The laborious process of formation of the foundation can be facilitated if you resort to the arrangement of the columnar design. Conditions for installing pipes as a support and situations when a practical way is unacceptable, consider in detail. The study of the features of the construction of the foundation based on pipes from different materials will determine the appropriate way.

Nuances of the Storgent Foundation

The idea of \u200b\u200braising the foundation of the house columnally from the pipes is very attractive in terms of practicality. This method is less expensive in terms of finance and labor resources, you can do without the involvement of special equipment and work in stages. The use of an economical option is possible subject to the construction of a light construction. Among the restrictions on the arrangement of a columnary support structure, a height difference exceeds 2 m, and a problem geological situation, when there is a risk of displacement of the formation.

The depth of the foundation is changing depending on the properties of the soil and the total mass of the future facilities. Pipes from pipes are installed necessarily at one level. This applies not only to the upper part of the supports, but also the bottom edge. Equally distribute the load on the pipes of the column foundation helps the design of the framework. For wooden houses, the construction of a durable bar is more suitable, while playing the role of a mortgage crown. If the bond base is installed in the area with a low level of soil freezing as an alternative to a full-fledged belt foundation, woodwork is formed with a small deepening into the ground.

Characteristic features of a column foundation:

- Mandatory places of installation of pipes: in the corners of the building, at the points of the adjuncing or intersection of partitions.

- The distance between the supports is 1.0-2.5 m and is calculated according to the results of determining the total mass of the future building.

- The gap between the soil and high frame for lighting structures is 40-80 cm.

- Often flooded soil requires elevation of a column foundation above the ground to 1-2 m.

- The base of the house of the pipe makes it impossible to arrange the basement.

Comment! Plots where additional load is planned (furnace or fireplace, porch or terrace) are equipped with local collisters that have no bundles with a general painter.

Characteristics of support structures from various types of pipes

Pipes from the following materials can be used as a support for lightweight facilities:

- asbestos;

- plastic;

- metal;

- also applied concrete and wooden poles.

The advantages of the columnar design using asbestos pipes:

- there is no need to form a formwork, as in the case of concrete pillars;

- trench, pit and sand-gravel pillow is not required;

- installation of pipes is carried out without the participation of special equipment;

- the available value of the material reduces the estimation of the cost of building the foundation.

Disadvantages of the columnar base:

- The considerable weight of the future structures is an obstacle to the installation of pipes from asbestoscent as a support.

- The period of operation of the material does not exceed 65 years.

- Processing of pipes is carried out using protection equipment (respirator, glasses, etc.).

A columnar foundation from PVC pipes has the following advantages:

- material strength;

- not exposure to corrosion processes;

- safety for human health.

Plastic as a support is suitable only for lightweight structures (sheds, arbors and other economic buildings). A columnar foundation is formed from pipes intended for sewage.

Characteristic properties of metal supports:

- high degree of strength;

- not susceptibility to cracking;

- quick installation.

Among the disadvantages there is a gradual destruction due to corrosion, although this process is long.

Design and preparatory work

For a bar foundation, it is necessary to draw up a project, the following information will be required as source parameters:

- the nature of the soil and the features of his behavior;

- soil freezing level;

- the depth of groundwater, the probability of floods;

- the volume of precipitation in the winter;

- the total mass of the superstructure, which consists of the weight of the material for walls, overlap, roofs and other additional loads.

Focusing on the source data, determine:

- The depth of a column foundation.

- The diameter of the pipe that depends on the material used and the project load on the base.

- The number of columns and frequency of their installation.

Tip! Supports It is advisable to accommodate the following features of the soil freezing.

The construction of a column foundation begins with the markup of the terrain according to the project documentation. Well wells are formed by a manual or gasoline brown. The depth of drilling exceeds the ground freezing line by 30 cm, approximately this value is 150-180 cm. The diameter of the opening depends on the size of the pipe selected as a support for a bar foundation. Above the surface of the Earth, the posts must rise by about 50 cm. Further actions depend on the type of pipes selected.

Construction of the base of asbestos pipes

Asbestos-cement supports need additional strengthening with reinforcement rods. Approximate column sizes: Height - 200 cm, diameter - 20 cm. After its immersion in the well, the actions develop one of the way:

- mounting of metal reinforcement is underway;

- a concrete mixture is poured.

The essence of the arrangement of a column foundation in the first way:

- In the pipe are installed bars at a distance of 6-7 cm from each other.

- The approximate length of the rods is 250 cm, they should dive into the ground and perform from the pipe out of 20 cm on each side.

- The upper part of the reinforcement serves to connect with the painter.

- After registration of the carcass, the pipe is poured with concrete solution.

The drying of a column foundation lasts within one week.

The use of the second option is as follows:

- The support is poured with a mixture of concrete on 1/3.

- The pipe is lifted by 10-15 cm so that concrete at the base is growing, forming a sole for a column foundation.

- An important point is the same height of all raised supports. The reinforcement frame does not appear for their edges.

- Further, the support is completely filled with concrete, at the top fix the stud, which rises by 30 cm and serves to connect the pipe and painter.

Comment! If the soil under the columnar foundation has high flowability, before installing the supports, it is necessary to arrange a sand-gravel pillow, which is necessary to cover the rubberoid.

Prevent premature damage to the reinforcement rods due to corrosion will help their processing of protective compositions.

Supporting design with plastic

As in the previous embodiment, the process begins with the leveling and markup of the site for construction. Work is carried out using pegs and threads or rope.

The main stages of the formation of a column foundation using sewer pipes:

- The perimeter rushes a trench in which the installation points of the support are noted.

- The weight of the future structures and the characteristics of the soil determine the interval between the columns, which should not exceed 2 m.

- Before installing the plastic tube, at the bottom of the wells make a drainage pillow of gravel and sand. The waterproofing function performs polyethylene or runner.

- The recess is filled with a mixture of concrete and is left for an hour to grasp the solution.

- After the allotted period of time, a plastic tube is installed, which is pressed until it stops.

- Further, reinforcing rods are installed inside the post, which are 20-25 cm.

The grasp of concrete in the base foundation lasts 6-8 days, depending on the ambient temperature.

Features of the use of metal pipes

The formation of iron columnar design also has two options. In the first case, the installation of supports is 50 cm below the level of the drilled well. Choosing a metal pillar with a diameter of 20-25 cm not fundamentally, you can install two or three supports of a smaller thickness. In this case, the gap between the pipes is up to 5 cm.

Important! Such a method implies the formation of paintwork using a steel profile that is welded to the pipe.

The proposed algorithm for the arrangement of a bar foundation is characterized by high fixation reliability and provides the design maximum strength.

The second method requires the preliminary formation of the drainage pillow based on sand and gravel. The diameter of the columns is 15-20 cm. Since the metal support should be seamless to the walls of the well tightly, when drilling, its base decreases by several millimeters. The next step is to fill the pipe with cement and sand with solution. If the construction is planned above one floor, the need arises in the additional strengthening of the column foundation by the reinforcement frame.

After five days, after the frozen of concrete, they go to the formation of the painter. It is possible to perform it from a tree, a metal profile or in the form of a ribbon foundation. The choice depends on the severity of the entire design.

Conclusion

Column foundation - a reliable reference design for light structures. With an increase in the weight of the construction, additional strengthening measures should be provided in order to ensure strength.

Construction technologies constantly evolve. There are new techniques based on new ideas and new opportunities. One of these new building technologies is a metal foundation.

The basic idea is that steel piles and steel beams are used as carrier elements. The foundation from steel elements (see. 1) is interesting for ease of its design, easy installation. When erecting a small house, such a foundation is one of the best solutions that are technically available today.

Fig.1. Metal foundation

Erecting metal foundation

For a metal foundation, it is not required to conduct those time-consuming operations that are necessary when the "standard" foundation is erected: there is no need to dig tons of soil, seal the remaining soil, pouring, to carry out formwork (and after all, the metal formwork for the foundation itself is not Herushev). Naturally, the foundation from the metal is erected much faster. It is important that such a foundation can be erected even in winter.

Piles are used as reference elements, driven to contact with the carrying layers of the soil. Most often piles are made of steel pipes, score them to a depth of 4-6 meters. To simplify the installation of support piles and increasing the accuracy of their positioning, drilling in the required places. This is especially true for areas with rocky soil, where traditionally driven pile can meet a hard obstacle. It should be borne in mind that the pipes under the foundation must have a slightly larger diameter than the diameter of the borax (for better fixation of piles by means of friction forces).

Boy design is installed on top of the piles. The beams on the foundation, as a rule, make a box-made design of steel channels. The relationship between beams lying in the same plane is provided by bolted connections or welding. If from the aesthetic considerations, it is necessary that the foundation looks as natural as possible (it has been similar to "ordinary"), then the channel is installed at the ground level or even partially in the ground. However, the rancher for the foundation must be carefully protected from corrosion, because In the prigunt zone, these processes develop quite intensively. The susceptibility to corrosion processes is one of the main deficiencies of such a foundation, because Even high-quality processing at the construction stage will not be effective at constant humidity (intimacy of groundwater, for example). This means that after 10-15 years of operation, it may be necessary to carry out anti-corrosion processing. Taking into account the fact that steel beams will be closed, their re-processing can cause some difficulties. If the corrosion protection does not spend on time, the strength of the beams can critically decrease, the operation of the building will be impossible.

Foundation of asbestos pipes

Another relatively new "fundamental" technology is considered a column foundation from asbestos-cement pipes. A columnar foundation from such elements is distinguished by a low cost, low weight and speed of erection compared to the foundations of standard design. And most importantly, such a foundation is not subject to corrosion due to the absence of steel in external bearing elements.

Work on the foundation from asbesto-cement pipes start from positioning, so-called. "Breakdowns" on the ground. The distance between two adjacent pillars does not exceed 2 meters. If the plot is relatively smooth, then the pipes with a diameter of about 200 mm are used. With a substantial height difference (500mm and more at the length of the house), the diameter of the carrier pipes should be at least 250mm.

Fig.2. Foundation of asbestos pipes

Next follow the drilling operations. The diameter of the bera is selected by 50-100mm large than the diameter of the pipe. The depth of the wells should be about 1 meter (it is necessary to smoke below the drainage depth). Asbestos pipes for the foundation are installed in terms of the level, the emptiness between the pipe and the surrounding soil are covered with sand, they are tamped. In the center of the pipe, at a distance of about 70 mm from each other, we drive two segments of the construction fittings (see crimes.2). The edges of the reinforcement should not oppose the pipe. After that, fill in the inner cavity of the pipe with concrete. In the fresh concrete, a stud is inserted with a length of about 0.4 m with a protruding outward threaded part. At the straightest drown in concrete, you can turn the nut, for better contact. The hairpin will be a mortgage element for subsequent fixation of the bar. Further work on installation is held seven-nine days when concrete will completely freeze. At the end of the work, it is necessary to make a sinking area under the future house of gravel. It is prevented by grass growth (which is considered fire hazardous) and the erosion of the soil.

For those who are going to engage in the construction of their own home, sooner or later will be the question of which type of foundation is best to choose. Of course, those who cause the construction team and have a sufficient amount of financial resources for it, will not break their heads, how to save on the construction of the house.

The same people who are limited in financial resources will surely think about how to make a good foundation with their own hands, which will be in addition will be cheaper and reliable. Such is a column foundation from the pipes, and which will be discussed in this publication.

Advantages of a columnar foundation

Foundation columnally, despite the fact that it takes a separate place in the foundations hierarchy, something similar to the pile. This is caused by the fact that both types (piles and piles) are bought into the ground and keep the overall design of the house or facilities.

To enhance them, sometimes a special screed is used, or a monolithic type of foundation, depending on the properties of the soil on the site where construction takes place.

Its main advantages in the following:

- such a base can be used on the most complex embossed areas (slopes, irregularities that cannot be aligned);

- due to the fact that the poles are launched in the ground below the level of ground freezing, they are not exposed to shrinkage and other unfavorable moments;

- when it is created, it is not necessary to spend a large amount of funds, making a large amount of earthy and construction work, so it is possible to conclude that this type of foundation is ideal for those limited in financial resources;

- such a base is simply not replaceable if the construction is planned in those areas of the area, which are constantly adopted, or they are closer to the surface;

- this type of foundation is a find for those who are going to build a house in which the basement will be, since the base structure of the foundation is suitable for such buildings;

- the latter advantage of this foundation is that it can be easily made with his own hands by attracting the minimum number of people, as well as spending less financial resources.

But despite the presence of so many advantages, it is necessary to specify for some disadvantages. They consist in the fact that this type of base is not suitable for powerful designs and heavy buildings.

If you plan to build a capital and hard structure, it is better to combine poles together with a monolithic slab.

As mentioned above, it will be about the columnar foundation that is easy to make with your own hands. Experts recommend such a base made of pipes. Based on this, three varieties can be distinguished:

- column foundation from plastic pipes;

- a column foundation from asbestos pipes;

- foundation column metal pipes.

Each of them is easy to make it yourself, and this will be discussed.

Columnated foundation from plastic pipes

In order to create such a base with your own hands, you do not need to attract specialists, but you just need to read carefully with step by step instructionswhich consists of the following actions.

As it can be seen to make such a foundation with your own hands quite easily, the main thing is to use the above step-by-step instructions.

The base of asbestos pipes with their own hands

![]()

Asbestos pipes are also excellent material for the manufacture of a column foundation. Their peculiarity is that they are made of materials such as asbestos and cement fibers.

When choosing a foundation for the future structure, it is necessary to take into account the advantages of the selected design: stability, resistance to movable soils, strength. However, such qualities as the value of the material and the possibility of independent erection are played a large role. To save a family budget, you can build a tubular foundation with your own hands, but even a simple and accessible option requires theoretical training and skills of land.

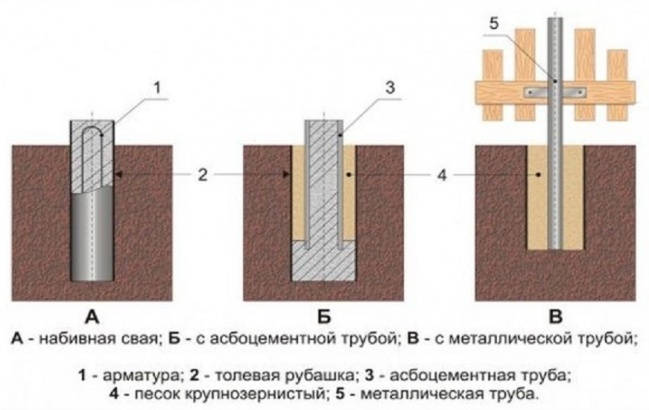

Ways to strengthen asbestos, metal or plastic pipes in the soil have some differences

Benefits of the foundation of pipes

Tubular foundation is a type of pile design, when the construction of which does not use concrete blocks, pillars or beams, and not wooden supports, but different kinds Pipes - metal, plastic or asbestos. Beginner builders prefer the point option due to the ease of incarnation of the project into life, and more experienced the modest estimate and the rapid achievement of the result.

One of the installation options in the soil pipe with a diameter of 200 mm

Non-professionals who have already had to face a pipe foundation, allocate the following advantages:

- land work is minimized - in a large pit or an ideally lined platform, there is no need;

- the bookmark takes a short period of time, after which you can start building a house (for excerpt enough week, while ribbon foundation "Purses" 3-4 weeks);

- communication laying does not cause difficulties;

- the construction is protected from possible floodings, as the account of the supports is raised above the ground.

Height above the level of soil depends on the type and size of the structure

If we roughly calculate the amount of material and the cost of construction work (service team services), we will see that the ribbon design will be twice as expensive. Metal or plastic pipes for pile foundation, land bur, concrete mixer - here is perhaps the most cost items of the project. A hand tool required to build formwork is in every home.

Foundation Device Scheme on Screw Piles

Construction of tubular foundation with their own hands

Before starting earthworks, you should reflect the plan-scheme of the future structure on paper, make detailed calculations, explore the site and make markup. The main factors relating to the foundation are the supports themselves (their number, view, intervals between them), the depth of the holes, the characteristics of the soil, the load on the soil, the presence or absence of groundwater, the height of the structure above the ground level.

Approximate scheme for creating a swallowed tubular foundation

Plastic pipe design

When choosing plastic pipes for a columnar foundation, focus on the stronger products intended for external sewage. They are easy to learn on brick-orange color, while the products for internal works are gray. Manufacturers provide a guarantee of 45-50 years, but if reinforcing the formwork by reinforcement or framework, the supports will serve for 20 years longer.

Pipes for external sewerage differ in color and technical characteristics

PVC pipes for external sewerage have a complex of characteristics, valuable for earthworks and construction construction for a large load:

- easily carry low temperatures, which allows them to be used in medium latitudes and in the north;

- resistant to external aggressive impact (chemical and mechanical);

- despite the strength of the material, have low weight;

- thanks to the smooth surface, it is better tolerant movement of the soil.

Depending on the area and height of the structure, we determine the optimal parameters of the pipes: the length (from 1000 mm to 6000 mm) and the diameter (from 110 mm to 630 mm).

Order of work:

- Make a draft foundation from pVC pipe, taking into account the nuances of construction with their own hands, not forgetting about the number of supports, intervals between them, depth.

- Preparing the main material - plastic blanks for formwork. In order for the supports to purchase additional strength and stability, in the bottom it is necessary to make a broadening, the so-called "heel" - take a black tight package for garbage and fix it with a tape.

- In advance, weld the frame of the reinforcement for each support, prepare the studs for fastening the lower strapping from the bar (the stud will "look out" from concrete fill).

- We drill holes exactly on the markup so that the lower part of the supports is below the level of freezing.

- Insert the billets from PVC into the wells, concrete broadening. Observe general level Heights, for this we use a tensioned construction cord. The second option is possible - trimming the blanks at one level after installation.

- We increase the formwork in advance prepared frames from fittings.

- The final stage - each pillar fill with concrete. In the upper part, fasten the hairpin.

To increase the service life and protect the supports from destruction, top, towering over the soil, process with bitumen mastics or close the rubberoid.

Metal supports

The main advantage of the foundation from metal pipes is its durability. Unlike plastic and asbestos analogs, steel piles will preserve not one hundred years, but with the only condition - if you have the right anti-corrosion processing of supports along the entire length. Another disadvantage is the high product price, but it justifies itself if you build not a tool cutting, but a country house for temporary or permanent residence.

Building a skeleton house on a tube foundation

The metal is not so easy to handle as asbestos or polyvinyl chloride, so when clogging piles, you must monitor the level. With inaccurate observance of the given height, it is necessary to maintain steel supports, and it will take a lot of time and strength.

Installation of metal supports is made in two ways:

- The simultaneous fill with concrete of pipes and shurph (a plot located inside the perimeter of the foundation). To comply with the horizontal and increasing strength, a metal frame is used connecting all the supports - Ruralsk. For welding, the frame is suitable for steel galvanized profile.

- The use of double pipes - first ride the base of the larger diameter, carrying supports are inserted into it, then poured with concrete. This method protects against metal deformation, which is possible in the hot season.

If the basis for the construction of a residential building is prepared and the arrangement of communications will be required, it is necessary to remember that the sealing of the glands during the passage of pipes through the foundations, the cellar cellar is regulated by the standards of state estimated norms.

Combined asbotic foundation

Asbo-cement, along with metal supports, used for a table foundation from pipes. It has been proven that the combined structures are much stronger point supports, therefore, a concrete tape is used as additional protection. The formwork is built according to the usual scheme of sheet iron, wooden boards or plywood sheets.

Asbicated or metal pipes are combined with angle or profile

The main thing when pouring concrete is waterproofing the inside and the absence of cracks and cracks. From the ribbon foundation it is necessary to refuse if the construction is carried out on movable soils, since the additional concrete fill may cause the destruction of the entire design as a whole.

Thematic video

Video: Foundation on screw piles

With simplicity and ease of construction of the structure of tubular type, not always used. For example, they are relevant when it is planned to build a small area of \u200b\u200ba wooden building, and for a stone cottage with an increased carrier load is preferable to a ribbon foundation.

Videos: Sail-screw foundations

Due to the raised open design and the absence of a pit, the difficulty in the construction of a cellar or basement arises. On the territory with variable heights or with movable soil, you should also choose another type of design.

The basis of any structure is the foundation, the design on which the building relies, transmits its weight to the underlying soil and therefore is one of its most important elements. The most popular appearance, on the simplicity of its device and economy - columnar.

Depending on the materials used, the columnar foundations may be the following: brick; Concrete - monolithic or ready-made blocks; wooden; from a metal profile; From pipes: asbestos-cement, plastic, metal. Of the variety of columnar structures, it is possible to highlight the foundation from steel pipeswhich is often used when building one-storey buildings and little responsible buildings - garages, storerooms, sheds, large arbors, grill houses.

It is a field of pillars located in the corners of the structure, places intersection of outer walls and carrying partitions. The recommended pitch is 1.5-3.0 m, depending on the mass of the construction. Such structures are successfully used in areas with a slope and during construction on weak soils and can be built with their own hands.

The main advantages of the foundation of pipes - a high bearing capacity, the absence of deformations while compliance with the device technology, is not required to perform large volumes of earthworks, a short period of construction and low cost, since it does not require the use of complex construction equipment for digging and planning the territory and its territory You can make it yourself. In addition, a small amount of reinforcement and concrete will be required for such a foundation.

Subject to technology, the foundation quickly gains the necessary strength and has a long service life. The advantages of the foundation from pipes include the possibility of its device on flooded and moistened territories. In addition, the supply of communications to such buildings is simple enough.

The disadvantages of such foundation include:

- relatively low bearing capacity and as a result of limited use;

- the need to insulate the floor during the operation of the building in the cold season;

- the impossibility of the basement device; The impossibility of use in areas with a large bias.

A variant of the pile device is possible from 2-3-pipes smaller diameter, which are set at a distance of about 5 cm from each other.

Consider the sequence of the foundation device from the pipes with your own hands.

Preparatory work

For the proper foundation device, it is necessary to take into account the following parameters: the depth of the primer of the soil at the construction site, the presence and depth of groundwater occurrence, the characteristics of the soil, the total weight of the building.

Pipes with a diameter of 250 mm

Pipes with a diameter of 250 mm Then you should prepare tools and materials:

- motor or manual drill;

- concrete mixer;

- welding machine;

- bulgarian, screwdriver;

- a hammer;

- nails;

- level;

- cement, brand not less than 400;

- sand;

- crushed stone or gravel;

- armature with a diameter of 10 or 12 mm;

- boards for the device of a wooden painter or formwork for concrete woodwork;

- pipes d \u003d 250-300 mm;

- bitumen or bitumen mastic.

The markup of the site is performed, pegs are driven into the places of future wells, the recommended step is 1.5-3 meters. Prepare pipes: the length of the pipes must be half the meter more depth of the well, carefully deceive the surface of the pipe and the lower end to the bitumen mastic or preheated bitumen, which is recommended Add 10% of working out, to give greater elasticity.

Foundation device with your own hands

Using a manual or gasoline drum, the wells are placed to install pipes. The depth of the well, approximately half a meter below the depth of the primer of the soil in a particular area (for the Moscow region takes 1.8 m). Sand or gravel pour into the well to create a drainage layer 150-200 mm. Then the prepared pipes are immersed, with the help of the level and long board, the horizontal of the pile field is checked, if necessary, cut the pipes with a grinder.

Using a manual or gasoline drum, the wells are placed to install pipes. The depth of the well, approximately half a meter below the depth of the primer of the soil in a particular area (for the Moscow region takes 1.8 m). Sand or gravel pour into the well to create a drainage layer 150-200 mm. Then the prepared pipes are immersed, with the help of the level and long board, the horizontal of the pile field is checked, if necessary, cut the pipes with a grinder.

The inner volume of pipes and in the presence of a gap between the walls of the pipe and the well, this space is filled with concrete with layer-by-layer plug. When building a building with a height of more than one floor, 3-4 reinforcement rods must be placed in the pipe.

5-7 days after filling the pipes with concrete and the initial set of strength, proceed to the next step of the building of the building of the building with their own hands - the installation of woodwork. Scarlet can be made of wooden bars, metal (schwelller or profile pipe) or concrete. Concrete is the most time consuming, but more accessible to the device with their own hands. For its manufacture, it is necessary to install a wooden formwork for 200-300 mm above the level of the ground, 0.5 m wide, 0.3-0.5 m high. Look at the video, how to pour the foundation from the pipes with your own hands.

The reinforcement is stacked, it is advisable to privar on the pipes. The formwork from the inside is lined with a cellophane film to eliminate the leaks of cement milk. The formwork is layered, filled with concrete with pin. After 5-7 days, the formwork can be removed. The foundation is ready for the construction of a house or any economic building.

The foundation from steel pipes is the most common design and accessible to the device with your own hands, has a high bearing capacity and low cost. Also, his advantage is that it is suitable for use on flooded areas.