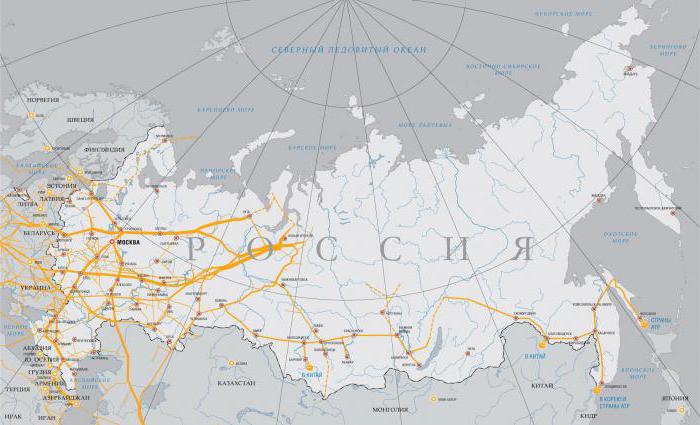

Pipeline transport carries out the movement of such important goods as oil and natural gas. Russia's pipelines have more than half a century. Construction began with the development of oil fields Baku and Grozny. Today's Card of Gas Pipelines of Russia has almost 50 thousand km of main pipelines, according to which most Russian oil pumps.

History of gas pipelines of Russia

Gas pipeline transport in Russia began to actively develop in 1950, which was associated with the development of new deposits and the construction of an oil refinery in Baku. Already by 2008, the number of transported oil and petroleum products reached 488 million tons. Compared to 2000, the indicators increased by 53%.

Every year in the Russian gas pipelines (the scheme is updated and reflects all highways) is growing. If in 2000 the length of the pipeline pipe was 61 thousand km, in 2008 it was already equal to 63 thousand km. By 2012, the main gas pipelines of Russia significantly expanded. The map displaced about 250 thousand km of the pipeline. Of these, 175 thousand km was the length of the gas pipeline, 55 thousand km - the length of the oil pipeline, 20 thousand km - the length of the oil product pipeline.

Gas pipeline transport of Russia

The gas pipeline is the engineering design of the pipeline transport, which is used to transport methane and natural Gas. Gas supply is carried out using overpressure.

Today it is difficult to believe that the Russian Federation (today the largest exporter of "blue fuel") initially depended on the raw material bought abroad. In 1835, the first Blue Fuel Mining Plant was opened in St. Petersburg with a distribution system from the deposit to the consumer. At this plant was mined gas from foreign coal. After 30 years, the same plant was built in Moscow.

Due to the high cost of construction gas pipes And imported raw materials The first gas pipelines of Russia were small. Pipelines produced large diameters (1220 and 1420 mm) and with a high standing. With the development of technologies of the field of natural gas and its prey, the size of the "blue rivers" in Russia began to increase rapidly.

The largest gas pipelines of Russia

Gazprom is the largest gas artery operator in Russia. The main activities of the Corporation are:

- geological exploration, mining, transportation, storage, processing;

- production and sale of heat and electricity.

Currently there are such active gas pipelines:

- Blue Stream.

- "Progress".

- "Union".

- "Northern Stream".

- Yamal Europe.

- Urengoy-Pomarazhzhgorod.

- Sakhalin-Khabarovsk-Vladivostok.

Since many investors are interested in the development of the oil-producing and oil refinery, engineers are actively developing and build all the new largest gas pipelines in Russia.

RF oil pipelines

The oil pipeline is the engineering design of pipeline transport, which is used to transport oil from the place of production to the consumer. There are two types and commercials.

The largest mains of the pipeline:

- "Friendship" - one of the major tracks Russian Empire. Today's production is equal to 66.5 million tons per year. The highway passes from Samara through Bryansk. In the city of Mozyr "Friendship" is divided into two plots:

- south Magistral - passes through Ukraine, Croatia, Hungary, Slovakia, Czech Republic;

- northern Highway - through Germany, Latvia, Poland, Belarus and Lithuania.

- Baltiyskaya pipeline system - This is a system of oil pipelines that connects the place of oil production with the seaport. The capacity of such a highway is 74 million tons of oil per year.

- The Baltic Pipeline System-2 is a system that binds the Friendship oil pipeline with Russian ports in the Baltic. Power is 30 million tons per year.

- Eastern oil pipeline connects the place of Eastern and Western Siberia with the US and Asian markets. The capacity of such an oil pipeline reaches 58 million tons per year.

- The Caspian Pipeline Consortium is an important international project with the participation of the largest oil-producing companies created for the construction and operation of pipes with a length of 1.5 thousand km. Working capacity is 28.2 million tons per year.

Gas pipelines from Russia to Europe

Russia in Europe can supply gas in three ways: through the Ukrainian gas transmission system, as well as through the Nord Stream gas pipelines and Yamal-Europe. In the event that Ukraine finally ceases cooperation in the Russian Federation, the supply of "blue fuel" to Europe will be carried out exclusively gas pipelines in Russia.

Methane flow diagram to Europe assumes, for example, such options:

- The "Nord Stream" is a gas pipeline that connects Russia and Germany along the bottom of the Baltic Sea. The pipeline bypass transit states: Belarus, Poland and the Baltic countries. "Northern Stream" was put into operation relatively recently - in 2011.

- Yamal-Europe - the length of the gas pipeline is more than two thousand kilometers, the pipes are held through the territory of Russia, Belarus, Germany and Poland.

- "Blue Stream" - the gas pipeline connects Russian Federation And Turkey for the bottom of the Black Sea. Its length is 1213 km. Design capacity is 16 billion cubic meters per year.

- "Southern Stream" - the pipeline is divided into sea and ground sections. The sea plot passes along the Blossom of the Black Sea and connects the Russian Federation, Turkey, Bulgaria. The length of the site is 930 km. The land plot passes through the territory of Serbia, Bulgaria, Hungary, Italy, Slovenia.

Gazprom stated that in 2017 the price of gas for Europe will be increased by 8-14%. Russian analysts argue that the volume of deliveries this year will be more than in 2016. The income of the Gas Monopoly of the Russian Federation in 2017 can grow by 34.2 billion dollars.

Gas pipelines of Russia: Import schemes

The countries of the near abroad, with which Russia supplies gas, includes:

- Ukraine (sales amount is 15.5 billion cubic meters. M.).

- Belarus (19,6).

- Kazakhstan (5,1).

- Moldova (2.8).

- Lithuania (2.5).

- Armenia (1.8).

- Latvia (1).

- Estonia (0.4).

- Georgia (0.3).

- South Ossetia (0.02).

Among the countries of far abroad, Russian gas uses:

- Germany (delivery volume is 40.3 billion cubic meters. M.).

- Turkey (27.3).

- Italy (21.7).

- Poland (9,1).

- United Kingdom (15.5).

- Czech Republic (0.8) and others.

Gas supply to Ukraine

In December 2013, Gazprom and Naftogaz signed an addition to the contract. The document describes a new "discount" price, a third less registered in the contract. The contract entered into force on January 1, 2014, and must be extended every three months. Due to the debts for Gazprom gas, he canceled a discount in April 2014, and from April 1, the price rose, reaching $ 500 per thousand cubic meters (the cost at a discount was $ 268.5 per thousand cubic meters).

Planned to build gas pipelines in Russia

Map of gas pipelines of Russia at the development stage includes five sites. The project of "Southern Flood" between Anapa and Bulgaria is not implemented, "Altai" is being built - this is a gas pipeline between Siberia and Western China. The Caspian gas pipeline that will supply natural gas from the Caspian Sea, in the future should pass through the territory of the Russian Federation, Turkmenistan and Kazakhstan. For deliveries from Yakutia to the countries of the Asia-Pacific region, another route is built - "Yakutia-Khabarovsk-Vladivostok".

The main gas pipelines are complexes of structures that are intended to move flammable gases from their prey or production to end consumption places.

Classification of main gas pipelines (according to working pressure):

- І class - high pressure, more than 25 kgf / cm2;

- ІІ class - medium pressure, 12-25 kgf / cm2;

- III class - low pressure, up to 12 kgf / cm2.

In addition, gas pipelines can be:

- trunk - built in order to transfer gas from mining sites to end items (as mentioned earlier);

- local - with the aim of collecting natural gas to distribute it in cities, industrial enterprises.

Russia's main gas pipelines have different performance. It is determined based on the data on the fuel and energy balance of areas of the areas where the creation of a gas pipeline is assumed, the determination of the rational annual amount of gas, taking into account the use of the resource for the perspective of years after the start of operation of the main gas pipeline.

Typically, the performance of the main gas pipeline is characterized as the amount of gas that enters it for the year. Basically, productivity will have an indicator less due to the uneven use of gas on weeks or season of the year. This is due to fluctuations in the temperature of the external air and the mode of operation of gas users. This is due to fluctuations in the temperature of the external air and the mode of operation of gas users.

To increase the performance of the main gas pipelines in different parts, Lupings can be built. In the case of setting stationary modes of gas pipelines during solving some tasks, the location of the lupulation does not matter.

A significant increase in the performance of the gas pipeline can be installed on compressor stations of centrifugal superchargers with a gas turbine or powerful electric motors. The first type of machines uses fuel in the form of gas, namely transportable gas. The burning of such gas in the combustion chambers of these devices does not represent a large problem compared to the use of liquid fuel.

In order to fully characterize the process of automatic control of the performance of trunk gas pipelines, it is not enough to determine the stability of the system. An important part of this process is the analysis of unspecified processes in systems that are engaged in long-range gas transport.

This is one of the main factors that affects the selection of a certain system of automatic control of the performance of objects. The flow of transients in gas pipelines should not be carried out arbitrarily. Transient processes in automatic control systems usually have a decaying character.

During the calculation and study of the dynamics of productivity control processes of main gas pipelines, the researchers deal with inertial processes, which are obliged to their specificity of the moving gas flow through the pipeline; On the other hand, low-inertion processes generated by the effects of the masters of moving elements of compression devices. Taking to attention the complexity of this automated complexIt is quite acceptable to consider the influence of these factors of different orders separately.

The management of the Russian main gas pipeline is usually carried out by the state company, which monitors the state of the entire system and hires qualified workers. It also monitors the regular improvement in the level of qualifications of the latter.

Designations for gas pipelines

The signs of the main gas pipelines of Russia are used for the arrangement and equipment of all the necessary elements of the main gas pipeline in such a way, in which all the safe conditions of its operation and operation are observed. Signs perform warning and information functionsAnd also ensure the visual recognition of the main gas pipelines, determine the location of the yield of the gas pipeline when performing any work in its security zone. Different signs and their designations can also be used.

Such gas pipelines of Russia are marked with the help of the "Consolidation of a gas pipeline route on the ground." The signs of the main gas pipelines are set to bind the gas pipeline on a certain locality, to indicate dimensions security zone The main gas pipeline, and even - the depths of its location from the earth's surface.

This sign looks like a column, which is equipped with two posters: The first displays information about the width of the zone, which is guarded, the place of breaking and the additional technical parameters of the gas pipeline it is installed vertically.

The second poster is used to visually search and determine the desired areas from the air, and is installed at a low angle to the land plane, not more than 30 degrees. It is marked with a distance in kilometers along the highway of the entire gas pipeline.

Project creation

The design of Russian main gas pipelines can be divided into several different directions. This is the creation of projects and the design of gas pipelines, and other similar tasks.

Designing main gas pipelines has several stages. First, it is pre-project preparation. It is based on choosing the main equipment for the equipment process. This stage is important not only during the creation of the project boiler room, but also the design of the gas pipeline itself.

The design of trunk gas pipelines takes into account the amount of fuel used, the power of standard equipment, the gas pressure, which is necessary for the proper operation of gas burners and other gas consumption systems. In the presence of calculation of heat loads, they appeal to clarify the possibility of gasification.

For information on the possibility of this process, it is necessary to have a situational map of the area of \u200b\u200ba certain section of Russia - it is very important to design the main gas pipelines. All conditions must comply with SNiP standards.

The location of any gas pipeline near the object, which is planning to gasify, does not mean that the punch point will be precisely to this gas pipeline. The punch point for a potential user is determined by engineers both in a gas pipeline, which is located near the object and in a similar "constructure", which is located much further, for example, a few kilometers from the gasified object.

To determine the place of the insert, a large number of factors take into account. For example, the technical possibility of providing a potential consumer with the desired amount of fuel with a certain gas pressure.

Other factors may not be provided technically when the underlying gas pipeline is inserted in the relaxation - all aspects are determined by professionals-engineers individually in each situation, according to existing cards and location schemes. Designing main gas pipelines - a complex and capacious process, which is to trust reliable organizations. They will do everything according to the standards of SNiP.

Such organizations usually easily and simply solve questions, such as connecting to a trunk gas pipeline. For this they need:

- get documents I. technical conditions on joining already existing structures;

- prepare a draft gas supply (on the basis of cards of Russia) and fully coordinate it with the necessary instances;

- making the installation of domestic and external gas pipelines;

- develop and pass the executive and technical documentation in the organization that are responsible for the operation of buildings;

- get a subscriber book.

Transitions

Transitions are two species - surface and underwater. The latter are constructed perpendicular to the axis of water flow. Provide permissible distances between laid parallel pipelines, depending on which diameter they have. The depth of the occurrence should be at least 0.5 meters from the level of the intended blur of the bottom to the surface of the pipeline pipe and no less than 1 m from the design marks.

During the construction of the transitions of the main gas pipelines in Russia, through water or waterproof areas, pipes, for the prevention of float, are loaded with special cargo. In addition, it can use solid concreting or backfilling with the help of mineral soil.

To the places of transitions through obstacles different species (both natural and artificial) impose the requirements that will ensure the reliability of the gas pipeline and its safe use in the future. Type of construction of the transition is selected based on the comparison of the indicators of several options, between which they make the choice. Cleaning the cavities of gas pipelines is carried out by washing.

Overhead transitions that build for trunk gas pipelines can be beetroot, hanging and arched. Everything will depend on the conditions of construction. They are used on transitions through small rivers, beams or ravines. A self-supporting pipe is used in the beam transition in the role of a span structure.

Hanging transitions in their structure can be flexible, saving and guided. In flexible hanging systems, the gas pipelines are attached using suspensions to one or several cables that are transferred through pylons. In savory systems, the gas pipeline can safely resist under the action of own mass and gas weight.

In the guy systems, the pipeline pipe is held in the project position due to inclined roses or rigid farms. Arched transitions are mainly used when crossing the channels. Their composition includes rigid arched structures.

Compressor stations

Compressor stations are used to maintain working pressure in them, providing gas transportation in previously defined volumes. They are built throughout the route of the gas pipeline. In the compression station, the gas is cleaned of impurities, dried, is compromised and cooled. After that, under certain pressure, it returns back to the gas pipeline.

In most cases, the compressor stations of the main gas pipelines are constructed in a block-block version. This means that the station equipment will be delivered in the form of blocks that are already fully prepared for installation. Pumping units are installed in group or individual buildings, and more special overall shelters.

Group and individual structures of compressor and pumping stations have frameworks (steel light). Walls and roofs of such buildings are performed from light two and three-layer panels. The three-layer panel has a special frame-frame, which is closed on both sides of galvanized steel sheets, asbestos cement or aluminum alloy.

Depending on the pressure performance in collectors, the compressor stations can operate according to the schemes that include one, two or even three consistently turned on the supercharger. In addition, in the process of operation, whole groups of superchargers can be used, consisting of two or three successively connected units.

Modernity

Modern Russian gas pipelines are complex structures whose use is possible only in the presence of automated control systems for complex technological processes. Operation of such systems should be based on the results of technical studies of pipelines.

Modern Russian gas pipelines with greater pressure, compared with previous generations, with voltages of longitudinal compression.

The construction of modern main gas pipelines requires the organization of large material and financial investments, since the main gas deposits are usually removed from the end consumers. In addition, during this period, it is necessary to expect an increase in the reconstruction of gas pipelines that are in operation due to the aging of elements of compressor stations and pipe parts.

If you compare the whole country with the body, then the main gas pipelines are fully entitled to be called it with a circulatory system. And, as in the usual body, the violation of such a system leads to very difficult consequences.

Back in 2-3 century BC. There are cases of natural gas use in the national economy. So, for example, in ancient China, the gas was used to illuminate and obtain heat. Gas supply from deposits to consumers was carried out according to bamboo pipes due to the pressure of the gas source, i.e. "Self". The joints of the pipes were caught by packles. Gas pipelines in a modern understanding of this word began to appear widely at the beginning of the 19th century and were used for the needs of lighting and heating, as well as for technological needs for production. In 1859, a 5 cm diameter was built in the US state of Pennsylvania and about 9 km long, connecting the field and the nearest city of Takesville.

For one and a half century, the need for gas use grew hundreds of times, and with it the diameter and length of gas pipelines increased.

Today, main gas pipelines are pipelines intended for the transportation of natural gas from areas of mining to consumption items. Through certain intervals, gas compressor stations that support pressure in the pipeline are installed on the highways. In the final point of the main gas pipeline, gas distribution stations are located, on which the pressure decreases to the level necessary for the supply of consumers.

Currently, from the point of view of efficiency, 1420 mm is considered to be the maximum diameter of the gas pipeline.

Russia

To date, Russia ranks first in the world in the explored gas reserves (25% of global reserves), and the Russian gas transmission system is the largest in the world. The average gas transportation range is currently about 2.6 thousand km in supply for domestic consumption and approximately 3.3 thousand km in deliveries to export. The length of the main gas pipelines in Russia is 168.3 thousand km. Such a length is enough to get into the land four times.

The main part of the unified gas supply system of Russia was created in the 50s-1920s of the 20th century and besides the gas pipeline system includes 268 linear compressor stations with a total capacity of 42 thousand MW, 6 complexes for gas processing and gas condensate, 25 underground storage facilities.

Today, the owner of the Russian segment of the ESG is OAO Gazprom.

On September 15, 1943, a gas pipeline with a diameter of 300 mm Buguruslan was put into operation - Pokhvistnevo Kuibyshev with a length of 165 km and a capacity of 220 million cubic meters per year. On this day, the first gas entered the Unlessyan CHP and industrial enterprises Kuibyshev. It is from this gas pipeline that the history of the development of the gas transmission system of our country begins.

Today, the largest main gas pipelines of Russia are:

Gas pipeline "Urengoy - Pomari - Uzhgorod" - The main export gas pipeline, built by the USSR in 1983 for the supply of natural gas from the fields of the North of Western Siberia to consumers in the countries of Central and Western Europe. Bandwidth - 32 billion m³ of natural gas per year (project). The actual bandwidth is 28 billion m³ per year. The diameter of the pipeline is 1420 mm. The total length of the gas pipeline is 4451 km. The export pipeline project was proposed in 1978 from the Yamburg deposits, but later was changed to the pipeline from the Urengoy field, which was already exploited.

Gas pipeline "Union" - Export trunk gas pipeline. The diameter of the gas pipeline is 1420 mm, the design pressure is 7.5 MPa (75 atmospheres), the bandwidth is 26 billion m³ of gas per year. The main source of gas for the highway is the Orenburg gas condensate field. Gas pipeline "Union" Adopted on operating on November 11, 1980. Gas pipeline "Union" It takes place through the territory of Russia, Kazakhstan and Ukraine on the route: Orenburg - Uralsk - Aleksandrov Guy - GIS "Savenka" (the border of Russia and Ukraine) - Kremenchug - Valley - Uzhgorod. The total length of the gas pipeline is 2750 km, including 300 km through the territory of Kazakhstan and 1568 km through the territory of Ukraine.

Gas pipeline "Yamal - Europe" - Transnational main export gas pipeline introduced into operation in 1999. Connects gas fields of the North of Western Siberia with consumers in Europe. The gas pipeline has become an additional export corridor that has improved the flexibility and reliability of Russian gas supplies to Western Europe (through the Yagal-Nord and Stegal gas transmission systems - Ränten).

Gas pipeline "Yamal - Europe" - Transnational main export gas pipeline introduced into operation in 1999. Connects gas fields of the North of Western Siberia with consumers in Europe. The gas pipeline has become an additional export corridor that has improved the flexibility and reliability of Russian gas supplies to Western Europe (through the Yagal-Nord and Stegal gas transmission systems - Ränten).

Takes its beginning in the Gas Transport Knot in Torzhok (Tver region). It goes through the territory of Russia (402 km), Belarus (575 km), Poland (683 km) and Germany. The final western point of the Yamal-Europe main gas pipeline is the Malnov compressor station (in the city of Frankfurt-on-Oder) near the German-Polish border. The overall length of the gas pipeline exceeds 2000 km, diameter - 1420 mm. Design capacity - 32.9 billion m³ of gas per year. The number of compressor stations on the gas pipeline - 14 (3 - in Russia, 5 - in Belarus, 5 - in Poland and one - in Germany).

"Northern Stream" - Main gas pipeline between Russia and Germany, passing along the bottom of the Baltic Sea. Gas pipeline "Northern Stream" - The longest underwater gas export route in the world, its length is 1224 km. Owner and operator - NORD STREAM AG. Pipe diameter (external) - 1220 mm. Working pressure - 22 MPa.

Russia, Germany, the Netherlands and France are involved in the project; Against its implementation, the transit countries and the Baltic countries were opposed. The objectives of the project - an increase in gas supplies to the European market and decrease dependence on transit countries.

The gasket of the pipeline has begun in April 2010. In September 2011, the filling of the first two thread was completed.

On November 8, 2011, gas supply began on the first gas pipeline thread. On April 18, 2012, the second thread was completed. On October 8, 2012, gas supplies began on two gas pipeline threads in commercial mode.

Europe

One of the longest underwater gas pipelines is laid between Norway and the United Kingdom along the bottom of the North Sea. Main gas pipeline "Langled" Connects the Norwegian gas field Ormen Lange with the British Terminal Ishington. Its length is 1200 km. Construction began in 2004, the official discovery was held in October 2007 in London.

Near East

Gas pipeline Iran - Turkey, With a length of 2577 km, it was laid from Tabris through Erzurum to Ankara. Initially gas pipeline "Tabriz - Ankara" With a capacity of 14 billion m³ of gas per year was to become part of the pipeline "PARS"That would allow combining European consumers with a large Iranian gas-bearing field "South Pars". However, due to sanctions, Iran could not start implementing this project.

Asia

Chinese gas pipeline "West East", with a length of 8704 km, connects the basic northwestern resources of the Tarim basin - the Chancin deposit, the reserves of which are estimated at 750 billion cubic meters of gas - with economically developed oriental coast of the Middle Kingdom. The gas pipeline includes one main line and 8 regional branches. The design capacity of the pipeline is 30 billion m³ of natural gas per year. Thousands of kilometers of pipes stretched through 15 regions of the provincial level and pass through various natural zones: plateau, mountains, deserts and rivers. Pipeline "West East" It is considered the largest and most difficult project in the gas industry ever implemented in China. The goal of the project is the development of Western regions of China.

Chinese gas pipeline "West East", with a length of 8704 km, connects the basic northwestern resources of the Tarim basin - the Chancin deposit, the reserves of which are estimated at 750 billion cubic meters of gas - with economically developed oriental coast of the Middle Kingdom. The gas pipeline includes one main line and 8 regional branches. The design capacity of the pipeline is 30 billion m³ of natural gas per year. Thousands of kilometers of pipes stretched through 15 regions of the provincial level and pass through various natural zones: plateau, mountains, deserts and rivers. Pipeline "West East" It is considered the largest and most difficult project in the gas industry ever implemented in China. The goal of the project is the development of Western regions of China.

Gas pipeline "Central Asia - Center"A length of 5000 km connects gas fields of Turkmenistan, Kazakhstan and Uzbekistan with industrialized areas of Central Russia, CIS countries and far abroad. The first phase of the pipeline was put into operation back in 1967. For the first time in the history of the global gas industry, pipes with a diameter of 1200-1400 mm were used. During the construction, underwater transitions of the main gas pipeline were carried out through the largest rivers of the region: AMU Daria, Volga, Ural, Oka. By 1985, gas pipeline "Central Asia - Center" turned into a multi-informing system of main gas pipelines and gas pipelines with annual bandwidth of 80 billion m³.

Gas pipeline "Turkmenistan - China" It takes place through the territory of four countries (Turkmenistan, Uzbekistan, Kazakhstan and China) and has a length of 1833 km. The pipeline construction began in 2007. The official opening ceremony of the gas pipeline took place on December 14, 2009 at the Samandepe Department (Turkmenistan). Pipe diameter - 1067 mm. The project capacity of the gas pipeline is 40 billion m³ of natural gas per year.

North America

The first and longest today American main gas pipeline "Tennessee"Built in 1944 its length is 3300 km, and it includes five threads with a diameter of 510 to 760 mm. The route passes from the Gulf of Mexico through Arkansas, Kentucky, Tennessee, Ohio and Pennsylvania to West Virginia, New Jersey, New York and New England.

The first and longest today American main gas pipeline "Tennessee"Built in 1944 its length is 3300 km, and it includes five threads with a diameter of 510 to 760 mm. The route passes from the Gulf of Mexico through Arkansas, Kentucky, Tennessee, Ohio and Pennsylvania to West Virginia, New Jersey, New York and New England.

American High Pressure Gas Pipeline "Rockies Express", with a length of 2702 km, paved its route from the Rocky Mountains (Colorado) to Ohio. The last thread of the gas pipeline was launched on November 12, 2009. Diameter 910 - 1070 mm and consists of three threads that go through the territory of eight states. The capacity of the highway is 37 billion m³ of gas per year.

South America

Gas pipeline "Bolivia Brazil" is the longest natural gas pipeline in South America. The 3150-kilometer pipeline connects the gas fields of Bolivia with the southeast regions of Brazil. It was built in two stages, the first branch of 1418 km long began in 1999, the second branch of 1165 km long began work in 2000. The diameter of the gas pipeline 410 is 810 mm. The throughput of the highway is 11 billion m³ of gas per year.

Africa

Main gas pipeline "Transmed", a length of 2475 km, paved its route from Algeria through Tunisia and Sicily to Italy, further expansion of the pipeline supplies Algerian gas in Slovenia. The diameter of the ground part 1070-1220 mm. The current power of the pipeline is 30.2 billion cubic meters of natural gas per year. The first phase of the gas pipeline was built in 1978-1983, the second stage was commissioned in 1994. The gas pipeline includes the following areas: Algerian (550 km), Tunisian (370 km), underwater transition from the African coast on Sicily Island (96 km), Land Sicilian Plot (340 km), underwater transition from Sicily Island to Mainland Italy (15 km), land plot through the territory of Italy with a separation in Slovenia (1055 km).

Main gas pipeline "Transmed", a length of 2475 km, paved its route from Algeria through Tunisia and Sicily to Italy, further expansion of the pipeline supplies Algerian gas in Slovenia. The diameter of the ground part 1070-1220 mm. The current power of the pipeline is 30.2 billion cubic meters of natural gas per year. The first phase of the gas pipeline was built in 1978-1983, the second stage was commissioned in 1994. The gas pipeline includes the following areas: Algerian (550 km), Tunisian (370 km), underwater transition from the African coast on Sicily Island (96 km), Land Sicilian Plot (340 km), underwater transition from Sicily Island to Mainland Italy (15 km), land plot through the territory of Italy with a separation in Slovenia (1055 km).

Main gas pipeline "Magreb Europe" Binds a giant gas condensate Hassi-RMel field in Algeria - through the territory of Morocco - with GTS of Spain and Portugal. From the Spanish city of Cordoba, the area of \u200b\u200bAndalusia gas pipeline through the region of Extremadura goes to Portugal. The main supply of natural gas on the gas pipeline is entered into Spain and Portugal, significantly smaller in Morocco. Construction began on October 11, 1994. On December 9, 1996, the Spanish plot began his work. The Portuguese site was opened on February 27, 1997. The total length of the gas pipeline is 1620 kilometers and consists of the following sections: Algerian (515 km), Moroccan (522 km), and Andalusian (269 km) areas with a diameter of 1220 mm, underwater plot (45 km) with a diameter of 560 mm, as well as the Portuguese section ( 269 \u200b\u200bkm) passing through the Spanish autonomous region of Extremadura (270 km) with a diameter of 28 and 32 inches.

Australia

Main gas pipeline "Dapimier Bubbery"The commissioned in 1984 is the longest pipeline of natural gas in Australia. The length of the gas pipeline, the diameter of which is 660 mm, is 1530 km. It originates on the Berroup Peninsula and supplies gas to consumers of the southwestern part of Australia.