- The surface of the wall is cleaned of dust, then slightly moistened.

- The solution is taken on a trowel (spatula), then poured onto the prepared surface. As a result, the layer is uneven, and this is exactly what is necessary for better adhesion between layers.

- The second layer is thicker. It is applied with a trowel over the entire surface of the canal, from the very beginning to the end.

Sheathing with asbestos-cement sheets

This method allows you to save twice as much heat. Its essence is in finishing the brick walls of the channel with asbestos-cement slabs. Gluing is performed on a plastering solution, which is prepared according to the above technology.

- After the surface is reinforced with a metal mesh, the first layer of plaster is applied by spraying.

- The second layer is applied to the dried first layer and asbestos-cement sheets cut to the appropriate sizes are glued to it.

On a note

Given the lack of environmental friendliness of asbestos, this method of thermal insulation of the chimney is more suitable for cold attics. It allows you to partially balance the thermal regime inside and outside the pipe, which significantly reduces the formation of condensation, as well as improves fire protection.

Sheet metal can be used for finishing brick structures. Such cladding is performed on a layer of insulation.

Creating an insulating casing

A single pipe made of metal, not protected by insulation, is the most dangerous option from the point of view of fire. In addition, it does not store heat well, given the high thermal conductivity of the metal. Between it and structures made of wood and plastic, you need to maintain a distance of at least 60 cm. But even then, you can get burned if you accidentally touch it. Therefore, the issue of isolation still remains relevant.

The simplest insulation method in such a case is to create a multi-layer sandwich structure.

- The overlapping chimney is wrapped with mats made of non-combustible basalt wool, which are thinner than 50 mm. The melting point of this insulation is close to 1000˚, which is much higher than the smoke temperature.

- A knitting steel wire is laid over the thermal insulation and secured.

- Then plaster is applied according to the above-described technology, using a cement-lime or clay-sand mortar.

- A sheet iron casing can be used instead of plaster. The sheet must have a width of at least 1 m. The metal blank is rolled up along the pipe diameter with a layer of insulation and riveted along the edge joining line. The corners are rounded by hand or using rolling rollers.

On a note

The isolation process is continued, repeating the procedure the required number of times. In this case, the next sheet is laid with an overlap, securing its lower edge.

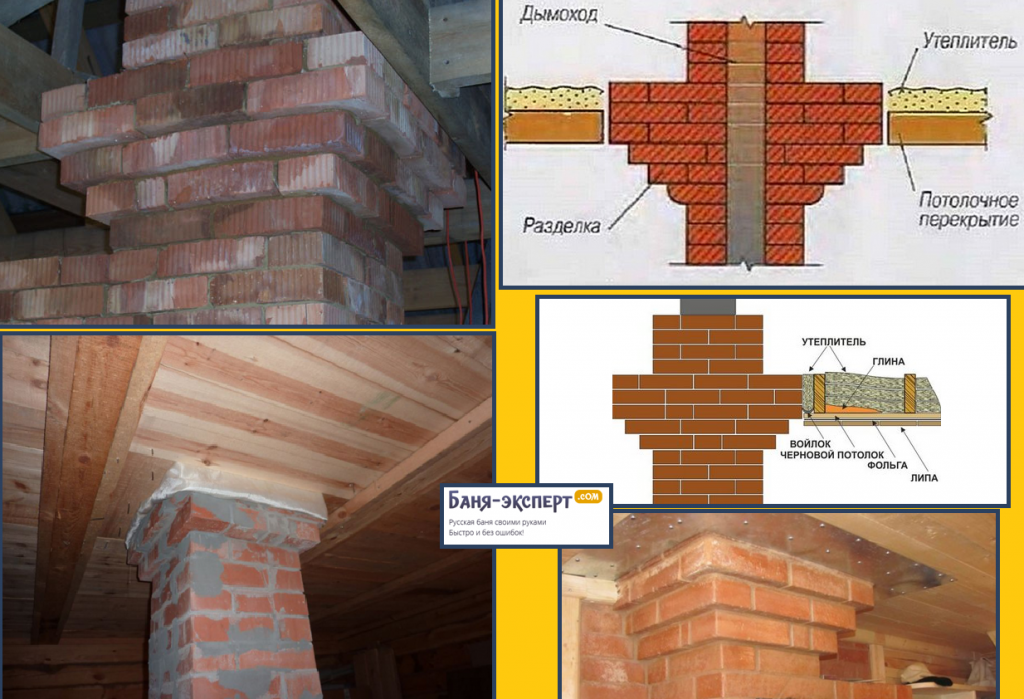

Chimney insulation in the ceiling

![]()

The sections of the smoke channels in the place where they pass through the ceiling are perhaps the most critical, and therefore require special attention. This event is mandatory when installing any type of chimney. It assumes a box device.

When performing the passes, the following conditions are met:

- The edges of the holes made on the roof and in the ceiling should be at least 0.25–0.35 m farther than the edges of the chimneys.

- This space is tightly filled with non-combustible heat-insulating material. As a rule, it is stone or basalt wool.

- Wood structures located near the aisles are treated with fire retardants.

Even when insulated, the chimney also needs proper operation. In particular, it must be cleaned of soot at least three times a year, timely emptying the furnace of ash from the furnace, and using materials for the furnace that are intended exclusively for these purposes.

The construction of a chimney in a private house presupposes compliance with the rules of sealing and fire safety. When constructing a chimney in a house or at the outlet of a metal chimney in a bath through the roof, the chimney insulation is the main indicator of the correct organization of this block of work.

The joint of the chimney with the ceiling and roofing materials remains a vulnerable area due to possible overheating and fire of the roof. To exclude the possibility of a fire, it is important to organize the insulation and sealing of the roof according to all the rules.

Pipe insulation at the joint

The release of new building materials and the development of advanced technologies are a guarantee of effective thermal insulation. The choice of materials for this purpose is largely determined by the shape of the chimney, the way of wrapping the pipe that removes hot gaseous substances during fuel combustion.

The main difficulty is not to allow the materials adjacent to the chimney to heat up unnecessarily, so that they do not ignite in any type of building.

Most of the buildings in private households have a chimney coming from:

- solid fuel boiler;

- fireplace;

- ovens;

- cooking plates.

They have a different degree of load and the level of heating to the maximum temperature, but insulation is needed in each case. A prefabricated or modular chimney, produced as a sandwich system, presupposes ready-made insulation of double pipes with a layer of basalt wool. It is effective both for insulation, to reduce the likelihood of condensation, and as protection against overheating of roofing materials exiting through the roof. It remains to properly organize the tightness of this passage so that moisture does not enter the house.

Ceramic chimney kit

Ceramic chimney kit Before insulating a pipe in a bathhouse or a residential building, you should choose the option most suitable for your design. The ceramic chimney is no less effective and durable; it is used for a fireplace or a bath. The assembly of the finished structure includes components made of fire-fighting materials. Some of them adjoin directly to the pipe or cover it, others are designed to seal the passage through the roof.

The choice of the place for the outlet of the chimney should be such as to facilitate the insulation work. But the pipe should rise 30-40cm above the ridge, in order to avoid reverse thrust in strong winds, so the pipe is often led out through the ridge.

How to choose the right place for the chimney outlet

Example of an external chimney outlet

Example of an external chimney outlet In houses of the old construction, when all the chimneys of the stove were made of brickwork, round pipes are led out through the square opening of the ceiling. The passage section in the ceiling is equipped with a special box made of wood or metal, observing a sufficient distance to the chimney.

It is important to properly insulate this "window" so that all gaps are filled and the materials at the joint are protected from fire. This gap is filled with mineral wool, and a special fire-resistant plaster is also used. Basalt and asbestos blocks are also used in a brick chimney.

Safe and secure outlet of the chimney pipe through the roof opening is solved in 2 directions:

- fire protection of the roof truss frame at the pipe passage;

- waterproofing the hole from the penetration of atmospheric precipitation with those materials that will help insulate the pipe and are most suitable for the type of roofing material and its color.

Conclusion of the pipe through the roofing pie in accordance with all fire safety standards

The separation of the chimney and the multilayer roofing cake (with insulation, hydro and vapor insulation) is carried out according to all modern standards:

- for double metal pipes, internal insulation with mineral wool is provided;

- a single pipe is covered with a finished insulating shell of the required diameter and protected from the outside;

- in brickwork, it is important to increase the wall thickness of the order (38-40 cm) and protect the contact surfaces with special plaster.

The box for the outlet of the chimney is constructed from a cross beam and rafters, keeping the distance from the wooden structure to the metal chimney at least 15 cm. The gap between them is filled with basalt wool.

The fire safety regulations state that the temperature in the contact circle of the chimney should not be higher than 50 ° C. The film membranes inside the roofing cake can be made of flammable materials, therefore, a gap and additional insulation with non-combustible mineral wool is required between them and the pipe.

The membranes of the roofing cake cut at the exit of the pipe must be carefully cut and rolled up. Then they are pressed with a crate and fixed along the edges of the box with nails. For complete tightness of the roof, the pipe in this place must be wrapped with a special sealing tape.

When the chimney runs through an unheated attic, and not in a residential attic, the risk of overheating of the roofing elements is reduced. Complete tightness of the insulation is necessary in any case, but it is better to additionally wrap the pipe with a special tape. Competent installation of the inner waterproofing and the outer cap will ensure reliable sealing after the thermal insulation of the chimney is installed in the opening of the roof covering.

Exiting the pipe through the roof

Exiting the pipe through the roof Chimney insulation options

In most cases, well-designed chimney insulation on the roof counteracts precipitation leakage. But there are 2 types of possible leaks:

- from above, when the insulating hood is not correctly installed over the roofing materials;

- from below when waterproofing agents have not been correctly positioned under the deck.

The simplest way to externally insulate a chimney is to install a ready-made insulating apron or hood.

Try to cut such a device from the galvanized sheet yourself to eliminate the leak in the old roof, this will save money. With this method, no adjustment is needed - all the structural features of the roof and the pipes coming out of it are taken into account.

Products of this type are also available in different materials. It is important to choose an insulating hood (apron) that fits the width of the metal chimney. Or a complete roofing passage is selected, which is purchased together with a sandwich pipe.

Pipe thermal insulation option

Pipe thermal insulation option Any building and roof gradually shrink, therefore, rigid fastening of waterproofing is not always effective. Visually, the integrity of the roof is preserved, and signs of depressurization gradually appear at the joints. Experts recommend to strengthen the insulation in the places where the hood is attached - with an elastic heat-resistant gasket.

Among the most reliable structures for the passage of a pipe through the roof, a specially made box is considered - according to the type of rafter system. Instead of wood, which is a flammable material, it can be made of galvanized roofing, but according to the same scheme.

The design of modular chimneys has ready-made thermal insulation, but they differ in configuration. For example, there is a double pipe with a layer of basalt wool or a special ceramic core and an outer shell made of concrete. The assembly of modular blocks is quite simple - the diagram is attached with the purchase.

It is possible to install an asbestos gasket, followed by sealing with an asbestos mortar. Each new block of the module is attached over the previous one with the same composition of the mixture. After completion of the installation, the pipe is isolated from a leak in the roof window in any way described.

Modern roofing with corrugated board has its own characteristics - here it is better to make the window for the chimney a little wider. All abutting surfaces are also filled with materials with thermal insulating properties. The chimney, before being wrapped with basalt wool, is placed in a steel box. Carefully cut the film layers of vapor and waterproofing, fix by the edges of the box. It is imperative to make a heat-resistant filling between it and the pipe.

Roof penetration

Roof penetration Next, external waterproofing is carried out - a sealing cap material corresponding to the dimensions of the chimney pipe is put on from above, the edge is fastened with a clamp to glue. The lower edge is tightly fitted to the roofing material, rigidly fixed with a sealant. A steel cap is often included with such a chimney. They are put on rounded pipes. Installation is recommended when the outlet smoke from the solid fuel boiler has a temperature of more than 100 ° C.

If you properly insulate the chimney pipe, then you will not be in danger of dampness and rotten ceiling.

The article will discuss how and with what to insulate the chimney pipe. Several practical ways are presented.

Insulation of the chimney pipe is required to avoid leaks and overheating. Simply put, it allows you to increase the life of the structure. Experts recommend performing complex work, which includes hydro and fire insulation.

Bath chimney

When performing the insulation of the chimney in the bath, the safety of people should be paramount. The main threat in the room comes from open flames. Therefore, it must be protected, having previously made the overlap resistant to high temperatures.

Basically, baths are built from wood, a flammable material. A very common misconception is the opinion that sheathing the ceiling with metal sheets will be a sufficient measure. But in reality, such protection is not enough. After all, the upholstery will still heat up, which can lead to ignition. A popular solution to the problem is to insulate the chimney with red bricks. But this is not suitable for every bath design.

There are now two good options for chimney insulation:

- Folgoizol... A bath with such insulation will not lose heat, everything works like a thermos. At the same time, it warms up quite quickly, maintaining the temperature for a long time.

- Teploizol... The material is used for winding the chimney.

A popular solution is to use sandwich pipes that demonstrate high degree security. The insulation structure consists of several sections that can be easily combined with each other. This option is also suitable for saunas with a metal stove.

It is important to take a responsible approach to the brickwork in the bath. The duration of the structure's operation directly depends on its quality. You cannot save on materials or work. After all, the need for repairs in the future will be associated with much higher costs.

Metal chimney winding

"How to wrap a metal chimney pipe in a bath?" - a popular question among summer residents. After all, there are many materials used for this summer cottage. The absence of flammable substances in the coating is the primary nuance that must be taken into account. It is preferable to use quality material with all the necessary properties. Also, it must be completely safe to use.

The most common materials:

- Glass wool;

- Fibrous building materials;

- Mineral wool.

Insulation of a metal chimney

Thermal insulation of chimneys of a metal chimney is a separate topic for discussion. After all, it contains a number of nuances, which will be discussed later. This is a very difficult task, therefore it is recommended to perform it during the construction of the bath. It is more difficult to work with a finished building, because the roof may need to be rebuilt.

A good solution would be to use sandwich pipes. This design is easy to manufacture, and the costs of specialists will also be reduced. However, the material itself does not belong to the budget. But the service life and quality fully justify its cost. Sandwich pipes are additionally insulated with mineral wool.

How to insulate the chimney, everyone decides for himself. It is important to remember that such insulation allows you to protect the chimney from the negative effects of combustion products, as well as moisture. If you do not worry about isolation in time, then there is a risk of destruction of the bath. After all, condensate, enhanced by the action of acid, slowly destroys building materials. It poses the greatest threat in the spring, when the pipe begins to thaw (in more detail: "").

Manufacturing of boxes

About how to insulate the iron chimney pipe, it was said earlier. Now you can move on to the next step. It seems to many that making a chimney box is too difficult a task. In reality, this is not the case. It is enough to approach work responsibly, competently.

Required tools:

- Drill;

- Metal scissors;

- Compass;

- Metal sheets;

- Self-tapping screws.

Stages of work:

- Hole preparation. Along the edges, it is necessary to fix the bars, which will act as a support for the body.

- Two blanks are cut from a metal sheet. They are given a U-shape. Then the finished parts are screwed to the ceiling with self-tapping screws.

- Again, two blanks are made, but they are already fixed on the standing sheets with a small overhang. It turns out a one-piece frame in the ceiling.

- Now the bottom for the box is made of metal sheet. In the center of the workpiece there should be a hole for the chimney, here you need a compass.

- The box contains four fasteners of two centimeters. They are cut and folded perpendicular to the bottom.

- Walls are attached to the bottom. Now a chimney is inserted into the box, it is additionally secured with clamps. The voids are filled with an insulating layer.

Chimney installation

Installing a chimney is not as easy a task as it might seem at first glance. There are many nuances to consider. If the chimney is not installed well enough, this can lead to damage to property, as well as creating discomfort for people inside, and causing harm to their health.

Stages of work:

- The preparatory stage, where a project of work is selected, materials are purchased, the form of construction is determined. There are straight chimneys, as well as designs with various bends.

- Now you can start assembling the chimney. The joints of pipes, elbows and tees must be fastened with clamps.

- Carrying out the chimney through the roof using a special tool. To begin with, the level of the roof slope is determined, based on the data obtained, a suitable place is selected. A hole for the workpiece is cut in it. From above, everything is insulated with a roof cut, and from the inside - with a cover sheet. Read also: "".

- A special apron is attached to the branch pipe. The pipe is lengthened to the required size, its top is partially insulated with a special umbrella-shaped cover. It will prevent atmospheric precipitation from entering the chimney.

Chimney fixing

The workpiece must be taken to the roof through the attic. All gaps, especially the voids between the roof and the branch pipe, are filled with waterproofing. When withdrawing the workpiece, you must remember the safety precautions.

A knee is used to secure the chimney pipe. It is designed to adjust the vertical position of the structure. To give everything reliability, the pipe is additionally attached to the wall, using suitable brackets. Usually they are included in a ready-made set. They can also be made by hand, it is best to use metal corners as a basis for them.

As soon as the insulating structure is in place and securely fixed, it is necessary to close the chimney pipe with an umbrella. It is designed to protect the structure from precipitation, poplar fluff and fallen leaves.

Replacing a brick pipe with a metal one

If the brick chimney is not enough, it can be further extended with a metal pipe. The task is laborious, but quite realizable. It is important to approach it responsibly.

To begin with, a flat steel platform with a branch pipe is made. Moreover, its diameter should be the same as the diameter of the metal pipe that is planned to be used. The platform must be securely fixed. It is fixed with dowels and screws. Sealing will add additional reliability.

Work order:

- On the brickwork, you need to mark the points at which the mount will be installed. They must not be placed on a masonry seam. It is advisable to place them closer to the center of the brick, and not on its edge.

- Holes are drilled in the marked places to accommodate the dowels. At the same points, holes are made on a flat platform, self-tapping screws will go there.

- A refractory sealant is applied to the brick base, then a steel platform is placed there. Self-tapping screws are screwed into the dowels. It is important to monitor the tightness and uniformity.

- Now it remains to wait for the sealant to dry completely and go directly to lengthening the chimney using a metal pipe.

Important nuances of installation:

- If the length of the pipe section above the roof exceeds 1.5 m, it is recommended to equip it with special braces that strengthen the structure (read also: "").

- Do not install a branch pipe, the length of which from the stove to the head is more than 5 m.

- Installing special plugs allows you to get rid of condensation.

- The chimney section above the roof must be longer than 1.5 m.

- Do not narrow the pipe when installing the chimney.

- Nearby structures made of flammable materials should not be heated to a temperature of 50 o C.

- The chimney must not be placed near electrical wiring.

The decision on how to insulate the metal chimney pipe should be made based on the budget, as well as the needs of the structure. It is important to approach the task as responsibly as possible, performing work in full compliance with all norms and nuances. Then the chimney insulation will last a long time without any complaints.

Question: "How to insulate a metal chimney pipe?" asked very often. This has to be done from such destructive factors:

- overheating of the structure;

- leakage at the butt joints.

Solving the problem of how to insulate a metal chimney pipe in a bathhouse, the safety of people must be prioritized.

The main threat in this room is the presence of live fire. It is imperative to isolate in this case. Without protection, the overlap can easily light up.

Most often, the bath is built of wood, and as you know, this material is easily flammable. Many people mistakenly believe that upholstering the ceiling with metal sheets will be an excellent protection, and that it is no longer necessary to insulate.

But, this protection heats up and it will not save from ignition. You can insulate the pipe with red brick, but not every bath design is suitable for this.

The market for modern building materials to insulate the chimney provides several products:

- Folgoizol. Sauna with this finish is similar to the design of a thermos. Heat is not lost, the room heats up quickly and cools for a long time.

- Thermal insulation. They can wrap a chimney pipe and secure with wire or special metallized tape.

There is no need to worry about isolation with them. This structure is constructed of several sections that can be easily inserted into one another. It is suitable even for a sauna with a metal stove.

For construction in a traditional Russian bath, red brick is used. It is not exposed to high temperatures and keeps warm for a long time.

Such a building must fit correctly. Because the duration of the use of the structure depends on the indicator of the quality of the masonry.

How to wrap a metal chimney

How to wrap a metal chimney pipe is not difficult to decide. The building materials market offers many products for this.

IMPORTANT! The most important thing that you need to know when performing insulation is that you cannot take a coating for it that contains flammable substances.

Better to insulate with a good quality product that complies with fire and building codes. This will create additional security conditions.

Of the options offered, the most commonly used are:

- Fibrous building material;

- Mineral wool;

- Glass wool.

We will learn how to insulate a metal chimney

The metal version, and in particular its insulation, deserves special attention. drawing up a construction project.

It is not always possible to isolate an already created scheme without rebuilding the roofing structure.

If you build a modern structure, you can use ready-made "sandwich" pipes. Such designs are carried out quickly, with little expense for specialists.

But, they are not cheap. However, this cost is justified by the long service life and ease of construction.

In them, mineral wool is located between two blanks. The insulation thus comes out at the highest level.

With the help of insulation, they stop or prevent irreversible chemical reactions that take place under the influence of moisture and fuel decomposition substances.

Measures not taken in time to insulate the chimney pipe can become the basis for violating the integrity of the house due to destruction.

The condensate, strengthened by the action of acid, slowly, but intensively spoils the building materials. Condensation is especially dangerous during the thawing period of the pipe after winter.

Manufacturing of boxes

Many people are afraid to make a metal box for the chimney pipe on their own. But, this does not contain much difficulty.

When making a box, you need the following tools:

- Scissors for metal.

- Galvanized sheet.

- Self-tapping screws.

- Tsyrkul.

- Drill.

Further sequence of actions:

- The hole is being prepared. Its edges must be secured with support beams. They will create support for the box.

- A couple of parts are cut from the galvanized sheet. Along their edges, at a distance of five centimeters, a 90 degree fold is made. These u-shaped parts are fastened with self-tapping screws to the prepared holes in the ceiling covering.

- Similarly, two more U-shaped blanks are prepared, and they are overlapped onto the already standing sheets. As a result, a solid framing of the done exit comes out in the ceiling covering.

- The next part of the action is the bottom for the box. From the same galvanized sheet, an element is cut out, corresponding in size to the opening made. In its center, a circle is drawn with a compass for the entrance of the flue gas blank.

- 4 fasteners are placed from the central part of the box bottom (each of them has a two-centimeter width). Then they are cut and folded at an angle of 90 degrees. As a result, a base is formed with a hole and 4 strips for fasteners.

- The bottom is attached to the walls. A chimney is inserted through the outlet and fastened with a clamp. The empty space is filled with an insulating layer.

According to the proposed instructions, it is not difficult to make a box. If you follow everything exactly, the work will not be difficult even for an inexperienced layman.

Chimney installation

The problem of how to properly install a chimney from metal pipes is not solved as easily as it seems at first glance. It is very important that it functions as it should.

Otherwise, combustion products will not only damage furniture items, but also harm the human body.

Any building of this type is done according to the following principles:

- About the smoke. At the same time, a tee is installed in the network, which removes condensate.

- Relative to condensation. However, this tee is not used.

First stage... This is the choice of the project and the selection of materials. At this stage, it becomes clear what kind of building will be (straight or with transitions and folds).

Second phase... This is an assembly. All joints, elbows and tees must be securely fastened with clamps.

Stage three... Passage through the roof. Through the roof, the withdrawal takes place using a special cut.

It is chosen according to the level of the roof slope. Then the place where the workpiece will pass is determined.

The angle of the slope is regulated by a part of the groove, and its extreme parts are "adjusted" to the ridge. Insulation is laid along the walls of the branch pipe.

Fourth final stage... An adjustable apron is attached to the branch pipe and the pipe is extended to the required length. Its edges are closed with a cover - an umbrella. It will protect against precipitation.

Chimney fixing

In this case, the gaps between the roof and the branch pipe must be closed with waterproofing. Raising the structure above the roof is recommended in accordance with existing rules.

When carried out from the outside of the structure, the problem of how to fix the metal chimney pipe is not acute. Because for this they use the knee, which sets the direction of the vertical position.

For reliability, the chimney is fixed to the wall with special brackets. They can already be contained in a ready-made kit upon purchase, and it is also not difficult to make them yourself from a metal corner.

When the structure rises to the level of the roof ridge and is securely fixed to the wall, an umbrella must be worn on top of it. It protects against clogging by fallen leaves, rainwater and snowfall.

Transition from a brick chimney to a metal one

How to lengthen a brick chimney metal pipe? This question is asked very often.

To lengthen a brick chimney, a flat steel platform with a pipe should be made. The diameter of the nozzle must match the diameter of the workpiece to be extended.

This extension pad must be securely fixed. To do this, take dowels and screws. But, such an attachment will not be reliable without a sealant.

And now all the lengthening actions are in order:

- On a brick base, all attachment points must be marked. These places should not be on the masonry seam. Also, they should not be on the edge of the brick.

- Next, holes are drilled in the site for self-tapping screws, and holes for dowels are made in the bricks.

- The site is placed on.

- After that, the platform is evenly attracted along the entire perimeter with self-tapping screws.

- Further, this transition can be mounted only after the sealant has completely dried.

Now a brick building can be lengthened to any desired distance with a metal blank.

Some installation rules

- If the smoke outlet rises above the roof by more than 1.5 meters, then it is recommended to additionally fasten it with guy wires.

- The length of the branch pipe from the stove to the head should not exceed 5 meters.

- For cleaning from condensate, special plugs are mounted.

- The structure should be taken out of the roof at least 1.5 meters.

- When installing the smoke outlet, its diameter must not be narrowed.

- Structures made of combustible materials located nearby should not heat up to no more than 50 degrees.

- The smoke outlet must be routed at a safe distance from electrical wiring.

When deciding how to insulate a metal chimney pipe, everyone makes a decision based on their preferences and financial capabilities.

The main thing in this business is to do everything in accordance with the norms and requirements, and then the work will please with a high-quality result.

The stove is folded, and the chimney stands proudly above the roof of the house. Do you think the job is over? Not at all - it's time to think about how to insulate the chimney pipe and protect the house from fire, and the roof from leaks. It is good if you thought about this question even during the design of the furnace - in this case, the insulation of the chimney will be reliable and safe. It is more difficult to isolate an already built chimney, sometimes this work entails a change in the design of the floors and roof. However, the costs will be offset by a sense of safety and comfort.

Chimney insulation types

It is necessary to isolate the chimney from two negative destructive factors: from overheating of structures and from leaks at the joints. Therefore, in the article we will consider two types of chimney insulation:

- Fireproof thermal insulation;

- Waterproofing.

It is recommended to immediately carry out complex insulation, solving not only the main problems, but also improving the operating conditions of the furnace. For example, insulating a pipe running through an unheated attic reduces the risk of overheating of wooden roof elements and reduces the risk of condensation, which can lead to excessive soot deposits, corrosion or pipe breakdown. Waterproofing the pipe will help to avoid rotting of the truss system and ceilings, as well as the destruction of the pipe if it gets wet.

Methods for fire insulation of chimneys

The simplest and most reliable, but not always the cheapest way is to install a "sandwich" type chimney made of ceramic or metal. In such chimneys, the inner pipe, which performs the function of removing smoke, is made of heat resistant steel or ceramics and is thermally insulated with non-combustible insulation: mineral, stone or basalt wool. The outer layer of the sandwich chimney is made of steel or ready-made claydite-concrete blocks.

Prefabricated Ceramic Chimney - Safe Solution

Prefabricated chimneys are completed with elements for fastening, revision, maintenance, as well as for connecting several heating devices. Installation of such a chimney is not difficult, but it requires compliance with the instructions, only then it will be completely safe.

Thermal insulation of a "sandwich" pipe

Video - sandwich diaphragm for the passage of the pipe through the ceilings

Another insulation method used when building a stove is a brick chimney. Due to the low thermal conductivity of the brick, its walls do not heat up dangerously high temperatures, therefore, no additional measures for the insulation of such a chimney are required, except for the correct execution of the fire-prevention cutting of ceilings and roofs. To save and facilitate the construction, a brick chimney is sometimes finished with a metal or ceramic pipe. In this case, they are thermally insulated according to the technology described below.

Thermal insulation of metal and ceramic single pipes is possible using boxes made of non-combustible materials and mineral non-combustible thermal insulation - stone or basalt wool. It is possible to operate such chimneys without thermal insulation, but performing fire-prevention cutting according to all the rules is mandatory in any case.

Chimney waterproofing methods

Chimney waterproofing is installed in the place of its exit to the roof. The larger the pipe and the farther from the ridge it is located, the more difficult the operating conditions await it: with rain, more abundant flows of water, in winter - an increased snow load. With insufficient waterproofing, rain and melt water penetrates inside the house, leading to leaks, decay of wood and destruction of concrete and brick structures, including the chimney itself.

The method of waterproofing depends largely on the shape of the pipe and the type of roofing. For round pipes, metal or polymer cuts are used, for rectangular pipes - metal aprons and abutment strips. How to waterproof a pipe is described in detail in the article, and then we will talk about the technology of thermal insulation of the chimney.

Chimney pipe insulation

Before proceeding with the insulation of the chimney pipe, it is necessary to check compliance with the requirements of SNiP 2.04.05-91 and, if necessary, correct the shortcomings:

- The height of the pipe to ensure good draft and allowable temperature of flue gases at the outlet should be 5 meters or more;

- If the roof covering belongs to combustible materials - slate, ondulin, roofing material - a spark arrester must be placed on top of the pipe - a fine-mesh metal mesh;

- The distance between the chimney pipe and combustible structures - ceilings, walls, rafter systems - must be at least 250 mm;

- A fire-prevention distance must be maintained between the upper ceiling of the stove and the ceiling. For metal stoves, it is at least 1.5 meters, for brick stoves with a two-row overlap - 0.5 meters, with a three-row overlap - 0.25 meters, provided the ceiling above the stove is finished with non-combustible materials;

- In places where the brick chimney passes through the ceiling, fluff is performed - a thickening of the pipe. The thickness of the fluff is 1-1.5 bricks.

Plastering a brick pipe

The brick pipe does not heat up very much from the outside, therefore it is necessary to insulate it rather in order to improve operating conditions and extend its service life. The most affordable way to insulate a brick chimney is to plaster with cement mortar or a mortar based on cement and lime. Instead of sand, you can add sifted slag crumbs to it.

Solution composition:

- 1 bag of cement (25 kg);

- 2 buckets of slaked lime;

- 10 buckets of sand or a mixture of sand with slag crumbs;

- 5 buckets of water.

- To prepare the solution, mix 3.5-4 buckets of water with a bag of cement and 2 buckets of slaked lime - fluff. After thorough mixing, add sand and slag crumbs in parts, as well as the remaining norm of water. The resulting composition must be used in cool weather within 5 hours, and in hot weather - in 1-2 hours, so you can cook it in parts.

- With large irregularities in the pipe, the plaster layer turns out to be quite thick, therefore it is recommended to first seal all the cracks and drops with the specified solution, and then cover the pipe with a reinforcing mesh.

- Plastering is carried out in two layers. For the first layer, the solution is diluted a little more, to a creamy state, and applied by spraying: they take a certain amount of solution on a trowel or spatula and sprinkle it on a dust-free and slightly moistened brick surface. The first layer is not leveled.

- A thicker solution is needed for the second layer. It is applied with a trowel and rubbed to a smooth surface. It is necessary to plaster the entire pipe from floor to ceiling or roof.

Sheathing of brick pipes with asbestos-cement sheets

This method surpasses plastering in terms of heat saving by 2-2.5 times and consists in gluing asbestos-cement slabs to cement-lime mortar on the outer walls of the pipe.

- According to the above technology, a plastering solution is prepared.

- The pipe is reinforced with a mesh and the first layer of solution is sprayed on. Dry it.

- Asbestos-cement sheets are cut to fit the pipe size. The second layer of the solution is applied to the sheets of asbestos cement and glued to the surface of the chimney.

The disadvantages of this method include the low environmental friendliness of asbestos - it emits carcinogens, therefore it is impossible to use this method of isolation in living rooms. In a non-residential attic, thermal insulation of the chimney with asbestos will reduce the temperature drop from the inside and outside of the chimney and significantly reduce the formation of condensation, as well as improve its fire protection.

Besides, brick pipe can be sewn up with sheet metal using a layer of insulation. How to do this can be found in the video.

Video - pipe sheathing with sheet metal

Insulation of metal single pipes

The most dangerous version of the chimney in terms of fire safety is a metal pipe that is not protected by a heat insulator. The distance from such pipes to wooden and plastic structures should not be less than 0.6 meters. But even observing this distance will not protect you from burns if accidentally touched, so it is better to isolate the pipe without waiting for problems.

Uninsulated metal pipe is a common cause of fires

The easiest way to insulate a single pipe is to wrap it with a layer of non-combustible insulation, for example, basalt wool, and protect it from above with metal or plaster. The melting point of this material approaches 1000 degrees, which is significantly higher than the smoke temperature.

- Basalt wool mats with a thickness of at least 5 cm are wrapped around the pipe with an overlap and fastened by wrapping it over with steel wire.

- Wrap the heat-insulated pipe with a reinforcing mesh, fix it, and plaster it according to the technology described above in two layers with a cement-lime composition.

- Plaster can be replaced with thin sheet iron by rolling it along the diameter of the insulated pipe and riveting at the junction of the edges.

Insulation of floor and roof passages

The most critical sections of the chimney insulation are the passages through the ceilings, therefore they are given special attention. It is imperative to insulate passages when using any chimney: sandwich pipes, brick, and metal insulated.

Passages are carried out in compliance with the following conditions:

- In the ceilings and the roof, holes are made for the passage of the pipe so that there is a distance of at least 25-35 cm from its edges to the walls of the pipe.

- The edges of the hole are treated with asbestos-cement or metal sheets, and a box for thermal insulation is arranged.

- The space around the pipe is filled with stone or basalt wool without the formation of voids and gaps.

- Wooden structures located in the immediate vicinity of the chimney passages are treated with fire retardant compounds.

Insulation of passages through floors with basalt wool

Having figured out how to insulate a chimney pipe, you can easily do this work, but remember that even an insulated chimney must be properly operated: clean soot at least three times a year, remove ash from the furnace in a timely manner, do not burn in it not intended for firebox materials and items. All this is the key to a long and safe chimney service.