If you have a stove or fireplace, then you know what a chimney is, and if you are just going to purchase or build such useful thing, then knowledge about the chimney and draft in it will not be superfluous for you. During the operation of the chimney, the most common problem is how to check the draft in the chimney. First, let's figure out what traction is and why it is needed.

Chimney expansion requires professional equipment, experience and knowledge. Moreover, independent action in this respect is incompatible with the provisions of the Regulation of the Minister of the Interior and Administration on technical conditions use of residential buildings. According to Art. 3 The user of premises using chimneys and flues, flue gases and ventilation ducts may repair and maintain these objects only by persons who have the qualification certificates specified in separate regulations. Self-excitation of chimneys is contrary to the provisions of building laws and may include fines.

The principle of the chimney

In order to prevent even a gram of exhaust gases from entering the living space, the chimney must have a very good draft, due to which all waste harmful substances enter the pipe.

There is a special anemometer device for measuring thrust. Its cost is quite high. Usually it is used by gas service specialists when they start checking chimneys in apartments or private houses. For individual use, buying such a device is, frankly, expensive. In addition, you can use other methods in order to determine the presence of draft in the chimney.

Therefore, it is worth entrusting this activity to a proven team with experience and the necessary certificates. Professional milling companies can be found in the contractor search service. You fill out one form, and companies come to you with specific proposals.

How much does a chimney repair cost?

The grinding process can take 1 to 3 days. We don't need to be afraid that dust will pollute all rooms. The entire ventilation grill will be sealed and secured. The cost of repairing or deploying chimneys can be very varied. Many renovations are assessed separately. However, we can highlight some fixed costs, which are as follows.

Usually, the most common paper is used for this, which is set on fire and brought to the chimney grill. If there is a draft, then the flame will deflect towards the chimney. Instead of paper, you can also use matches. (See also: )

Traction problems

In order to determine the presence of good draft in the pipe, it is not necessary to have a special device. Sometimes the problems that arise acquire such a large scale that it is not difficult to determine the complete absence of gases from the room.

Based on the above data, we can determine the estimated cost of chimney repair. Remember, however, that each assessment must be done individually. The chimney is one of the most important elements any building. It is worth taking care of this and taking care of the full efficiency of the chimneys. All repairs and repairs must be carried out immediately after the error has been noted. Delaying repairs later can increase damage and jeopardize our health.

The basis of regular visits to the chimney. If the chimney draws attention to the poor condition of the elements that are projected over the roof, this will be a clear signal of the need for repair. In many cases it is recommended to demolish upper part chimney and rebuild it. The best will be clinker bricks with increased resistance. Let's also make sure to apply a protective layer.

As a rule, the following indicates a malfunction of the outlet pipe:

- If, while heating a stove or fireplace, you look closely at the color of the flame, then you can talk about the following. Insufficient pulling force is indicated by the flame in the firebox, which has a dark red color.

- Bright, practically White color, burning fuel, on the contrary, indicates a traction of great force.

- If there is a smell of smoke in the room, then this may indicate a malfunction of the chimney and the complete absence of draft, this effect is called reverse draft. In this case, all smoke and waste products of combustion do not enter the street, but, on the contrary, into the room. (See also: )

Reasons for the malfunctioning of the chimney

Sometimes chimney repairs have to be carried out in the event of a furnace change. As a rule, it is necessary to widen the chimney and insert a special chimney sleeve into it. These actions should be assigned to a qualified team. Only make sure that professionals use high quality materials to ensure a long service life of the entire chimney structure.

Exist Various types chimneys and ventilation ducts. The selection should be done at the design stage prior to building the house. It happens that a chimney is being built, although the furnace has not yet been selected. It is not worth saving too much on the quality of materials from which we build a stove or fireplace, as well as the quality of combustible fuel. The more we invest in quality, the more we save money and hassle.

During ideal operation of the chimney, the flame in the furnace of a stove or fireplace is usually golden in color, there is no extraneous noise in the chimney, and there is no smell of smoke in the room. The reasons for the malfunctioning of the flue gas system are mainly the following:

- Errors in the early stages of design. Perhaps the chimney is insufficient in size and simply cannot cope with the incoming flow of waste materials.

- Perhaps the wrong pipe height has been selected, which can also significantly affect the operation of the chimney. (See also: )

The first two cases are relevant when, at the first start-up of the gas column or furnace, it shows that there is no draft in the chimney. And if before that you fired a stove or fireplace and there were no problems with the removal of exhaust gases, then the reasons that influenced the draft may be as follows.

Types of cables It is good to know what we are dealing with. Thus, chimneys are divided into different types due to their function, structure, location and nature of work. Because of the function, we have chimneys: vapors that serve to remove flue gases from solid fuel flue gases - they are used to discharge flue gases from gases and are fed with liquid fuel. ventilation chimneys: - supply air, which provides the air necessary for the combustion process. - exhaust - used to replace the exhaust air in the room.

Due to the design of the casing, we have chimneys: a single layer, the wall of which is, for example, brick or thick-walled steel or multilayer chimneys made of cement-fireclay tiles, the wall of which consists of several layers. On the contrary, depending on the location, chimneys are easily divided into :. internal - chimneys are carried inside the building, as a separate structure, not connected to the building or connected to the load-bearing wall and working as an external chimney - the chimney outside the building - can be connected to the building or free standing.

- Temperature difference too great.

- Blockages in the flue pipe.

- There is a lot of soot in the chimney.

- Weather conditions: strong, gusty winds or high humidity due to prolonged precipitation.

How to fix the situation

If the check of the draft in the chimney showed its complete absence or poor quality, you will have to make a certain decision so as not to be left without heat in bad weather.

We have chosen and used a well-built chimney to serve us for many years. Provided, of course, that the entire installation works correctly. To avoid this, it is recommended to clean the chimney at least once a quarter - advises. The fireplace is not a garbage collector. Do not burn furniture, rags, plastic bottles, or colored newspapers in it. Although the "fuel" is quite high in calorific value, as a result of its combustion toxic compounds and tar are formed, which are ready to settle on the inner surface of the chimney, slowly and systematically clogging it. - It is also very bad to get wet with damp wood, such as birch, explains Mr. Leszek. - Smoking with this wood causes deposition into glass soot.

In general, ideally, a special device is installed in the chimney - a chimney draft regulator. It helps maintain the pressure required by building codes in the flue gas system. This, in turn, eliminates the malfunctioning of the system as a whole. If necessary, the regulator can both reduce and increase the force of exhaust gas extraction in the pipe.

Even then, blowing out the chimney might not do much because the tools it uses will just slide like glass. Glass soot has the ability to bite and damage the brick. This is too much for a chimney that simply burns or - if the outlet is blocked - bursts. Light chimney How easy is it to check our chimney? Just take a mirror and use it to peek into the chimney. If we see the sky, the chimney is open. The chimney master has the knowledge and the right equipment.

It is also helpful to clearly state what condition the chimney is in - whether it is suitable for use or whether repairs are needed. We can only do this with a special camera. How about this coffee? Jackpots nest high. Therefore, when building a house, it is worth protecting the chimney inlet in the network. Otherwise, we can forget about the evening coffee by the fireplace, because the jackets cannot be destroyed.

So, such a device is useful for prophylaxis, but what to do when the chimney pipe can no longer cope with the load or in general, as it turned out, it was designed incorrectly. Then all that remains is to correct mistakes and do it as soon as possible.

Therefore, it is simply forbidden to use a fireplace or stove if the chimney is not working properly. Carbon monoxide gases may not be noticed at all. Sometimes the head just starts to hurt and drowsiness appears, a person can lie down for a while and inhale poisonous substances.

Each new chimney must be lifted by a chimney master. The chimney also monitors and cleans the chimneys. The ventilation ducts should be checked and cleaned at least once a year. Flue gas pipes - twice a year. Chimneys - four times a year.

We also take care of the gas installation, which we check and tighten at least once a year. The control is carried out by a person authorized to do so, and the responsibility for its implementation lies with the owner or manager of the building. Temperature and density are two important physical properties sea water that affect the calculation of the number of operated goods.

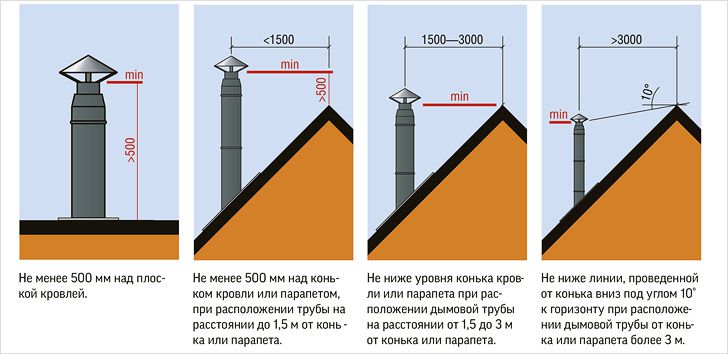

If we talk about the height of the pipe, then in accordance with the established norms, its value directly depends on the slope of the roof. If the height of the pipe does not correspond to the given parameters, it will have to be increased. According to the established norms, it is allowed to arrange the height of the pipe somewhat higher, but in no way less than the established norms.

Just be sure to take into account the fact that sooner or later the pipe will have to be cleaned. Maybe you will do it yourself, or maybe you will use the services of a specialist, it doesn't matter. Just remember that a pipe that is too high will not be able to clean properly and well.

The sea water temperature varies depending on a number of factors acting in the surface layer, the geographical location of the basin, wind, currents. For most practical situations, these two corrections cancel each other out and their effect can be neglected. The gauge will rise in the water, indicating a higher density, but the ship will rise to the water, indicating a smaller offset, with the product of the two indications not significantly altering the original data. Therefore, we can conclude that for calculating the amount of cargo for the project, the water temperature method is usually not taken into account, since this can lead to errors up to 0.35%.

Strengthening traction

If the check of the chimney draft showed its complete absence or a small value. You can also use a device such as a chimney draft stabilizer or a turbine. True, their use is limited only gas boilers... Excessively high flue gas temperature at the outlet of the pipe will cause the device to malfunction or fail.

The density of seawater varies with temperature, hydrostatic pressure and salinity. High density variations are recorded in intertidal zones and in areas where ice is melting. To accurately determine the density of seawater, measurements are taken at three levels between the bow, center and stern draft limits. The actual density or density is determined by the average reading.

The density of seawater is determined using a hydrometer. For correct definition the density of seawater, the following recommendations should be considered. The sample vessel should be rinsed with water from the test sample. The hydrometer falls slightly into the liquid and is released only after it is detected to be floating.

If we talk about stoves or fireplaces, then in order for the chimney to work correctly during not very good weather conditions. Special tips are installed on the pipe - wings. This device rotates freely so that its rear is always upwind. This position prevents wind or rain from entering the chimney directly.

Remove air bubbles that form around the hydrometer by twisting or lifting it. You read by applying meniscus correction by finding the real level. For processing, the read data are corrected with the corrections of the instruments specified in the certification of each measuring device. After reading, the instruments are cleaned and stored in their boxes to protect them from tremors.

Reading drafts is a simple operation that can be done directly or using remote drafts. Reading drafts is only possible up to the third grade sea, above which the limit cannot be guaranteed for the accuracy required for the calculation. Errors of one centimeter when reading drafts can lead to errors when estimating quantities of goods over 100 tons.

Special fans can also be used. Such devices have a built-in electric motor. Their principle of operation is as follows. Basically, they work from the wind, with strong gusts, the fan rotates, increasing the exit of exhaust gases from the pipe, if the wind flows are not strong enough, the electric motor turns on, which forces the fan to work forcibly and all harmful substances also end up on the street.

Reading is done on the embankment, in a carriage, or on a cat ladder left on the desired board. If the sea is not quiet, the fish is read several times, looking for the mean of the fluctuations. If the drawing of the main pair in the board is not readable, it is calculated using the formula.

Liquid weights on board are determined by sensing or reading graded bottles where they exist. The level of liquids in the tanks is determined by probing, according to which the volume of the liquid in the tanks is determined using the calibration plates.

The following compartments should be considered when carrying probes. Front and rear tanks. Lightweight, heavy fuel tanks and lubricants. To determine the weight of a liquid in these spaces, it is necessary to know their density, which will be measured in case of doubt about its value.

A small disclaimer, you should not run to the store and buy a new device immediately after reading the article. Before you are going to install it, you should make calculations. And already, based on the results obtained, it will be clear whether this device can be installed on your chimney.

If there is no draft in the chimney, it will be useful to check the operation of the dampers. For stoves and fireplaces, this is a kind of regulator of the force of exhaust gas removal.

The study is carried out using a hand-held probe on a specially made probe sample. The condition of the tank fluids is shown in the tables below, as well as the sailing of the vessel after the vessel has been loaded. Correctable Drafts for Drafts - Design measurements taken on rough drafts are prone to errors when the boat is pitching.

Correction of the final thrust for deformation of the ship's hull - when loading the cargo, it stops due to the uneven distribution of containers on the hulls. The body of the ship can exhibit deformations materialized in arches or contractions of the ship's corridor, depending on the distribution to the limbs or the center of the weight of the cargo.

Let's summarize

If you have a question: why there is no draft in the chimney, then first of all you should check the following. If problems with the removal of waste materials arose during the first use of the stove or fireplace, then pay all your attention to the project documentation. Check the correct calculations and dimensions of the flue pipe.

If until now you have used the stove and everything was in order, then you should first check for a blockage in the pipe. It is possible that after a long stagnation, the chimney was clogged with various types of dirt. Birds can sometimes make a nest in the pipe.

Perhaps, over time, the chimney pipe collapsed. In this regard, the normal sealing has disappeared, the outflow of the exhaust gases has become not so strong. First of all, it is worth checking the chimney, part of which is located above the roof. A pipe that is constantly exposed to atmospheric precipitation can easily collapse. This can happen if a mortar with a low cement content was used for brickwork.

Another reason, which very often leads to the problem of poor draft, is a large amount of draft accumulated in the chimney. In this case, the chimney must be cleaned. After removing soot, it is imperative to check the return flow in the chimney. If your chimney has not been cleaned of soot for many years, then after cleaning it, be sure to use products that prevent excessive settling of soot on the walls of the chimney.

Useful advice. If you have not used the stove or fireplace for a long time, and the weather has turned out with a lot of atmospheric precipitation, then it is recommended to check the efficiency of the chimney before heating. Otherwise, it may turn out that all the smoke goes directly into the room, and not into the chimney.

If you find that there is a back draft in the chimney, what can you do to eliminate it? Try to remove excess moisture accumulated in the pipe. To do this, before kindling a stove or fireplace with wood or peat, be sure to burn a couple of newspapers. Such actions will somewhat dry out the walls of the pipe and eliminate the increased humidity, so the furnace will melt easier and faster, and the smoke from the burning fuel will begin to go out into the pipe.

The use of materials is permitted only if there is an indexed link to the page with the material.

The combustion products generated during the operation of the heating boiler are carried away with the air flow through the chimney to the street. The process of flow movement through the exhaust duct is called thrust. It arises from the difference in pressure and density of cold air and heated in a furnace or boiler. Improper chimney design or blockage leads to a decrease in the intensity of the air flow, and sometimes changes its direction to the opposite. Weak draft reduces the efficiency of the heating system, and reverse draft is a health hazard. To improve the combustion of fuel in the boiler, you need to know how to increase the draft in the chimney.

Checking traction with improvised means

The efficient operation of heating depends not only on the availability of traction, the quality of the fuel also affects the combustion temperature. To exclude other factors, you need to check if air is moving through the chimney. How to check traction without a special device? To do this, you need the items at hand and simple steps:

- A burning match is brought to the combustion chamber; with normal draft, the flame is drawn into the interior of the furnace.

- A lit candle is placed near the chimney and extinguished, the direction of air movement is determined by the smoke.

- A piece of thin paper is inserted from the hole of the channel and the vibrations are monitored.

- The thrust is not only insufficient, but also excessive, while the heat is quickly carried away into the atmosphere. The strong air flow makes the flame in the firebox hum.

Lack of traction

It is important to determine why there is no traction. Decreased cravings are provoked by various reasons:

- incorrect design of the chimney duct;

- low location of the edge of the pipe relative to the roof ridge;

- deposition of a large amount of soot on the walls of the chimney or other types of blockage;

- climatic conditions - low pressure, high humidity, strong wind;

- insufficient air flow due to poor ventilation of the room;

- violation of the tightness of the channel.

Having found out the reason for the decrease in thrust, they immediately begin to correct the situation. Most of the listed defects can be repaired by yourself.

What to do

Now let's figure out how to improve traction. Design errors such as narrow pipe diameters or multiple channel bends will have to be repaired, but other cases have simpler solutions. The insufficient height of the pipe is corrected by building up, if a brick was used, then additional laying is carried out. An additional part is fixed on the metal pipe, which brings the structure to the recommended height - 5 m from the firebox.

The narrowing of the channel caused by the accumulation of soot reduces the volume of gas passed through. To clean the chimney, a simple device is made from a brush and a load tied to a rope. The device is lowered into the pipe and translational movements clear the passage.

Violation of the tightness of the brick chimney is eliminated by covering up the cracks with a solution, if necessary, transfer part of the pipe. With a sufficient size and straight structure of the channel, sleeve ceramic or metal pipe... The chimney becomes airtight, and the circular section of the duct is more efficient for exhausting gases than the rectangular one.

Note! The thin air in the room does not provide enough oxygen and has a low pressure, this provokes back draft. To increase the pressure, good ventilation is needed, it is enough to open the windows for a few minutes and the air composition will be restored.

In adverse weather, there are several ways to improve traction.

- If the outside temperature is low, the cold air creates pressure that obstructs the outgoing flow. To warm up the pipe, you can burn a little paper with it, it is also important to take care of the insulation of the structure.

- Using a strong wind to increase traction allows the installation of a deflector. This device is placed on a pipe; at the moment of exposure to air masses, a low pressure arises in it, which contributes to an increase in thrust. The diameter of the deflector depends on the size of the chimney. In the absence of wind, the device has no amplifying effect. Devices are made from of stainless steel, they are resistant to high temperature and humidity.

- A rotary turbine installed on the head has a similar effect. It spins under the influence of the wind and creates air movement in the smoke channel. The design in the form of a ball with blades protects the flue duct from precipitation and foreign objects. The turbine is installed for a gas boiler with a low flue gas temperature.

- The installation of a weather vane allows you to protect the mouth of the pipe from wind blowing. The device is rotated so that smoke is emitted from the leeward side, and the flowing air increases the thrust. reduces the likelihood of overturning the draft in the chimney. So that the moving part does not suffer from corrosion, it must be lubricated, and the weather vane is also periodically cleaned of soot.

Note! One of the reasons for the lack of traction may be a closed chimney damper (damper), if the reason is this, then after opening the air flow is normalized.

Traction stabilizer device

The traction stabilizer is a pipe with an umbrella-shaped extension. At this point there is an opening for air intake. The operation of the stabilizing device is controlled by a sensor. When gases accumulate from reverse draft or poor passage through the channel, it heats up and turns off the boiler. After eliminating the reasons for the deterioration in draft, the heater is switched on again. The stabilizer, by supplying additional air, optimizes the speed of gas movement through the chimney. It automatically changes the intensity of movement of combustion products, depending on the situation, increases or decreases traction.

Installation of forced draft

Even the minimum draft is normalized using a heat-resistant fan installed on the chimney. The device is powered by an electric motor and requires laying of a wire for power supply from the mains. This is the most effective solution for activating the movement of air mass in the chimney, regardless of weather conditions or other factors. Due to the rotation of the fan blades, forced draft... An electrical device will improve the evacuation of gases even in channels where a small pipe diameter was mistakenly chosen. Insufficient chimney height is also compensated by installing a fan. Unlike mechanical devices that only run on wind power, the electric fan is ready for use in all conditions.

Good draft is an important component of the efficient functioning of the heating system, work on its control and strengthening will ensure the stable operation of the boiler or stove.