Seamless pipes made of stainless alloys are indispensable in industries and in conditions where it is necessary to transport or transfer media (gases or liquids) characterized by high temperatures, pressure and / or chemical aggressiveness. Due to the versatility of their characteristics, products made of 12X18H10T metal, manufactured in accordance with GOST 9941-81, are among the most demanded in various fields.

1 Seamless pipes 12X18H10T in accordance with GOST 9941-81 - how are they produced?

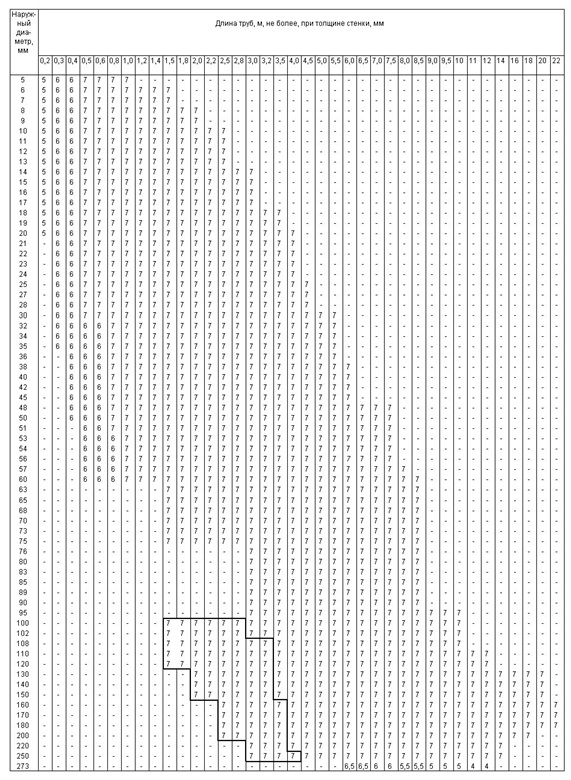

GOST 9941-81 applies to cold and heat-deformed seamless pipes made of corrosion-resistant steel alloys for general use, including the 12X18H10T grade. These pipes are produced with diameters (outer) of 5-273 mm and with walls 0.2-22 mm thick. The complete assortment, as well as the technical characteristics of the products, are indicated in the same standard - GOST 9941-81.

Depending on the size of the wall thickness and diameter, the standard maximum length of pipes produced is 4–7 m. For ease of use for various purposes, products are produced with the following lengths:

- Unmeasured length from 0.75 m to the maximum standard size - for pipes with wall thickness up to 0.5 mm.

- Unmeasured from 1 m to the maximum standard size - for products with walls 0.5–1 mm.

- Unmeasured in the range of 1.5–12.5 m - for pipes with walls from 1 mm and thicker.

- Dimensional - within the boundaries of unmeasured and at the same time not longer than the maximum standard value with a maximum deviation of +15 mm. By mutual agreement of the consumer with the manufacturer, it is allowed to manufacture rolled pipes with measured lengths greater than the maximum standard.

- Multiple dimensional - within the measured, if necessary, with an allowance of 5 mm for each cut and a maximum deviation of the total length of +15 mm. The smallest multiple of length is 300 mm.

- By agreement between the consumer and the manufacturer, it is allowed to manufacture rolled pipes with a length of over 12.5 m.

- By agreement between the consumer and the manufacturer, products with a diameter of less than 25 mm are allowed to be made in lengths up to 16 m.

In terms of manufacturing accuracy, pipes are produced with normal accuracy, with increased, with high.

For each type, depending on the size of the pipe, GOST 9941 regulates the corresponding maximum deviations (tolerances) of the wall thickness and diameter. The curvature of rolled pipes in any section with a length of 1 m should not exceed:

- 1 mm - for products of all diameters with walls 0.5 mm thick or more;

- 2 mm - for products in which the diameter exceeds 15 mm, and the wall has a thickness of less than 0.5 mm.

For rolled products with a diameter of less than 15 mm and a wall with a thickness of less than 0.5 mm, the curvature norms are not regulated. These products should not have sharp bends.

GOST establishes the following requirements for pipe ends. They are trimmed at a 90 ° angle (straight) and must be deburred. When removing the latter, the formation of roughness and chamfering is allowed. At the request of the customer, pipes with a wall thicker than 5 mm are supplied with ends that have a bevel for welding.

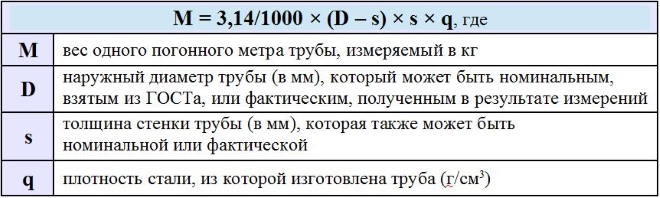

2 Weight of seamless pipes 12X18H10T, manufactured in accordance with GOST 9941-81

In GOST 9941-81 there is no data on the specific gravity (weight of 1 m length) of seamless products manufactured according to this standard. This is due to the significant amount of regulated steel production. For the manufacture of seamless products according to GOST 9941, 20 corrosion-resistant general-purpose alloys can be used.

To determine the specific gravity of a pipe of a specific standard size in GOST, it is proposed to use the following formula:

M = 3.14 / 1000 * (D - s) * s * q, where

M is the weight of 1 m of the product in kg;

D - nominal (from GOST) or actual (measured) outer diameter of the product, mm;

s - nominal or actual pipe wall thickness, mm;

q is the density of the alloy from which the product is made, g / cm 3.

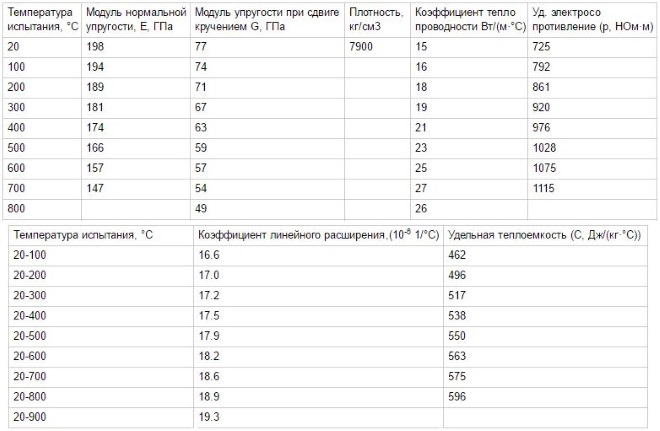

In GOST 9941, densities are given for all used steel grades. For alloy 12Kh18N10T, the value of this characteristic is 7.9 g / cm 3.

To calculate the mass of pipes made of this steel, with a diameter of, for example, 50 mm and with a wall thickness of, say, 4 mm, we first determine the specific gravity by the formula:

M = 3.14 / 1000 * (50 - 4) * 4 * 7.9 = 4.56 kg.

The total weight of all pipes is obtained by multiplying their total length by the calculated specific gravity. One product with a standard length of 7 m will weigh: 7 * 4.56 = 31.92 kg

3 Basic technical requirements, characteristics and features

The chemical composition of 12Kh18N10T steel used for the manufacture of pipes must comply with the one regulated by GOST 5632. The sulfur content in the alloy intended for the production of products to be welded (this is indicated in the customer's order) should not be higher than 0.02%. It is allowed to produce rolled pipes from steel with microadditions of rare-earth metals.

Pipes of GOST 9941 during manufacture must be heat treated. At the request of the consumer, products are produced thermally untreated and without surface clarification. In this case, the norms of curvature and mechanical properties of pipes are established by agreement between the customer and the manufacturer.

In terms of mechanical properties, products made of alloy 12X18H10T are one of the best. So, for them, the minimum value of the yield point, regulated by GOST 9941, is at least 22 kgf / mm 2 (216 MPa). The yield point is a parameter of a material that characterizes the amount of stress, upon the occurrence of which deformation in it will continue to propagate and grow without a subsequent increase in the load.

The ultimate tensile strength of these pipes is not less than 56 kgf / mm 2 (549 N / mm 2), and the relative elongation is not less than 35%. At the request of the customer, products are tensile tested at 350 ° C and they must withstand this test.

The inner and outer surface of pipe-rolling GOST 9941-81 should be free of sunsets, flaws, cracks and captivity. Elimination of defects is allowed to be performed by local cleaning, boring and turning, local or continuous grinding, provided that, as a result of the work performed, the wall thickness and / or diameter of the pipe will not be taken out of the limit minus deviations regulated by the standard.

The surface of rolled pipes must be necessarily light. Matte with a gray tint is acceptable, if this is due to the method of production of the product. It is allowed to produce pipes without etching after heat treatment in a vacuum or protective atmosphere with tarnishing colors on the surface.

At the request of the customer, pipes made of alloy 12X18H10T must withstand the flattening or expansion test in accordance with the standards established for this by GOST 9941. In addition, at the request of the consumer, the products are checked for their ability to withstand hydraulic pressure.

At the request of the consumer, which must be indicated in the order, products from alloy 12X18H10T are made resistant to intergranular corrosion... Pipes produced without heat treatment are not subjected to expansion or flattening tests and intergranular corrosion susceptibility tests.

4 Comparison with seamless pipes 12X18H10T, produced in accordance with GOST 9940-81

Seamless products are also produced from steel 12X18H10T in accordance with GOST 9940-81. It applies to hot-deformed tubular products made from corrosion-resistant alloys for general purposes.

Unlike those discussed above, GOST 9940 is made with diameters (outer) 57–325 mm and with a wall thickness of 3.5–32 mm. The standard maximum length of these seamless products is 3–8.5 m. In terms of manufacturing accuracy, pipes are produced with normal and high accuracy. Other geometrical dimensions and physical and mechanical properties, which are described below, determined for pipes 12X18H10T GOST 9940 and other tolerances for wall thickness, diameter and curvature.

The same requirements are imposed on the chemical composition of the steel of seamless products of this standard as for those produced in accordance with GOST 9941. And their mass is calculated using the same formula. The requirements for pipe ends and surfaces are also identical. Products are manufactured in accordance with the submitted order, heat treated or without heat treatment and resistant to intergranular corrosion. At the request of the customer, pipes are subjected to the same tests as those produced in accordance with GOST 9941, and using similar methods and conditions for their implementation.

Here the only difference is that their heat treatment is not a prerequisite for achieving the required physical and mechanical properties and carrying out the necessary tests. After all, the method of manufacturing these products already presupposes the necessary heat treatment, which cannot be said about cold and heat-deformed products of GOST 9941.

The main difference between pipes GOST 9940 and 9941 is in mechanical properties. This is due precisely to the different methods of their manufacture.

Hot-deformed ones have greater flexibility and plasticity, but they are significantly inferior to cold- and heat-deformed ones in strength and resistance to physical stress exerted on them. So, the pipe 12X18H10T GOST 9940 has a tensile strength of at least 54 kgf / mm 2 (529 N / mm 2), but the relative elongation is not less than 40%. The products of GOST 9941 have 56 kgf / mm 2 (549 N / mm 2) and 35%, respectively.

In addition, for hot-deformed pipes 12X18H10T with a ratio of diameter to wall thickness equal to or less than 8, a reduction in tear resistance by 2 kgf / mm 2 (19.6 N / mm 2) is allowed. Products of GOST 9941 must withstand the rated load regardless of the geometric parameters of their section. Only the yield point for hot-deformed pipes is the same - 22 kgf / mm 2 (216 MPa). But this is due to the fact that the same stainless alloy is used for manufacturing - 12X18H10T.

Due to their greater strength, GOST 9941 pipes are made with smaller wall thicknesses and diameters than products of standard 9940. If we compare, for example, products with a diameter of 273, then cold and heat-deformed ones are produced with walls 3–14 mm, and hot-deformed ones - 11–20 mm ... Accordingly, the areas of application of GOST 9941 and 9940 products are somewhat different. The first is used where high strength of the pipeline or product is needed with its relative lightness, and the second, when the flexibility and ductility of the pipe from which they are made is more important when installing and operating a stainless network or part.

5 What is the secret of the prevalence of pipes 12X18H10T - the main characteristics of the alloy

Seamless pipes made of 12X18H10T are used more often than those made of other stainless alloys, and in the most different areas and industries, transport, utilities, as well as household services and so on. This versatility is made possible by the properties of the metal. The high prevalence of 12X18H10T products of GOST 9941 is also due to their physical and mechanical characteristics. But the latter also depend on the properties of the alloy used for the manufacture.

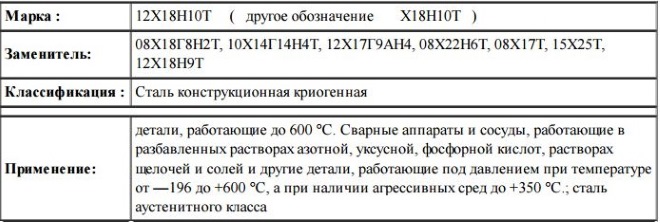

12Х18Н10Т refers to chromium-nickel. As stated above, chemical composition and the properties of this metal are regulated and described in GOST 5632, which applies to wrought alloys intended for use in corrosive conditions, environments and under the influence high temperatures.

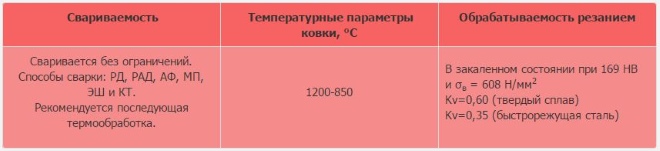

In addition, it is remarkably weldable by all types of automatic and manual welding, and also has good manufacturability during its hot plastic deformation. In the cold state, it allows rather high degrees of plastic deformation.

6 What technical characteristics and application of pipes provide alloy properties

Due to the first and, moreover, the predominant property of steel 12X18H10T, pipes made of it are resistant to chemical and electrochemical corrosion (soil, atmospheric, salt, alkaline and acidic), as well as intergranular corrosion, under stress and others. This alloy has the ability to passivate in an aggressive environment, which provides it with a sufficiently high immunity to its effects. So, an indicator of the anti-corrosion properties of steel 12X18H10T can be its resistance in:

- sulfuric acid (100%) heated to 65 ° C;

- 65% nitric acid solution heated to 85 ° C;

- 80% - heated to 65 ° C;

- 40% phosphoric acid solution heated to 100 ° C;

- mixtures of sulfuric and nitric acids (70% + 25% and 60% + 10%) heated to 70 ° C.

In addition, this alloy is highly resistant to solutions of various organic acids - citric, acetic, formic and others, as well as in strong alkalis - NaOH and KOH. Therefore, it is recommended to use 12X18H10T pipes as corrosion-resistant pipes for the manufacture of various welded fittings in various branches of the chemical and other industries.

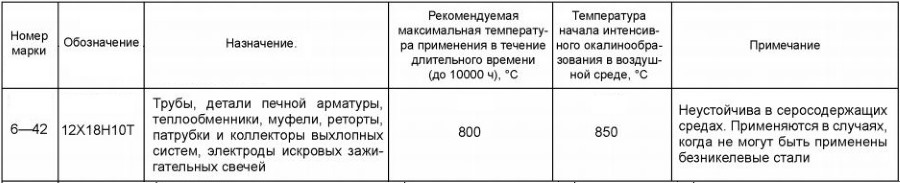

The heat resistance of steel ensures the resistance of the surface of pipes operating in a lightly loaded or unloaded state to chemical destruction in gas environments heated to temperatures above 550 ° C. For 12X18H10T, the maximum recommended application temperature for a long period of time - up to 10,000 hours - is 800 ° C. Intensive scale formation on the surface of a pipe made of this alloy in air begins at 850 ° C. However, steel 12X18H10T is unstable in environments containing sulfur.

In accordance with the characteristics of heat resistance, pipes made of 12X18H10T are recommended to be used as heat exchangers, parts and assemblies of furnace fittings, retorts, muffles, electrodes of incendiary spark plugs, collectors and branch pipes of exhaust systems. In addition, they are used when products from nickel-free alloys cannot be used.

The heat resistance of steel with sufficient heat resistance ensures the ability of the pipe to work for a certain time under the influence of high temperatures in a loaded state. For products made of 12X18H10T, the recommended operating temperature is 600 ° C. If this condition is met, the service life of the pipe is estimated as very long, that is, the time is much more than 10,000 hours (usually 50,000–100,000 hours). In accordance with the characteristics of heat resistance, products from 12X18H10T are recommended to be used as parts and pipes of exhaust systems, as well as other products operating in the modes for which the alloy is designed.

There are, of course, steels that have higher performance in comparison with 12X18H10T. But they have only one or two characteristics at the proper level, while others do not allow them to be used in the corresponding field of application - low corrosion resistance or heat resistance with heat resistance. Or in these alloys the content of alloying elements is higher. Therefore, their production and pipes from them are more expensive. As a result, and also in some cases based on the chemical composition of such steels, products made from the latter are, as a rule, intended for a narrower and more specific application in particularly difficult working conditions. That is why pipes made of 12X18H10T are the most common.

In addition to the above methods and areas of application of pipes made of this alloy, the following should also be indicated. They are used in: vessels, apparatus and pipelines operated under pressure at temperatures from –196 to +600 o C, and in aggressive environments - only up to +350 o C; petrochemical, food, cryogenic, pharmaceutical and chemical industries; automobile, aircraft, ship and mechanical engineering; cold and hot water supply systems (although this is not cheap); as a variety of design decorative elements and much more.

Interstate standard GOST 9941-81 regulates the assortment, technical requirements, acceptance rules, test methods, labeling, packaging, transportation and storage seamless pipes cold and heat deformed from corrosion resistant steel general purpose.

Assortment

According to GOST 9941-81, seamless stainless pipes are made with a diameter of 5 before 273 mm with wall thickness from 0.2 to 22 mm... The table below shows the maximum possible length for each size. The first column shows the outer diameter, and the header shows the wall thickness.

| Diameter | Maximum length with wall thickness | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.5 | 1.8 | 2 | 2.2 | 2.5 | 2.8 | 3 | 3.2 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | 11 | 12 | 14 | 16 | 18 | 20 | 22 | |

| 5 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||||||||

| 6 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||||

| 7 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||||

| 8 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||

| 9 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||

| 10 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 11 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 12 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 13 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 14 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 15 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 16 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 17 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 18 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 19 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 20 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 21 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 22 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 23 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 24 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 25 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 27 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 28 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 30 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 32 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 34 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 35 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 36 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||

| 38 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 40 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 42 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 45 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 48 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 50 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 51 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 53 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 54 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 56 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 57 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 60 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 63 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 65 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 68 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 70 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 73 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 75 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 76 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 80 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 83 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 85 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 89 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 90 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 95 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 100 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| 102 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| 108 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| 110 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 120 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 130 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| 140 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| 150 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| 160 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 170 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 180 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 200 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 220 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 250 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 273 mm. | 6.5 | 6.5 | 6 | 6 | 5.5 | 5.5 | 5 | 5 | 5 | 4 | 4 | |||||||||||||||||||||||||||

There are a number of notes on this table:

If the ratio of diameter to thickness is greater than or equal to 40, the pipe is considered thin-walled... Requirements for such a pipe in part technical characteristics and maximum deviations in size are established by the normative and technical documentation.

There are restrictions on the range depending on the steel used for production. If the product is made of steel grades 12X17, 08X17T, 15X25T, the outer diameter should not be less than 21 mm. For alloy 06ХН28МДТ, the outer diameter should be in the range from 14 to 85 mm and the wall thickness from 1 to 5 mm.

Limit deviations

The pipe production process on a rolling mill is technologically complex. The workpiece has to be molded to the size of a hollow sleeve and therefore often the nominal dimensions stated in the documentation do not correspond to the actual ones. GOST 9941-81 determines which deviations are acceptable. They make up:

| Pipe dimensions, mm | Limit deviations for manufacturing accuracy | ||

|---|---|---|---|

| the usual | increased | high | |

| Outside diameter | |||

| with a diameter of 5 to 10 | ± 0.3 mm | ± 0.2mm | ± 0.15mm |

| with a diameter of St. 10 to 30 | ± 0.4 mm | ± 0.3 mm | ± 0.2mm |

| with a diameter of St. 30 to 95 | ± 1.2% | ± 1.0% | ± 0.8% |

| with a diameter of St. 95 | ± 1.0% | ± 1.0% | ± 0.8% |

| By wall thickness | |||

| with a wall of 0.2 | ± 0.05mm | ± 0.03mm | - |

| with a wall from 0.3 to 0.4 | ± 0.07 mm | ± 0.05mm | - |

| with a wall from 0.5 to 0.6 | ± 0.10mm | ± 0.07 mm | - |

| with a wall from 0.7 to 1 | ± 0.15mm | ± 0.10mm | - |

| at the wall of St. 1 to 3 | +12,5% -15% | ± 12.5% | +12,5% -10% |

| at the wall of St. 3 to 7 | ± 12.5% | +12,5% -10% | ± 10% |

| at the wall of St. 7 | +12,5% -10% | ± 10% | - |

Pipes, highlighted in dark yellow in the table, are produced in only two categories of accuracy: normal and high. For them, other limit deviations have been established:

Also, unique limit deviations are set for pipes made of steel. 06ХН28МДТ... They are shown in the table below.

Usually pipes are made according to the outer diameter and wall thickness. But if the consumer wishes, GOST allows manufacturing according to the inner diameter and thickness. In this case, the permissible deviations are negotiated separately.

If the product turns out to be slightly oval, the ovality should not deduce the diameter beyond the maximum deviations in the outer diameter.

Deviations by curvature also installed. The curvature in any section 1 m long should not exceed:

- 1 mm- with a diameter of 5 mm or more, with a wall thickness of 0.5 mm or more;

- 2 mm- with a diameter of 15 mm or more, with a wall thickness of less than 0.5 mm.

- not regulated- with a diameter of less than 15 mm, with a wall thickness of less than 0.5 mm. These pipes should not have sharp bends.

Calculation of pipe weight

Often the consumer is faced with the need to calculate weight of a running meter of pipe... This can be done using special calculators for rolled metal products, which can be found on our website or on many other specialized sites on the Internet. The standard specifies the following weight calculation formula:

Mass = 3.14 / 1000 * ((Diameter - Thickness) * Thickness * Density)

The mass of a meter is usually measured in kilograms. For calculations, the density of the steel must be taken from the following table.

| steel grade | Temporary resistance | Relative extension | Density |

|---|---|---|---|

| not less | |||

| 08Х17Т | 372 (38) | 17 | 7,70 |

| 08X13 | 372 (38) | 22 | 7,70 |

| 12X13 | 392 (40) | 22 | 7,70 |

| 12X17 | 441 (45) | 17 | 7,70 |

| 15X25T | 461 (47) | 17 | 7,60 |

| 04X18H10 | 490 (50) | 45 | 7,90 |

| 08Х20Н14С2 | 510 (52) | 35 | 7,70 |

| 10Х17Н13М2Т | 529 (54) | 35 | 8,00 |

| 08Х18Н12Б | 529 (54) | 37 | 7,90 |

| 10X23H18 | 529 (54) | 35 | 7,95 |

| 08X18H10 | 529 (54) | 37 | 7,90 |

| 08X18H10T | 549 (56) | 37 | 7,90 |

| 08Х18Н12Т | 549 (56) | 37 | 7,95 |

| 08Х17Н15М3Т | 549 (56) | 35 | 8,10 |

| 12X18H10T | 549 (56) | 35 | 7,95 |

| 12Х18Н12Т | 549 (56) | 35 | 7,90 |

| 12X18H9 | 549 (56) | 37 | 7,90 |

| 17Х18Н9 | 568 (58) | 35 | 7,90 |

| 08Х22Н6Т | 588 (60) | 20 | 7,60 |

| 06ХН28МДТ | 490 (50) | 30 | 7,96 |

All calculated values for stainless seamless pipes in our database are produced taking into account these requirements according to the above formula! The density of steel for basic calculations was taken equal to 7.85, which corresponds to the standards of GOST.

Length

Often the buyer has a question regarding length... The standard on this matter indicates that it is allowed to manufacture pipes:

- Measured length- within the bounds of unmeasured. In this case, the length should not exceed the values specified in table 1 of GOST. In this case, the deviation in length should not exceed +15 mm. It is allowed to manufacture pipes longer than the specified values, but only with the appropriate agreement between the manufacturer and the consumer.

- Lengths, multiples of the measured- within the measured. In this case, allowances of 5 mm are allowed for each cut. Length deviation should not be more than 15 mm

- off-gauge length with wall thickness up to 0.5- it is allowed to manufacture pipes with a length of 0.75 meters to the value indicated in Table 1. At the same time, no more than 6% of products with a length of 0.5 to 0.75 meters are allowed in a batch.

- off-gauge length with wall thickness from 0.5 to 1 mm- it is allowed to manufacture pipes with a length from 1 meter to the value indicated in Table 1. At the same time, no more than 6% of products with a length from 0.75 to 1 meter are allowed in a batch.

- off-gauge length with a wall thickness of more than 1 mm- minimum length 1.5 meters, maximum length 12.5 meters. At the same time, no more than 6% of products with a length of 0.75 to 1.5 meters are allowed in a batch.

It is possible to produce pipes with a length of more than 12.5 meters, but only in case of agreement between the manufacturer and the buyer.

In case of agreement on the issue of pipes with a length exceeding those specified in Table 1, it must be remembered that pipes with a diameter of up to 25 mm cannot be longer than 16 meters.

Difference from hot-deformed

In accordance with this standard, pipes are produced by the method cold or warm deformation... As you know, there are stainless seamless pipes made by GOST 9940-81 by hot rolling. The difference from cold-deformed is the manufacturing method. In cold deformation, the workpiece is formed without preheating to a high temperature. Since there is no heating, the resulting pipe does not undergo temperature deformations and, as a result, comes out more accurate and uniform.

Actual dimensions of pipes produced according to GOST 9941-81 are much more accurate than hot forming. Dimensional tolerances are generally less. Therefore, if for the purposes of the project you need increased manufacturing accuracy, choose cold-rolled products.

The main disadvantage of such pipes is their higher price... They are usually more expensive than hot rolled. However, some projects require just such items. Therefore, if manufacturing accuracy is not a critical factor for a project, it is more expedient to give preference to hot-deformed ones due to their lower price.

Istroia

This standard was developed and introduced by the Ministry of Ferrous Metallurgy of the USSR. Although it was adopted back in the days of the USSR, it is still in effect. The expiration date was lifted by the Interstate Council for Standardization, Metrology and Certification Russian Federation in protocol N 2-92. The last amendment to it was adopted in 2000, and the last amendment in 2011.

Requirements for seamless pipes made of of stainless steel made by cold or hot rolling, imply the use of a limited number of alloys, which are fixed by GOSTs.

One of the methods for the production of stainless steel pipes is the seamless method. The final product is obtained from a pipe billet as a result of chemical and heat treatment, a sequence of mechanical deformations. According to the content of the production process, seamless pipe is manufactured using cold or hot rolling technology.

Cold and heat deformed seamless stainless steel pipes

Cold process technology has significant advantages:

- Minimal metal loss.

- Possibility of obtaining a wide range of standard sizes of pipes from the same type of workpieces.

- Allows to produce products with a wall from 0.2 mm.

- Minimization of deviations in wall thickness.

- Excellent surface quality of finished products.

- Durability.

Requirements for pipes in accordance with GOST 9941-81

The surface of the products should not have cracks, captivity, sunsets. External damages resulting from the backing deformation are subject to cleaning (grinding) without going beyond the standard limits. These indicators are reflected in tables 1 and 2.

For products of sizes (diameter x wall thickness, mm):

- 100-102 x 1.5-2.9;

- 108-120 x 1.5-3.2;

- 130-150 x 2-3.2;

- 160-200 x 2.5-3.5;

- 220 x 3-3.5;

- 250 x 3-4 -

limit deviations are specified specially and are given in table 3.

The standard specifies requirements for the curvature parameter of products produced by a seamless cold-rolled method. This value is indicated per 1 m of pipe and is for the diameter:

- less than 15 mm: 1 mm.

- more than 15 mm: 2 mm.

For products with a diameter of up to 15 mm and a wall of up to 0.5 mm, the limiting curvature is not set by the standard: it can be any, without bends.

The surface of the pipes is light. The peculiarities of the production process and the grade of the metal can give a dull color.

Cold-worked tubular products must withstand a number of tests:

- tension at a temperature of 350 degrees C;

- flattening / spreading to calculated parameters;

- hydraulic pressure at 40% tensile strength of steel type;

- for intergranular corrosion;

- ultrasonic testing.

Cold Rolled Steel Pipe Technology

Deformation of the workpieces is preceded by chemical preparation - etching. Steel with alloying chromium content is etched with alkaline melts and acid solutions. The result is the transformation and removal of iron oxides and scale.

Then the pipes are washed hot and cold water, dried at a temperature of 170 degrees C, special coatings are applied to prevent the occurrence of defects with further deformations. When rolling through the mill, the workpieces do not come into direct contact with the tooling tools.

The workpieces go through rolling mills repeatedly. In the intermediate stages, they are exposed to additional chemical influences. Heat treatment up to 700-800 degrees C plays a significant role, as a result of which the hardness of the metal decreases (annealing). After deformations, thermal hardening is carried out, as a result of which the mechanical properties of the products increase.

Sizes of seamless pipes according to GOST 9941-81 - table

Hot Rolled Seamless Steel Tubes

The hot process technology endows the finished product with the following advantages:

- Ideal anti-corrosion properties.

- Durability and resistance to impacts.

- Allows to manufacture products with a wall up to 32 mm.

- Competitive price.

Standards for pipes according to GOST 9940-81

Hot-deformed pipes are cleaned from scale, do not have external defects on both surfaces. If the products are subject to further welding, then the normatively restricts the mass fraction of sulfur in the material - 0.02%.

The curvature of the finished hot-deformed products is established by the normative. This value is indicated relative to the wall thickness per 1 m of pipe and is:

- with a wall less than or equal to 10 mm: 1.5 mm;

- with a wall of 10-20 mm: 2 mm;

- with a wall of more than 20 mm: 4 mm.

Requirements of the standard for passing hydraulic test, tensile test and others - similar to the tests established for products produced by the cold-worked method.

Hot rolled steel technology

Unlike the cold rolling method, which provides for heat treatment of blanks and products at some stages, the hot rolling method is completely carried out on heated metal. For this purpose, special furnaces with the so-called walking hearth are used, in which an overpressure of up to 29.4 Pa is formed.

- crimping mill;

- a piercing mill in which the workpiece becomes a walled pipe;

- rolling on a continuous mill;

- induction heating and reduction station.

After reduction, the finished pipes are cooled and cut to the required lengths.

Sizes of seamless pipes GOST 9940-81 - table

GOST introduced additional restrictions on the diameter of products for some steel grades:

- 108 mm - 08Х20Н14С2, 08Х22Н6Т, 08Х18Н12Б.

- 140 mm - 08Х17Н15М3Т.

- 168 mm - 10X23H18.

- 219 mm - 10X17H13M2T, 15X28, 08X17T, 12X17.

Main grades of stainless steel for seamless pipes

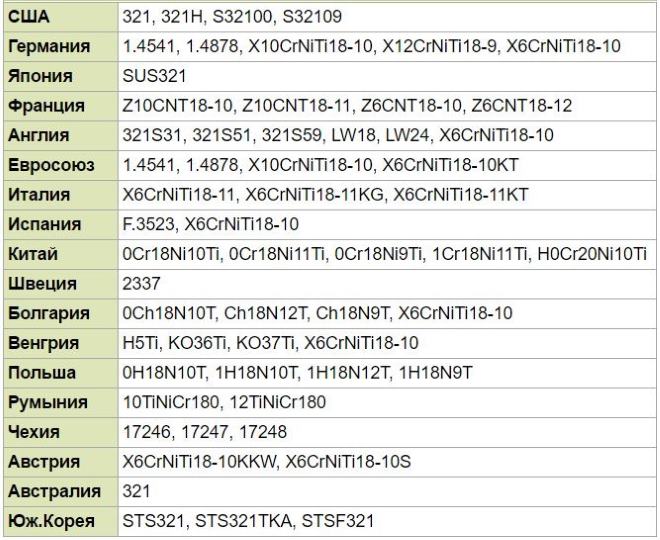

GOST 9940 and 9941 contain 20 grades of alloys that can be used for the manufacture of stainless steel seamless pipes... Of these, the most used are presented below.

Steel 12x18n10t

The steel has excellent anti-corrosion properties, is resistant to oxidation at temperatures up to 900 degrees C, and has high heat resistance.

Properties of pipes made of steel 12x18n10t by cold / hot rolling:

- resistance, kgf / sq.mm: 56/54;

- elongation,%: 35/40;

- density, g / cc: 7.95 / 7.9.

Tubular products made of this steel are used for the transportation of oxidizing media, organic solvents and some types of organic acids, in cryogenic technologies at temperatures close to absolute zero.

Steel grade 08x18n10t

The stainless steel of this brand is characterized by even better properties for the transportation of aggressive media than the previous type. It finds its application in the chemical industry as exhibiting high parameters of resistance to intergranular corrosion.

Mechanical properties of pipe products made of steel 08X18H10T by cold / hot rolling:

- resistance, kgf / sq.mm: 54/52;

- elongation,%: 37/40;

- density, g / cc: 7.9.

Pipes made of this type of steel can be operated at any pressure and temperature up to 600 degrees C.

Steel 10х17Н13М2Т

The type of steel contains 3% molybdenum, which gives it additional properties that steels 12x18 and 08x18 lack. Pipes made of 10x17H13M2T are resistant to chlorine. In acidic environments, depending on the type of acid, its concentration and temperature, the annual corrosion rate does not exceed 0.1 mm. The mechanical properties of products manufactured from 10x17N13M2T by cold and hot rolling are the same and are:

- resistance, kgf / sq.mm: 54;

- elongation,%: 35;

- density, g / cc: 8

Steel grade 06хН28МДТ

Stainless steel contains molybdenum (up to 3%), an increased amount of nickel (up to 29%) and chromium (up to 25%). It is used in industrial installations requiring the transportation of acids and other aggressive media. In accordance with the standard, this steel grade is used in the production of pipes using the cold rolled method. The mechanical properties of the products are as follows:

- resistance, kgf / sq.mm: 50;

- elongation,%: 30;

- density, g / cc: 7.96

For cold rolled pipes made of 06xH28MDT, special permissible deviations in diameter and wall are established (table 8).

Steel 10х23Н18

Refers to a group of heat-resistant alloys. It can be used to work with aggressive environments with temperatures up to 1000 degrees C. At higher temperatures in the air, it is subject to intense oxidation.

Properties of pipes manufactured from 08x18n10t by cold / hot rolling:

- resistance, kgf / sq. mm: 54/50;

- elongation,%: 35/37;

- density, g / cc: 7.95.

Transported under high pressure environments at temperatures up to 1000 degrees C lead to a reduction in the service life of products to 1-10 thousand hours.

Scope of application of seamless steel pipes

Seamless technology is one of the main methods of making thin-walled and thick-walled stainless tubes with precise bore. They are applied:

- in high pressure installations;

- in power plants;

- in mechanical engineering and aviation industry;

- in the chemical and food industry;

- in gas and oil pipelines.

The scope of their application is wide and covers highly specialized types of production and industry.

Electro-welded stainless steel pipes

The second method for the production of stainless steel tubing is the simpler and more economical electro-welded method.

Welded pipe fabrication methods

The main difference between the welded method and the seamless one is that it provides for the manufacture of a pipe not from a finished billet by means of numerous deformations, heat and chemical treatments, but welding of a steel sheet bent into a pipe. Further, water cooling, calibration, cutting, control measures are carried out. If necessary, carry out the back deformation.

Significant reduction in production costs stainless products welded made it possible to use them in everyday life: for pipelines, for decorative and construction purposes.

Yulia Petrichenko, expert

Regulatory documents for welded stainless steel pipes

Specifications for electrowelded products made of anti-corrosion steel are set out in GOST 11068-81. Specification shaped pipes square and rectangular forms are contained in GOST 8639-82 and GOST 8645-68, respectively.

Sizes of electrowelded stainless steel pipes

| Outside diameter, mm | Wall thickness, mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,8 | 1,0 | 1,2 | 1,4 | 1,5 | 1,8 | 2,0 | 2,2 | 2,5 | (2,8) | 3,0 | (3,2) | 3,5 | 4,0 | |

| 8 | NS | NS | NS | - | - | - | - | - | - | - | - | - | - | - |

| 9 | NS | NS | NS | - | - | - | - | - | - | - | - | - | - | - |

| 10 | NS | NS | NS | - | - | - | - | - | - | - | - | - | - | - |

| 11 | - | NS | NS | NS | NS | NS | - | - | - | - | - | - | - | - |

| 12 | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - | - |

| 14 | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - | - | - |

| 15 | - | NS | NS | NS | NS | NS | - | - | - | - | - | - | - | - |

| 16 | NS | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - |

| (17) | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - |

| 18 | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - |

| (19) | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - |

| 20 | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - |

| 22 | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - | - |

| 25 | - | NS | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - |

| 28 | - | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - |

| 30 | - | - | NS | NS | NS | NS | NS | NS | NS | - | - | - | - | - |

| 32 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 33 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 34 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 35 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 36 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 38 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 40 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 42 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 43 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 45 | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 48 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 50 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 51 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 53 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 55 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 56 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 57 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 60 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 63 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | - | - |

| 65 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS |

| 70 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS |

| 76 | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS |

| 83 | - | - | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS |

| 89 | - | - | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS |

| 102 | - | - | - | - | - | NS | NS | NS | NS | NS | NS | NS | NS | NS |

The off-gauge length of electrically welded pipe products can range from 1.5 to 9 m. The measured length should be within 5-9 m.

Seamless stainless pipes are reliable products with wide application. Their cost is higher than that of welded counterparts, which are more suitable for domestic use.

Have you ever dealt with seamless pipes? What steel grades, in your opinion, are the most in demand? Share your opinion in the comments.

Expertise - estimate engineer

Ask an expert

Stainless steel pipe seamless GOST 9941-81, 9940-8 from steel 12x18n10t, 08x18n10t - requirements for products, dimensions - print version

Seamless stainless steel pipe made in accordance with GOST 9941-81 from steel grade 12X18H10T is one of the most popular types of products of this type. The high popularity of seamless stainless steel pipes of this brand is due to the wide versatility of their characteristics.

Such pipes can be successfully used to solve a wide range of problems associated with the need to transport liquid and gaseous media. Due to the properties of 12X18H10T steel, products made from it can be successfully operated under conditions of constant exposure to high pressure and high temperature, as well as contact with chemically aggressive substances for a long time, without losing their original characteristics.

You can get acquainted with the GOST requirements for seamless stainless pipes by downloading the pdf document from the link below.

GOST 9941-81 Seamless cold- and heat-deformed pipes made of corrosion-resistant steel. Technical conditions

Types of seamless pipes made of steel grade 12X18H10T

The requirements of GOST 9941-81 include not only pipes 12X18H10T, but also seamless tubular products manufactured by cold and warm deformation from other grades of general-purpose stainless steels. According to the provisions of the specified GOST, the assortment of such pipes is made up of products, the outer diameter of which is in the range of 5-273 mm, and the walls have a thickness of two tenths to twenty two mm. The requirements of GOST 9941-81 concern not only the geometric parameters of seamless stainless steel pipes, but also the technical characteristics of such products.

The permissible length of stainless steel pipes transferred to the warehouse or to consumers, which is also stipulated by GOST, is determined by their outer diameter and wall thickness.

In the standard version, this parameter can be in the range of 4–7 m, but GOST 9941-81 also allows that seamless stainless steel pipes can be supplied to consumers in the following lengths.

- Pipes, the wall thickness of which does not exceed half a millimeter, have an unmeasured length. Moreover, the minimum length of such pipes cannot be less than 0.75 m, and the maximum must not exceed the largest standard value.

- Tubular products with a wall thickness in the range of 0.5-1 mm are made of unmeasured length, the value of which does not go beyond 1 meter and the maximum standard value.

- Pipes with a wall thickness of more than 1 mm have an unmeasured length, the value of which is in the range of 1.5–12.5 m.

- They also produce stainless steel pipes of measured length, the minimum value of which does not go beyond the lengths of off-gauge products, and the maximum value - beyond the maximum length specified by GOST. For rolled pipes, the length of which corresponds to this category, the maximum maximum deviation of this parameter should not exceed 15 mm. The regulatory document allows that the length of the measuring pipes may be greater than the parameters specified in the standard, but for the production of such products, a preliminary agreement between the manufacturer and the consumer is required.

- There are pipes with a length that is a multiple of the measured one, while the smallest value of such a multiplicity, in accordance with the provisions of GOST 9941-81, is 300 mm. In the production of such rolled pipes, it is allowed to leave an allowance on each side of the cut, the value of which should not exceed 5 mm. In addition, the standard specifies the maximum deviation from the total length of such products, which should not exceed +15 mm.

- If the consumer has a need for stainless pipes, the length of which exceeds 12.5 m, GOST allows the possibility of their manufacture, but this must also be previously agreed with the manufacturer.

- Tubular products, the outer diameter of which does not exceed 25 mm, can be produced with a length of up to 16 m by agreement between the customer and its manufacturer.

GOST 9941-81 classifies pipes 12X18H10T and products made of other steel grades, not only by their length options and other geometric parameters, but also by their degree of accuracy. So, seamless type pipes made of stainless steel alloys can correspond to conventional, high and high accuracy.

The geometric parameters of seamless pipe products are associated with the maximum deviations of the thickness of their walls, as well as the outer diameter. GOST 9941-81 also regulates the value of the permissible curvature of pipe-rolling in a seamless category, which, if measured on a piece of pipe 1 meter long, cannot exceed:

- 1 mm - for pipes of any diameter, the wall thickness of which is half a millimeter or more;

- 2 mm - for pipes with a wall thickness of less than half a millimeter and an outer diameter exceeding 15 mm.

For stainless seamless pipes with an outer diameter of less than 15 mm, the wall thickness of which does not exceed half a millimeter, such a parameter as the value of the permissible curvature is not specified in the standard. The only requirement is that there should be no sharp bends on their surface.

The ends of seamless pipes, according to GOST 9941-81, must be cut strictly at an angle of 90 °, and after such a cut, they must be deburred. During cleaning, roughness and chamfer may form on the surface of the pipes, the presence of which is allowed by the standard. The consumer of pipes, the wall thickness of which exceeds 5 mm, can, if necessary, indicate that their cut ends must be specially chamfered for welding.

Formula for calculating mass

In the provisions of GOST 9941-81, there is no exact information about how much one running meter of a seamless stainless pipe weighs. This is explained by the fact that the requirements of this standard include a range of seamless pipes, for the manufacture of which about 20 grades of general-purpose stainless steels can be used.

Meanwhile, this GOST presents a formula, using which, you can easily determine the specific weight of a pipe with certain geometric parameters.

For convenience, the GOST lists the density values of all steel grades from which pipes of this category are made. In particular, for 12X18H10T this parameter is 7.9 g / cm 3. As an example, we can determine the weight of one running meter of a seamless pipe from a given brand:

M = 3.14 / 1000 × (50-4) × 4 × 7.9 = 4.56 kg.

Using the weight of one running meter of a stainless pipe, calculated by this formula, you can easily determine how much a product with a certain length will weigh. To do this, it is enough to multiply the resulting weight by the total length of the pipe roll.

Main characteristics

The chemical composition of steel alloy 12X18H10T, from which seamless pipes are made, are stipulated by the requirements of GOST under number 5632. According to the provisions of this regulatory document, such steel (if, at the request of the customer, must have good weldability) cannot contain more than 0.02% of such harmful impurities like sulfur. In accordance with the standard, elements of the rare earth group may be included in the chemical composition of stainless steel of this grade in small quantities.

Despite the fact that seamless pipe-rolling must be subjected to heat treatment, it is admitted in GOST that it is possible to do without it, as well as without the procedure for lightening the surface. In such cases, it is necessary to additionally discuss with the consumer both the mechanical properties of the pipes and the permissible degree of curvature of their surface.

The high popularity of seamless pipes made of stainless steel alloy 12X18H10T is explained by the fact that they are considered one of the best in terms of their mechanical properties and performance characteristics.

The mechanical properties, in particular, include the following parameters of the steel alloy of this brand:

- yield point - not less than 22 kgf / mm 2 (216 MPa) (this parameter, which is very important for steels, characterizes the amount of stress, upon reaching which deformation processes occurring in the metal will continue to develop in it even without a subsequent increase in the load);

- tensile strength - 56 kgf / mm 2 (549 N / mm 2);

- the value of the relative elongation is not less than 35%.

At the request of the customer, tensile tests of seamless stainless steel pipes can be carried out at 350 °.

Inside and outside of pipes made of stainless steel of the specified grade, there should be no defects such as cracks, trapping, flaws and sunsets. If they are found after control, then, according to the regulatory document, they can be eliminated using local cleaning, turning and boring, local or continuous grinding. When performing such mechanical operations, it is important to ensure that the geometric parameters of the pipe, such as wall thickness and outer diameter, are not, as a result, outside the deviations specified in GOST.

The provisions of the regulatory document also stipulate the color of seamless stainless steel pipes, which should be light. At the same time, individual pipe products of this category may have a matte surface, which is distinguished by a gray tint, which is due to the peculiarities of their production technology. The main part of pipes of this type is subjected to vacuum etching or in a protective environment, which is carried out after heat treatment. Such processing (as mentioned above, optional) is performed in order to eliminate tarnishing from the surface of the product.

In accordance with the provisions of the regulatory document, seamless pipes made of steel alloy grade 12X18H10T, at the request of consumers, can be subjected to additional tests for:

- flattening;

- distribution;

- ability to withstand hydraulic pressure.

In addition, in a separate clause of the contract concluded between the manufacturer and the consumer, a requirement may be specified, according to which the pipe material must be highly resistant to intergranular corrosion.

In the event that seamless pipes made of this steel alloy were not subjected to heat treatment and they were not tested by flattening or expansion methods, then they are not tested for resistance to intergranular corrosion.

Requirements of GOST 9940-81

Stainless steel alloy 12X18H10T is also used for the production of seamless pipes in accordance with GOST 9940-81. According to this normative document, seamless tubular products are manufactured by the hot deformation method, for which general purpose stainless steels are used.

Seamless pipes manufactured in accordance with GOST 9940-81 can have diameters in the range of 57–325 mm and a wall thickness of 3.5–32 mm. The standard length of such pipes, which can correspond to the usual and high degree accuracy, can be from 3 to 8.5 meters. The provisions of GOST 9940-81 also stipulate the rest of the geometric parameters of pipes of this category, the physical and mechanical properties of the material from which they are made, the maximum permissible deviations of the curvature of the surface of products, their outer diameter and wall thickness.

![]()

According to the requirements for the chemical composition of the material for the manufacture of seamless stainless pipes, GOST 9940-81 differs little from the provisions of the previous regulatory document. You can determine the mass of pipes using the same method as presented above.

State standard numbered 9940-81 provides that seamless pipes made of stainless steel, depending on the wishes of the customer, may or may not undergo heat treatment, meet additional requirements for their resistance to intergranular corrosion. In addition, consumers of pipes of this type can additionally negotiate with their manufacturer the test methods for such products, which are carried out according to the methods specified in the provisions of GOST 9941-81.

A significant difference between GOST 9940-81 and the standard under the number 9941-81 is that its requirements do not provide for mandatory heat treatment of seamless stainless pipes. This is explained by the fact that pipes that comply with this standard, as already mentioned above, are produced by the method of hot deformation, and this already suggests that the material of their manufacture was subjected to significant thermal stress. The latter is necessary to facilitate plastic deformation of the pipe material and at the same time gives it the required physical and mechanical properties.

It should be noted that the differences in the characteristics of seamless stainless pipes produced according to GOST 9940-81 and 9941-81 are precisely explained by different manufacturing technologies. So, seamless stainless steel pipes, obtained by the method of hot deformation, are distinguished by good plasticity and flexibility, but have less strength and resistance to mechanical stress than cold and heat-deformed ones. For example, you can compare the following parameters of pipes made of stainless steel alloy grade 12X18H10T, produced in accordance with GOST 9940-81 and 9941-81:

Due to the increased strength, seamless stainless pipes manufactured by cold and warm deformation methods, regardless of their geometric parameters, must withstand the nominal load provided for by the requirements of the regulatory document. This explains why the pipe-roll of this category can be produced with smaller outer diameters and wall thicknesses than products manufactured in accordance with GOST 9940-81. So, if we compare cold and heat-deformed pipes with hot-rolled products of the same outer diameter (273 mm) made of stainless steel 12X18H10T, then the former can be produced with a wall thickness of 3–14 mm, while for the latter this parameter should be 11–20 mm. At the same time, the yield points of such products, since they are made of steel of the same grade, completely coincide and amount to 22 kgf / mm 2 (216 MPa).

From the foregoing, it can be concluded that cold and heat-deformed seamless pipes made from steel grade 12X18H10T are more expedient to use in cases where high strength is required with a low weight of pipe structures, and hot-rolled products will be optimal when especially important properties are the flexibility and ductility of the pipes used.

Reasons for the popularity of pipes 12X18H10T

Seamless pipes made of steel grade 12X18H10T are in high demand. They are widely used in mechanical engineering, fuel, energy, food, chemical and other industries. The main reasons for this popularity lie in the physical and mechanical properties of this alloy, determined, first of all, by its chemical composition.

Stainless alloy grade 12X18H10T is a material with an austenitic structure, belonging to the steels of the chromium-nickel category. According to the provisions of GOST, it is intended for operation under conditions of constant exposure to chemically aggressive media and high temperatures.

If you decipher the marking of this steel alloy, it will become clear that its composition contains the following chemical elements: carbon - 0.12%, chromium - 17-19%, nickel - 9-11%, titanium - 5%. In addition, this grade of stainless steel also contains silicon (0.8%) and manganese (2%). Due to such a balanced chemical composition, the steel alloy of this grade is distinguished not only by high corrosion resistance, but also by heat resistance and heat resistance.

In addition, the advantages of this brand of steel, from which seamless pipes are made using various technologies, are:

- good weldability;

- the ability to perform processing by methods of both hot and cold deformation.

Spheres of application of pipe-rolling from steel 12X18H10T

The unique chemical composition, as well as other properties of the 12X18H10T stainless steel alloy make it resistant to intergranular corrosion, as well as corrosion caused by:

- chemicals (salts, alkalis, acids);

- soil and humid atmosphere.

The main advantage of the alloy of this brand is that products made of it practically do not lend themselves to the influence of aggressive media, which allows them to be successfully used even in the most difficult conditions. Visual indicators of the extremely high corrosion resistance of steel of the considered grade is that products from it are effectively used even in such aggressive environments as:

- sulfuric acid with a concentration of 100%, heated to 65 °;

- 65% nitric acid solution, heated to 85 °;

- 80% nitric acid solution, heated to 65 °;

- a solution of phosphoric acid with a concentration of 40%, heated to 100 °;

- a solution consisting of sulfuric and nitric acids in the ratio of 70 + 25% or 60 + 10%, respectively, heated to 70 °;

- solutions of organic acids (such as acetic, citric, formic, etc.);

- solutions of strong alkalis (NaOH and KOH).

Due to such unique properties, steel alloy 12X18H10T is recommended to be used for the manufacture of tubular products and welded fittings used in chemical, oil refining and other industries.

Such a property of a steel alloy of this grade, as heat resistance, ensures the resistance of the surface of pipes that are made of it to chemical destruction when operating in gaseous environments, the temperature of which exceeds 550 °. It should be borne in mind that such stability is possible when the pipes are operated in an unloaded or lightly loaded state.

The temperature of the gas environment at which a pipe made of steel 12X18H10T can be operated for 10,000 hours without compromising its quality should not exceed 800 °. If the air temperature is raised to at least 85 ° degrees, then on the surface of such a stainless pipe, intensive scale formation will begin. Steel of this grade exhibits rather low resistance in environments containing sulfur.

The level of heat resistance of seamless stainless pipes made of steel alloy 12X18H10T determines the scope of their application. So, they are used for making:

- various elements of furnace fittings;

- heat exchangers;

- muffles;

- retorts;

- electrodes for equipping incendiary spark plugs;

- elements of exhaust systems (collectors and pipes).

In addition, such pipes are used when it is not possible to use products made of nickel-free steel alloys.

As mentioned above, stainless steel 12X18H10T also differs in heat resistance, which makes it possible to successfully use products from this material in situations where they are exposed for a long time not only to high temperatures, but also to mechanical loads. The parameters of the heat resistance, which the steels of this brand have, make it possible, under certain conditions, to use products made of them from 50 to 100 thousand hours.

It should be borne in mind that the optimal temperature at which such a period of operation can be maintained is 600 °. As heat resistant alloy 12Х18Н10Т steel can be used for the manufacture of elements of exhaust systems, as well as other products, the operating conditions of which do not go beyond the permissible limits for this material.

On the modern market, there is a wide variety of stainless steels, the individual parameters of which can exceed the properties of the 12X18H10T alloy. In particular, 14X2 steel is a very popular material, from which seamless cold-worked pipes are also made. However, in most cases, all such alloys are distinguished by one or two outstanding characteristics, and there is no need to talk about the universality of their application. That is why products made of such steel alloys can be used only in highly specialized areas, while pipes and other products, for the manufacture of which stainless steel 12X18H10T was used, can be used almost everywhere.

The advantages of using seamless pipes made of stainless steel alloy 12X18H10T are also evidenced by the fact that such products can be successfully operated under pressure and with prolonged exposure to temperatures from -196 to + 600 ° on their surface. However, this is possible if such pipes do not come into contact with aggressive media. Otherwise, the upper temperature limit at which the pipes will not lose their original characteristics for a long time is reduced to + 350 °.

It should also be borne in mind that the cost of seamless pipes made of stainless steel of this grade is quite high, therefore it is advisable to use them in cases where the products used are required increased reliability and extremely high corrosion resistance.

2, average rating: 5,00

out of 5)