2d776d3d5ca965eace!}

{!LANG-86b5cdfe9da5f34c4f392b62e1cf6707!}

| {!LANG-ab3ed61f990958b38eca347c68fccb79!} | {!LANG-f8a2f486413567265fd9730a7a5de8c1!} | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,8 | 1,0 | 1,2 | 1,4 | 1,5 | 1,8 | 2,0 | 2,2 | 2,5 | (2,8) | 3,0 | (3,2) | 3,5 | 4,0 | |

| 8 | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - | - | - | - | - |

| 9 | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - | - | - | - | - |

| 10 | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - | - | - | - | - |

| 11 | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - | - |

| 12 | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - |

| 14 | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - | - |

| 15 | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - | - | - |

| 16 | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - |

| (17) | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - |

| 18 | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - |

| (19) | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - |

| 20 | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - |

| 22 | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - | - |

| 25 | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - |

| 28 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - |

| 30 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - | - | - | - |

| 32 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 33 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 34 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 35 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 36 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 38 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 40 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 42 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 43 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 45 | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 48 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 50 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 51 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 53 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 55 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 56 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 57 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 60 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 63 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | - | - |

| 65 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} |

| 70 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} |

| 76 | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} |

| 83 | - | - | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} |

| 89 | - | - | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} |

| 102 | - | - | - | - | - | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} | {!LANG-296d1e4e7179dd24be3a5fab3ecc8f8f!} |

{!LANG-2acc04729e00e3eae577f8ba1503917a!}

{!LANG-fa6d2463acc29b31624483a26ff79ad6!}

{!LANG-2a403ede223eaa02d78601cffff07c9e!}

{!LANG-50e79b2f5dbfc4df3c11cc92249c70f5!}

{!LANG-84363f07a55c1a836bfebcedc5fd3243!}

{!LANG-d648f9f9d2c64e7db2b42dbd335928df!} {!LANG-034b264a23e16ed7ecdb252e0b92d9f1!}{!LANG-87bdd9cb3ae615d182e1f0b868aa9e22!} {!LANG-c49d1a756d546954d76b2f268caa909a!}

{!LANG-e5ddaf1c7e44660ba6cfbac3a9e48d70!}

{!LANG-d141bdc4de27797fd6e5ac220a7c5fbb!}

{!LANG-83410d10415cc9356d3227bd9c9ec194!}

{!LANG-1079c043550a0fbad68bfb1944b7707c!}

{!LANG-66c5bd0cd3b4080dc8132ea088be9b50!}

{!LANG-96626d864f6c2481dbe6c7dd4fa17ec0!}

{!LANG-f6c139777da4a52d4559027678522f28!}

{!LANG-48661ac27d84b90f4b5b495fdcf441ff!}

- {!LANG-2ef860001744f7bb855ad4fa6a8459b1!}

- {!LANG-044306e16a7d9346294c8ed2383c2ea3!}

- {!LANG-a1d7cd86f3308da0d9fa09338737153f!}

- {!LANG-1be86ba7a4d0866dae31399757e1269e!}

- {!LANG-5f03c8b34791afa3dae10ff04ae29f08!}

- {!LANG-7440b98988de88ea3c335da503c79316!}

- {!LANG-b5c41dccd80d7905dbed79845695b18e!}

{!LANG-9989dce4e11bb2d597899348d5153c4e!}

{!LANG-09abb412eec7c656cbc9834b8a359c53!}

- {!LANG-da8198984684b92eef591a7d85d3eed1!}

- {!LANG-0ce0297f6cb1e24e329f03c3039e0ab8!}

{!LANG-a708658ab5138b0e24761288fd11a5a3!}

{!LANG-c1e241e8b4938a7a8b0d1767e70766a9!}

{!LANG-bade10db722fd8826f647ea786bc97c5!}

{!LANG-9a46412c7caf0ae6a3c8ff0d0af5488f!}

{!LANG-5b31488e6e818a75468b90dc1a062fd5!}

{!LANG-4920767abf8db731b20b0b254e121c42!}

{!LANG-04a88458ed452a0a58847919dd988409!}

{!LANG-d2f4cd522c412d82df29780be6cc9b60!}

{!LANG-6773e36b803fc5addbb02b5340368028!}

{!LANG-e09351426fd151b147ec2dcb4e6e5e1f!}

{!LANG-9eb5b6060dab5a9e4b2706375b791ca2!}

{!LANG-8a77821513fbc7daac5811171db97414!}

{!LANG-3a0705676f0b3cf73aeb83726ff4be4e!}

- {!LANG-286a2157e6aa5ebf03f3133d290785d2!}

- {!LANG-6487c0384666d6fb951bc7c89438b434!}

- {!LANG-db6bfc1f685cacabd83853df21ea238b!}

{!LANG-a1e7363aa0527129c3aa96a4b4f4f9dd!}

{!LANG-54f1e01f1629d69c8ee68403e8cc045c!}

{!LANG-efcc2aa77e61bfa833540bd6f5f3b64c!}

{!LANG-11ac458e8120ec9da91153bc7536ff2d!}

- {!LANG-4ac0e7b5afd9fb26d3670b4f03b96967!}

- {!LANG-10285369b0eea6de3f3016430d42ec8c!}

- {!LANG-a514d97eef9ace3b99e2aad0bb0975ef!}

{!LANG-e954c5aee94a2a6fea562362aca2c133!}

{!LANG-6ca5ae91dcde4355f5d92b53f4cdd686!}

{!LANG-575a87af115ff3d0fa071f21a5aad1c6!}

{!LANG-fd28591ee344024a36b7655553f6a566!}

{!LANG-150a939651ddadbe2582415512ede723!}

![]()

{!LANG-7a1f81ba83dbf245095ef46c6dc95b6f!}

{!LANG-fcd5dab01957b727b1ee6b92b2f9af73!}

{!LANG-b1c66e94776ac863818a1894db10d51a!}

{!LANG-fa897f628fe250b981e77fa47973e26d!}

{!LANG-2c0a0fd78cce5d2137212eefcea4cd34!}

{!LANG-2a259e35036028e7ea38916e2021c972!}

{!LANG-225fc08186723bca357a785c992fbd7b!}

{!LANG-3e2eaaab3f7eb86ca31f2d4cde2e437d!}

{!LANG-be5d2ed1dd3c2cb3126ba230b9d4de48!}

{!LANG-21029aa884de2b3538901cc278f9202f!}

{!LANG-8da3f6ca8f56ddd31c2334b615b7a9fe!}

- {!LANG-485c3d26d3e08276458ed79749913678!}

- {!LANG-55bfae3509cc0a157b07e093d5514f28!}

{!LANG-7f546003df301b119ce4a34616a92935!}

{!LANG-4319cefdb66a24040b803719861aa32e!}

- {!LANG-1b73ca0ec3db95031ce54545b9c89f76!}

- {!LANG-afd5e76163240ff91c64798594c7fe45!}

{!LANG-5cf2696039fff45ac65c0269cd76a5dc!}

- {!LANG-85ebeb39c4ef0a0fa6a4ce9ead069566!}

- {!LANG-832c5939895a40022f336310d228fd81!}

- {!LANG-4717fe166ce43c8beacbadcfa1c09071!}

- {!LANG-9c9fccd94060a86a3dd2d8466a721dc9!}

- {!LANG-f59ce0bfbea2882e377ce4f3038a35c5!}

- {!LANG-efd1f24083d9c85b8cc0a25accd86dfe!}

- {!LANG-f1bc4c5993bef3094d2accd69a10072a!}

{!LANG-13128b72c61bcc97076026abfb25f608!}

{!LANG-d80983a10965f7b2ea220225d6dba994!}

{!LANG-6eadc5588fe36c60274b9474f8138d4c!}

{!LANG-26116e208f1d9518473ab704e8f91e62!}

- {!LANG-0a04ee52a53e25e3f8b8e57e5af109de!}

- {!LANG-91ce76e70fe508b8766216bf850e0c94!}

- {!LANG-8b55866f4dc5e53ddd5a55b6cd34093e!}

- {!LANG-e086b6a9345a1888b7080d348b040450!}

- {!LANG-47156a528dfd18016fd891d242ec8890!}

- {!LANG-2c4023f349f1dd78870abefc3a36cff2!}

{!LANG-4a54bb1edb37a631ced6fff1fd37af38!}

{!LANG-1551f4ec63a52638e9ff22f413aa91fe!}

{!LANG-ea116b3252cf07e388f05d86cb7b271c!} {!LANG-1d348f03d076e7b8eadc888a4c0e6fb5!}{!LANG-96179313bbfa5705f1c58300d1bbd1cb!}

{!LANG-0826636bbc13a8303d0cf778ac07129b!}

{!LANG-38d27452d347610e334ea30a66264fce!}

{!LANG-10cb0942c6790a328456adf87a445a80!}

{!LANG-bbf3175e9a8447b66571aa8b1f0a3d57!} 5,00

{!LANG-0a18f451faa843399781b4846e163386!}