A heating gas boiler is a device that, by means of the combustion of fuel (natural or liquefied gas), heats the coolant.

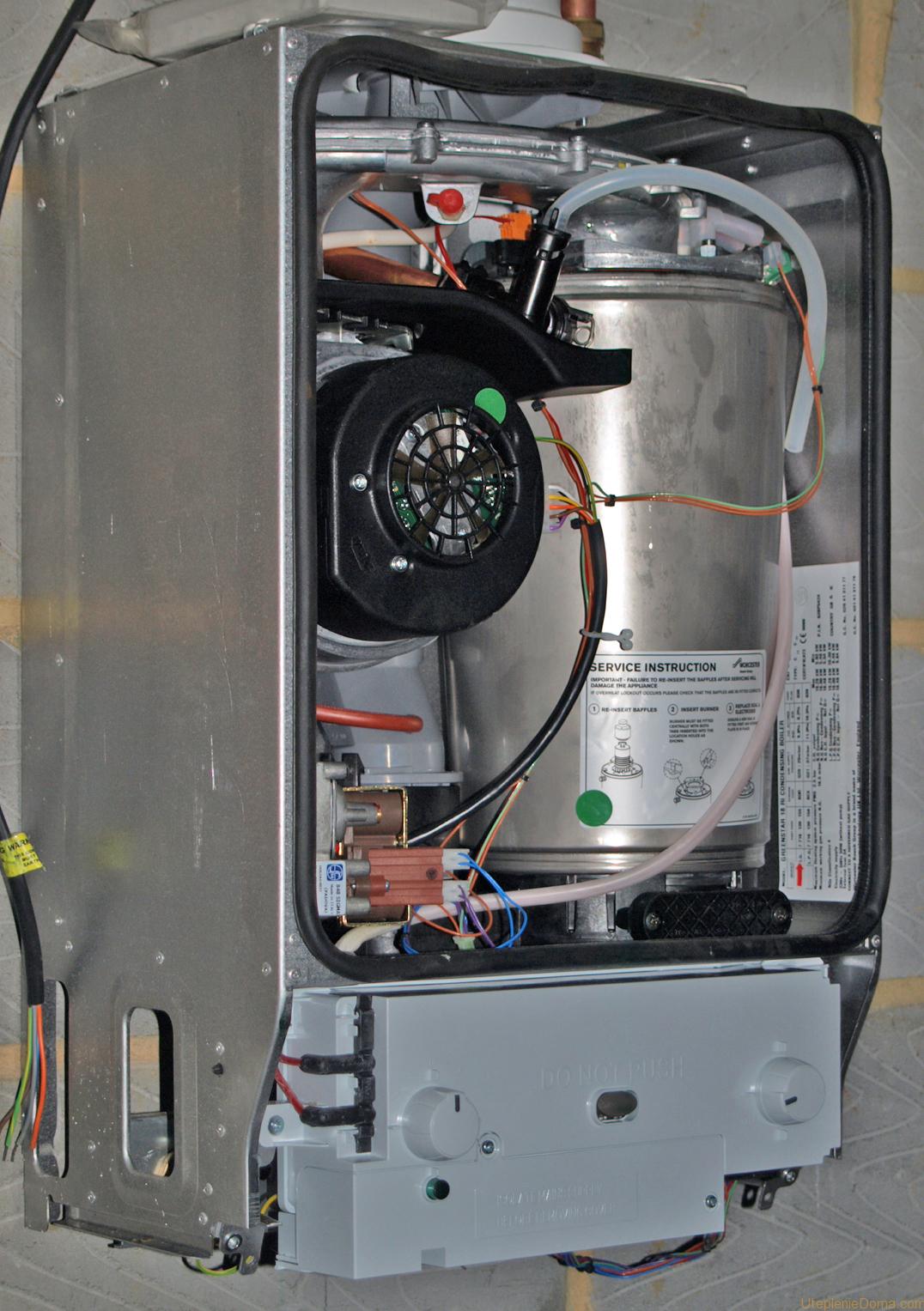

The device (design) of a gas boiler: burner, heat exchanger, thermally insulated housing, hydraulic unit, as well as safety and control devices. Such gas-fired boilers require a chimney to be connected to remove combustion products. The chimney can be either a conventional vertical or coaxial (“pipe in pipe”) for boilers with a closed combustion chamber. Many modern boilers are equipped with built-in pumps for forced circulation of water.

The principle of operation of a gas boiler- the heat carrier, passing through the heat exchanger, heats up and then circulates through the heating system, giving off the received thermal energy through radiators, underfloor heating, heated towel rails, and also providing water heating in an indirect heating boiler (if it is connected to a gas-fired boiler).

Heat exchanger - a metal container in which the coolant (water or antifreeze) is heated - can be made of steel, cast iron, copper, etc. The reliability and durability of a gas boiler depends on the quality of the heat exchanger in the first place. Cast iron heat exchangers are resistant to corrosion and have a long service life, but are sensitive to sudden temperature changes and are quite heavy. Steel containers can suffer from rust, so their internal surfaces are protected with various anti-corrosion coatings that prolong the “life” of the device. Steel heat exchangers are the most common in the manufacture of boilers. Corrosion is not terrible for copper heat exchangers, and due to the high heat transfer coefficient, low weight and dimensions, such heat exchangers are often used in wall-mounted boilers, but of the minuses, it should be noted that they are more expensive than steel ones.

In addition to the heat exchanger, an important part of gas boilers is a burner, which can be various kinds: atmospheric or fan, single-stage or two-stage, with smooth modulation, double.

To control the gas boiler, automation is used with various settings and functions (for example, a weather-compensated control system), as well as devices for programming operation and remote control of the boiler.

The main technical characteristics of gas heating boilers are: power, number of heating circuits, type of fuel, type of combustion chamber, burner type, installation method, pump and expansion tank, boiler control automation.

To determine required power gas heating boiler for a private country house or apartment, a simple formula is used - 1 kW of boiler power for heating 10 m 2 of a well-insulated room with a ceiling height of up to 3 m. If heating is required for a basement, glazed winter garden, rooms with non-standard ceilings, etc. the gas boiler output must be increased. It is also necessary to increase the power (about 20-50%) when providing a gas boiler and hot water supply (especially if water heating in the pool is necessary).

The peculiarity of calculating the power of gas boilers: the nominal gas pressure at which the boiler operates at 100% of the power declared by the manufacturer, for most boilers is from 13 to 20 mbar, and the actual pressure in gas networks in Russia can be 10 mbar, and sometimes even lower . Accordingly, a gas boiler often works only at 2/3 of its capacity, and this must be taken into account when calculating. In more detail with a table for calculating the power of a heating boiler, you can

Most gas boilers can transfer from work natural gas for liquefied gas(ballooned propane). Many models switch to liquefied gas at the factory (check these characteristics of the model when purchasing), or nozzles (jets) are additionally supplied to the gas boiler to switch to bottled gas.

Pros and cons of gas boilers:

Boiler piping- These are devices for the full operation of the heating and water supply system. It includes: pumps, expansion tanks, filters (if necessary), manifolds, check and safety valves, air valves, valves, etc. You will also need to purchase radiators, connecting pipes and valves, thermostats, a boiler, etc. The issue of choosing a boiler is quite serious, so it is better to entrust the selection of equipment and its complete set to professionals.

What is the best boiler? The Russian market of gas boiler equipment has its own leaders in quality and reliability. The best manufacturers and brands of gas boilers are presented in the assortment:

"Premium" or "Lux"- the most reliable and durable, easy to manage, the kit is assembled as a "constructor", more expensive than the others. These manufacturers include German companies

The constant increase in energy prices is forcing the population and organizations to save fuel. For efficient heating of buildings and structures, gas heating boilers are used, in which gas consumption is minimized through the use of special technologies. A non-volatile heat engineering device, in addition to saving fuel, also provides a high autonomy of the system.

The principle of operation of modern heating equipment

In the vast majority of cases, gas appliances are used for heating individual residential buildings. Main technical specifications, which is taken into account when selecting a device - efficiency. It is possible to reduce the consumption of gaseous fuel only by increasing the efficiency. Universal technological methods allow creating the most economical devices for creating comfortable conditions in the premises.

Important! Low consumption of natural or liquefied gas is achieved by using electronic system management - controllers.

The lowest gas consumption is achieved when using an electronic control system.

This circumstance makes it possible to regulate the fuel supply in the minimum amount necessary for intensive combustion. Gas boilers operate in the optimal mode for them, providing maximum efficiency. The valve controlling the supply of the gas-air mixture is closed when the specified procedure is exceeded.

The coolant circulating in the heating system is gradually cooled to a limit determined by the automatics. The valve opens and feeds the mixture into the chamber, which is ignited by a constantly working ignition device. Universal boilers operate constantly in such an intermittent mode, providing a fairly rapid heating of the coolant. The characteristic of a heat engineering device, showing the specific fuel consumption, is in modern conditions defining.

The procedure for calculating seasonal consumption

Universal coppers providing rather fast heating of the heat carrier.

The specific consumption of natural gas is indicated in the technical documentation and is expressed in cubic meters per hour. The maximum amount of fuel used during the constant operation of the heating system at home can be calculated using a simple formula. The product of the passport value of consumption per unit of time by the number of hours in a day is the desired value. However, economical boilers do not work in the mode of constant heating of the coolant.

For a more reliable assessment, correction factors are introduced. Such a characteristic of the heating modes of the building is the ratio of the duration of the equipment operation to the total time of the heating season. According to statistics, this figure is approximately one to two.

Thus, the nominal amount of fuel that a gas boiler consumes is about half of the maximum.

Types of heat engineering devices

The classification of equipment used for heating buildings occurs according to various criteria. One of important indicators is the degree of its autonomy, according to this criterion, devices are divided into two categories:

- non-volatile gas boiler operates without connection to an external network with natural circulation of the coolant;

- volatile equipment is equipped with one or more electric pumps to ensure constant movement of water in the circuits.

Versatile and economical devices are recommended for use in areas with unstable power supply. Such equipment does not turn off in case of significant voltage drops, which ensures the constancy of the temperature and humidity conditions in the premises.

Autonomous gas heating systems are widely used as universal and convenient sets of equipment for heating buildings for various purposes. In our country, the energy independence of devices is a big plus. The state of the power system in many areas does not allow providing the necessary parameters of the quality of electric current.

The specifics of the use of autonomous equipment

Non-volatile gas heating boilers are suitable for small houses.

A non-volatile gas boiler is installed in accordance with established rules. It must necessarily be at the lowest point of the system, based on this position, it is preferable to use a floor layout. The consumption of natural gas for such equipment is higher than for devices with the same technical parameters.

Heating systems without forced circulation of the coolant operate at extremely low pressure. To reduce resistance in pipelines, their cross section increases, which increases the material consumption of the circuits. This entails a significant increase in the volume of the coolant, which increases the inertia and consumption of liquefied or natural gas.

The best modern non-volatile heat engineering devices are able to provide the necessary parameters in small individual houses. They have high reliability provided that the equipment and pipelines are accurately installed. It is possible to reduce the consumption of natural gas by insulating the enclosing structures of the building from the outside or from the inside.

Advice! Gas non-volatile floor-standing appliances with a power of up to 60 kW can be installed in common areas.

Mostly they are mounted in kitchens, while the ceiling height must be at least 2500 mm, and the total area of \u200b\u200bthe room is 15 sq.m. Larger heating systems require separate boiler rooms for the installation of appliances.

Economical gas heating boilers are an effective way to equip a heating system.

A gas boiler, not equipped with electric pumps for circulating liquid in the circuits and fans for forcing air into the combustion chamber, has a slightly higher consumption of liquefied or natural gas. This limits the possibility of its use in buildings of a large area and with large height differences between the lower and upper points of the system.

A non-volatile gas boiler is good, first of all, for its high autonomy. The price for this is an increased consumption of gaseous fuel and a large thermal inertia of heat engineering equipment.

Gas, as the main heat carrier, has long been used by many residents of the country. The use of gas boilers also allows you to organize a heating system in any private house.

These designs come in different modifications, which allows you to choose the best option for each home. You can learn more about such systems by visiting certain sites, where not only the installation of boilers is considered, but also the installation technology.

We warm the house

The amount of gas consumed by the boiler directly depends on how well the building holds heat. If the walls in it are thin, the windows have gaps, all this will lead to heat loss.

Therefore, the gas boiler will constantly work to maintain the desired temperature. To reduce this figure and save the amount of gas, you need to carefully insulate every corner of the building, from the load-bearing walls to the ceiling and windows.

There are a lot of options for insulation, and choosing the best one is allowed only in accordance with the specific parameters of the house.

All gas boilers operate on the principle of temperature difference. At a certain value, the boiler can turn on or off on its own, while maintaining the desired indicator.

The gas consumption here directly depends on the coolant temperature you set. If the house is large, this also directly increases this parameter. It is possible to reduce the gas consumption in the boiler only by using additional systems that will regulate the temperature in the rooms.

For this, special thermostats are often mounted on them, allowing you to program the boiler on and off. These devices are very convenient, as they can be used to reduce the temperature in the house when you are not. The device will only operate to maintain the value you specify.

The ventilation system can also increase the flow rate, which is able to draw out hot air, while forcing the gas boiler to work and waste gas.

A good option to reduce consumption would be to lower the temperature by a few degrees. So a person feels comfortable both at +20 and at +25, then why waste energy on heating these 5 degrees.

The reduction in gas consumption in the boiler directly depends on the insulation of your building and right system temperature control in the room. This approach will significantly save on the consumption of this energy resource.

How to reduce gas consumption by up to 40% legally, see the video:

Among the heating systems offered today, gas boilers are the most in demand. This is due not only to the cheapness of fuel, but also to the reliability of the boiler, its simplicity and ease of use.

What types of gas boilers are known

According to their parameters, gas boilers can be:

- Floor and wall

- Single circuit and double circuit

- With atmospheric and ventilation burner

What are the advantages of gas boilers:

- Floor boilers are convenient, reliable and durable. Adequate space is required for their installation.

- Wall-mounted can be located in any free space on the wall.

- The boiler with one circuit is designed for heating. If there is a need for hot water, a boiler can be adapted to it in the kit.

- The double-circuit boiler is the most demanded, it gives out water for heating, and for use in the kitchen and in the shower. Essential for use in country house and at the cottage.

- A gas boiler with an atmospheric burner has a fairly low noise level and can be installed near the living area. Its design is very simple, and the cost is quite affordable. Atmospheric burner requires a constant gas pressure, with its frequent decrease, the boiler can quickly fail.

- If a ventilation burner is installed, then due to strong noise the best place for the boiler will be a basement or an extension to the house. Such a boiler has more power, and is designed for both gas and liquid fuels. It is slightly more expensive than an atmospheric burner boiler.

How to calculate gas consumption for a boiler

To find out how much “blue fuel” will be needed to heat the house during the entire heating season, you need to:

- Calculate gas consumption per day, taking as a constant that 1 kW can heat 10 sq.m. housing area. An area of 100 sq.m, respectively - 10 kW of gas per hour.

- During the day, gas consumption will be 10x24=240 kW/100 sq.m.

- For a month - 240х30=7200kW/100 sq.m. In reality, the boiler is operated at half its capacity: 7200:2=3600 kW/100 sq.m.

- For a 7-month heating season: 3600х7=25200 kW/100 sq.m. If the heating season is 5 months, then the calculation is as follows: 3600x5 \u003d 18000 kW / 100 sq.m. This is how gas consumption is calculated for any number of months.

- Now you can calculate the cash costs for the entire heating season, respectively multiplying the number of received kilowatts by the cost of 1 kW.