Most modern welding machines have a block of rectifier diodes in their design, which, in turn, provides a constant welding current. For devices using wire as a welding material (semi-automatic welding machines) this is a prerequisite. For devices that use electrodes for work, this is already an option that allows you to use almost any type of electrode for welding.

Arc classification by DC polarity:

a - direct polarity; b - reverse polarity

When working with a semiautomatic device, it is necessary to observe the polarity of the connection. So, welding with an ordinary copper-plated wire in a protective gas medium is carried out by a current of direct polarity. That is, plus is supplied to the product, and minus to the holder (direct polarity during welding). With this connection, current flows from the wire to the product, in connection with which the heating of the product is higher than that of the welding wire. And this is natural. The welded parts have a significantly larger area, respectively, require more heating to form a weld pool. A wire having a smaller area is quite easy to melt and gets into the weld place already in the form of a molten drop. The flowing current, and it flows precisely from plus to minus, captures the molten material, again contributing to the formation of a high-quality weld pool.

Judging by the comments of visitors to our site, there was a little confusion about the direction in which the current flows in the circuit. Let's try to clarify this issue!

It must be understood that the "direction of the current" in electrical engineering is more a convention adopted for drawing circuits. Traditionally, in the diagrams, it is customary to draw from plus to minus, as if the current moves from plus to minus, although the actual movement of charge carriers in most cases occurs in the opposite direction! If the conductor is metal (wire, electrode, etc.), the real charge carriers - electrons, fly from minus to plus (because electrons are negatively charged particles). If the conductor is an ionized gas or liquid with ions, then the ions fly in both directions.

When working semi-automatic without a protective gas environment, a special flux-cored (flux) wire is used. In this case, the polarity of the connection of the holder and the "mass" necessarily changes. That is, on the mass is “minus”, and on the holder plus (reverse polarity during welding). This is due to the fact that the melting point of the flux is approximately the same as the melting temperature of the metal, however, to obtain a high-quality weld, it is necessary that the flux burns and forms a small gaseous cloud in the environment of which the welding process will occur. As already noted above, the current flows from minus to plus, so the drop of the molten metal drop will be slightly lower, which will provide less heating of the weld metal, since the latter is not cooled by the shielding gas medium and the formation of the weld pool will be approximately the same as with welding in a gas environment.

Non-ferrous metals, in particular aluminum, are welded, as a rule, with a special tungsten electrode. In this case, direct polarity is usually used when welding - minus on the electrode. This type of connection allows you to get a higher temperature in the heating zone, which is especially critical for the same aluminum, since initially it is necessary to “break through” the oxide film, especially since the melting temperature of the latter is much higher than the metal itself.

Direct polarity, among other things, allows you to get a more concentrated and narrow electric arc, a deeper penetration of the metal, and, accordingly, a better weld and, importantly, use a smaller diameter of the expensive tungsten electrode, as well as reduce the consumption of at least cheap gas.

When connecting a tungsten electrode in reverse polarity during welding - with a plus on the holder - the seam turns out to be less deep. This method is good when welding thin plates - in this case there is no danger of burning the material to be welded. However, another drawback is the effect of "magnetic blast". In this case, the resulting arc turns out to be wandering and the seam turns out to be less beautiful and airtight.

Question:What filter should be used when welding with one or another electrode, for example 3 mm and 5 mm?

Answer: Here is a comparative table on the use of filters for different types of welding and amperage - on which the brightness of the welding arc depends:

Compliance of European standards with European: C3 \u003d 8 DIN, C4 \u003d 9 DIN, C5 \u003d 11 DIN, C6 \u003d 12 DIN, C7 \u003d 12 DIN, C8 \u003d 13 DIN

| Type of welding | Welding current, A | |||||||||||||||||||||||

| 1 | 2,5 | 5 | 10 | 15 | 20 | 30 | 40 | 60 | 80 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | 360 | 400 | 450 | 500 | more | |

| Manual arc | 9 | 10 | 11 | 12 | 13 | 14 | ||||||||||||||||||

| MIG, heavy alloy | 10 | 11 | 12 | 13 | 14 | |||||||||||||||||||

| MIG, light alloy | 10 | 11 | 12 | 13 | 14 | 15 | ||||||||||||||||||

| Tig | 9 | 10 | 11 | 12 | 13 | 14 | ||||||||||||||||||

| Mag | 10 | 11 | 12 | 13 | 14 | 15 | ||||||||||||||||||

| Plasma cutting | 11 | 12 | 13 | |||||||||||||||||||||

| Microplasma. cutting | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | ||||||||||||||

Question:What does direct and reverse polarity mean, where to connect the plus and where is the minus?

Answer:Direct polarity is connected to the part +, and to the electrode -, with reverse polarity, vice versa to the part -, and to the electrode +. The difference lies in the fact that more heat is generated at + than - -, therefore, depending on the specific welding task, the polarity can be switched. For example, the reverse polarity of the connection is used when welding sheet metals that are sensitive to overheating of alloy steels, stainless steel. In addition, the polarity affects the transfer of metal from the electrode to the part.

Question:I'm going to learn how to cook, how is the easiest way to do this?

Answer:It’s easiest and most comfortable to cook with direct current, it’s even easier and easier to cook with a semiautomatic device, since in it you can clearly see the arc and metal. If you take an inverter, then it is desirable that it has functions that facilitate work - fast ignition, anti-sticking of the electrode, resetting the afterburner of the arc, etc., the more adjustable functions - the more comfortable it will be to perform a number of operations, but the higher the cost of the device.

Question:When welding on the inverter, the electrode sticks, it ignites very badly after almost 10 poking into the metal, how can I stop this?

Answer:There can be many reasons: a) wet electrodes, then they must be calcined and kept in a sealed container; b) some electrodes, for example, UONII, are very sensitive to the selected current, while welders try to increase the current, which exacerbates the problem (since the rod burns faster than coating), i.e. you need to adjust the current strength - most likely to reduce it or change the polarity.

Question:What is better to buy - welding transformer or inverter?

Answer:This is a big and difficult topic, the choice depends on the specific operating conditions, manufacturer, model, forthcoming work, etc. Here are the main pros and cons of transformers and inverters.

Transformer:

Reliable, durable, allows continuous operation, easily combined with an oscillator (for example from TIG welding), insensitive to power surges, etc.

It is heavy and inconvenient for carrying, voltage and current are inconveniently regulated

Inverter:

Small, compact, light, easily adjustable voltage, current and other parameters (when the arc is not lit)

Overheating is unacceptable (therefore, operating / resting times are written for each model, depending on the mode), it is difficult to connect an oscillator (on most models), it is afraid of damp, iron dust and sawdust (and attracts them), low voltage, many models are afraid of the cold, most models cannot be twisted while the arc is running - and the lower the quality of the device, the higher the likelihood that as a result of violation of one or more rules the device will fail.

Question:How to weld a galvanized part to ferrous metal, what kind of flakes occur during such welding?

Answer:Galvanized parts must be carefully and efficiently cleaned from the galvanized layer, both at the weld point and nearby, since zinc forms very toxic compounds for combustion when burned, and zinc residues falling into the seam greatly reduce its quality.

Question:The crocodile by which I attach the mass to the corners glistens, heats up, turns black - is it possible to attach the mass better?

Answer:It is best to use a clamping clamp to connect the mass, it will provide reliable contact.

Question:Is it possible to weld aluminum parts by manual arc welding?

Answer:Yes, for this there are special electrodes for aluminum, but such welding requires a highly qualified welder, the electrodes should not be stale, mandatory preliminary heating of the parts is required. Those. nevertheless, to obtain high-quality welding, it is better to weld aluminum with TIG welding.

Question:Is it possible to weld titanium parts by manual arc welding and are there special electrodes for this?

Answer:No, it is impossible and there are no electrodes for titanium for RDS. Titanium can only be welded in an atmosphere of very high purity argon, otherwise titanium actively absorbs oxygen and in large quantities of hydrogen, as a result of which the seam will inevitably burst.

Question:How to brew holes in a thin sheet of metal?

Answer:It is better to weld a thin metal with semi-automatic wire welding, but if there is no such welding, you can weld a roller around the hole and continue to weld it and narrowing inside the hole - gradually weld it all. Also to avoid perforation thin metal You can put a copper plate under the metal and cook on the reverse polarity.

Administration Overall rating of the article: Posted: 2012.05.16

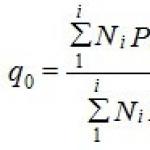

Welding Current Polarity - one of the important parameters affecting quality weld. After all, the direction of the current flow, that is, the electrons in the metal, depends on it, which affects the weld process, arc burning, the formation of the weld pool and, as a result, the quality of the welded joint.

Regarding the physical meaning, as well as the terms “direct” and “reverse”, I wrote a separate article earlier. And now I will tell you the basic principles of using the direct and reverse polarities of the welding current. And most importantly, you need to know: where "+" is, there is more heat. Accordingly, when welding on current with reverse polarity, when “+” on the electrode, it heats more than in the case of a straight line. And the part, on the contrary, heats up more when welding with current of direct polarity.

Subtleties and features

With detail, the situation is somewhat trickier. When “+” on the part, the penetration spot is wider, but the depth is not greater, or even less, than when “-“ on the part. With a “minus” on the part, the spot of the weld pool is less, but its depth can be no less, or even more than when welding with current of direct polarity. Due to this, when the details are “minus”, it turns out to be better to control the movement of the weld pool.

How to use it in practice? There are many options. Usually, the direct polarity of the welding current is used by default - especially when it is necessary to warm up and boil parts strongly. Reverse polarity is used in cases where you need to more accurately control the movement of the weld pool. For example, these are some species, especially from top to bottom. Reverse polarity welding can also help with ceiling joints and - in fact, in this case the part warms up less, and this will minimize metal runoff when performing vertical and ceiling seams and through penetration of metal during welding of a thin sheet.

The polarity of the welding current also depends on the electrodes.

Another important point is this. Not all electrodes allow the use of welding current of any polarity. For example, electrodes with the main type of coating should be welded only with a “minus” on the metal being welded. Such electrodes include, for example, UONI-13/55 electrodes. In any case, always check that the actually set polarity of the welding current is acceptable for the specific electrodes used.

Summary

So, it is important to understand that the choice of the direction of the welding current depends on the spatial position of the weld, the selected electrodes, the thickness of the metal and the personal skills of the welder. If all these conditions are met, then the seams will turn out to be high-quality, reliable and aesthetic.

And most importantly - experiment! I say this very often, because in fact, only an experiment will give you the most accurate and correct answers to your questions!

Perhaps I opened this topic a little messy, so if you have any questions, write them in the comments. And also be sure to tell us about your experience using direct and reverse polarities!

Depending on a number of factors, welding arcsupplied by DC welding can have direct or reverse polarity. In the first case, the plus charge is applied to the elements being processed, and the minus charge to the electrode. Reverse polarity during welding differs by supplying “plus” and “minus” to the part to the electrode. Details on the specifics of the methods are given below.

Process Features

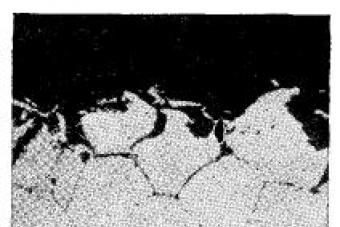

The dimensions and shape of the resulting seam also depend on the location of the poles. For example, deeper melting is possible with a direct current of reverse direction, which is due to increased heat generation at the anode and cathode.

It is important to remember - the faster the welding process is carried out, the seam width and penetration depth become smaller.

What equipment to use

The reverse direction is in demand in the work of special installations. The specificity is that the machine feeds the wire at a certain speed to the workpiece, so several types of welding can be selected.

For example, in a shielding gas environment (when argon or carbon dioxide is used), or using a powder-treated wire. The reverse directionality of the current is applicable when working with gases, the direct current - when the process is performed by cored wire (also known as flux wire).

Semi-automatic welding involves a number of process changes. Firstly, the connection of the "holder" and the "mass" is changing - on the first "plus", on the second "minus" (reverse). This is done so that the flux burns out completely, and the welding process takes place inside the gaseous cloud formed. The metal will heat up less, and splashing drops will be minimized.

The straight line is used for welding non-ferrous metals when a tungsten electrode acts as a working consumable element. Thus, an increase in temperature in the heating zone is achieved, which may be critical for, for example, aluminum.

In working with alternating current, the user's task is to change consumables in a timely manner. Professionals or advanced amateurs prefer direct current as a reliable guarantee of high-quality welding. Working with the inverter allows you to choose one of two well-known options. Forward and reverse polarity in welding are methods, each of which has its own advantages and disadvantages. The choice of direction is dictated by a number of factors, the main of which are consumables material and equipment used.

If you know other specific features of the choice of welding parameters, share information in the comments to the article.

Electric arc welding, in comparison with gas welding, has some features. This is a higher temperature, up to 5000 ° С, of the arc itself, which exceeds the melting temperature of all existing metals, and a wide variety of types and types of welding, and, accordingly, methods and purposes of its application. Arc welding varies in degree of mechanization, in the type of current, in the type of arc and the properties of the welding electrode, as well as in other parameters. In this article, I would like to consider some of the nuances of electric arc welding, depending on the polarity of the welding electrodes.

Types of welding.

By the type of current used, two types of arc welding are distinguished:

- welding by an electric arc powered by alternating current;

- arc welding powered by direct current.

In turn, DC welding is of two types:

- welding with direct polarity;

- reverse polarity welding.

Consider the features of each type of DC welding in more detail.

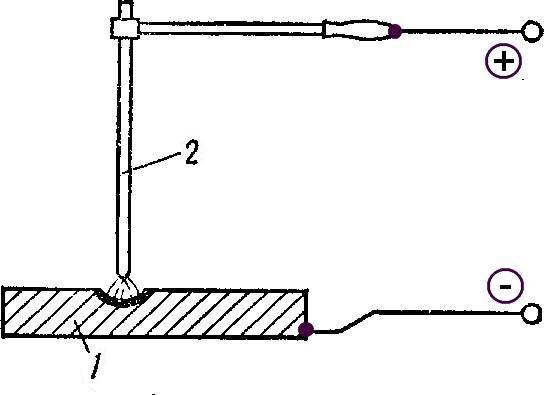

Welding with direct polarity.

By welding of direct polarity it is customary to mean welding, during which a positive charge from the welding rectifier is applied to the welded part (product), that is, the welding cable connects the welded structure to the plus terminal of the welding machine. A negative charge is supplied to the electrode through an electrode holder connected by a cable to the negative terminal.

Since the temperature at the positive pole (anode) is always much higher than at the negative (cathode), it is recommended to use direct polarity current when cutting metal structures and welding thick-walled parts, as well as in other cases where it is necessary to achieve high heat generation, which is just and is a characteristic feature of this type of connection.

Reverse polarity welding.

To conduct welding with reverse polarity current, the connection should be carried out in the opposite way: apply a negative charge from the minus terminal to the item being welded, and a positive charge from the plus terminal to the electrode.

This polarity of the welding electrodes provides a reverse direct connection situation - more heat is generated on the electrode, and the heating of the part is relatively reduced. This allows for more “delicate” welding and reduces the chance of part burning. Accordingly, reverse polarity welding is recommended to be used if it is necessary to weld thin sheets of metal, stainless steel, alloy steel, other steels and alloys that are sensitive to overheating.