Geysers are designed to heat water in an apartment and a house in which there is no hot water supply. They're in Lately have become popular heating appliances among the population, both private houses and residential apartments. They are often bought by families with children, as in our time there are more and more interruptions in the supply of hot water.

The most popular models of gas water heaters are easy to operate, they are safe and quickly allow you to adjust the degree of heating of water in the house. In this article, we will analyze how the Junkers gas column works and how it is repaired. .

1 Advantages of the gas column Junkers

Almost all Junkers wr 10 gas water heaters and Junkers wr 275 gas water heaters are adapted for countries such as Russia. These heating devices have their own advantages, such as:

- They are adapted to a gas pressure of 13 Mbar for Russia. Compared to Europe, there the pressure in the gas pipeline reaches 20 Mbar. If your Junkers column is not adapted to gas pressure, then it may be less productive. And this moment is important.

- In multi-storey houses, the Junkers gas water heater can work stably at a pressure of 0.1 ATM. And this is a very good indicator.

- The device of the Junkers gas column is made in such a way that such heating devices can heat from 11-20 liters of water per minute. It should also be noted that in these columns, water can itself be mixed in the mixer.

- The Junkers geyser has flame modulation, which allows it to automatically change power depending on the water supplied.

- It has a high-quality German assembly and a 2-year warranty for the device, as well as a long service life, unless of course you follow all the safety and use rules.

- The low price of Junkers geysers, unlike its counterparts.

2 Types and prices for geysers of the Junkers brand

All geysers of the German manufacturer Junkers are divided into three types according to the ignition method. Such speakers with the types listed below can be easily ordered from an authorized dealer, as well as in a specialized store. They are affordable, and you will always find spare parts for them in stock. The German manufacturer tried and invented this column for people with a low budget.

Series B includes columns that do not have a burning igniter. In such columns, ignition occurs with the help of batteries. The Junkers column in this case turns on automatically and has several security systems such as:

- Controls traction.

- The presence of a fuse in the device.

- Flame adjustment ionization.

- The presence of a malfunction indicator in the device.

But the flow of water in this type of column is regulated depending on the pressure that you have in the tap (water supply). Almost all Junkers Bosch gas water heaters are made of high quality copper. Service life not less than 10-15 years. Also, you will meet only positive reviews about the Junkers geyser.

The P series includes piezo ignition columns. In this case, the igniter burns constantly when the column is turned on. In this series, the water flow is regulated separately. But flame control is only thermoelectric. The Junkers gas column instruction of this type is complex and requires additional study.

Series G - ignition works with the help of technology such as "Hydro Power". In these columns, the minimum water pressure reaches 0.35 ATM. It does not have a burning igniter.

Such a column from the generator provides ignition. The column can simultaneously provide up to three water points. These models are available in two sizes (types) standard and mini.

They have the same equipment. The price only varies depending on the size of the column. That and spare parts for speakers can also be found in any specialty store.

2.1 Possible breakdowns of UNECRS gas water heaters

You bought a geyser, it served you quite a bit, and suddenly it stops working. In this article we will talk about the malfunction of Junkers geysers. Yes, surprisingly, they break too.

Junkers gas column does not ignite.

First you need to make sure that the igniter is on in the column. If for some reason the igniter does not burn, then you need to call the gas service. Or clean the igniter yourself with your own hands. In this case, the jet is cleaned in the igniter. It may also be that the gas supply is not supplied, but here it should be visible on the column indicator.

Another reason that the geyser does not ignite may be that you do not have draft in the ventilation well. It is very easy to check if there is draft in the ventilation shaft.

A sheet of paper is leaned against the exit of the ventilation well, or a burning match can be brought up. If you find that there is no draft in the well, then you can clean it with your own hands. Suddenly you do not want to clean the ventilation well yourself, it is better to call the gasmen.

Another reason that the Junkers geyser does not ignite may be that the water membrane that is inside the equipment has failed. If your column is old, has been in use for a long time, then over time the membrane is deformed from loads. It can tear and fray. It should be noted that the membrane is not repairable, it must be replaced.

We also recommend that when disassembling the heater, pay attention to the filter, which is located in the water intake of the heater. The water filter can be replaced with your own hands, without requiring the call of a master from the gas service.

The next breakdown is when the Junkers gas column goes out.

If you turn on the geyser, and when it works, it goes out abruptly, then the matter is in the temperature sensor, which is responsible for overheating the geyser. A sign of a non-working temperature sensor is that the burner is turned on, burns and abruptly goes out after a while.

You are trying to kindle but it does not give results. After about a few minutes, the gas heater can be switched on again. The column works, and then goes out again.

This is due to the sensitivity of the sensor. It may also be that the column is turned off due to the wear of the insulation of the sensor conductor. In this case, the wire is exposed and it touches the case, which is why a short to the case occurs. In this case, the safety valve is activated.

The column emits pops during operation.

There can be many reasons. Here are some of them:

- Too strong initial gas pressure. The Junkers column ignites and burns very actively, because of this, cotton (flame failure) occurs.

- The gas pressure is weak, as a result of which air enters the inside of the device and cotton occurs.

In these cases, the Junkers geyser requires cleaning and adjustment by an experienced craftsman. Also, when cleaning and troubleshooting, you will need spare parts for the Junkers geyser, which can be immediately purchased from the master who will deal with the breakdown. If you have a question about how to clean the Junkers geyser, then you can read this in the instructions, and also contact the gas service.

If during operation, the column produces a low water temperature, then this is most likely due to the low power of the device. It just can't handle hot water. If you still have a low-power column, then we advise you not to immediately and simultaneously open the hot water taps in the toilet and in the kitchen. This will allow you to quickly heat water with a low-power device.

Naturally, the wick can go out in the gas column Junkers. Most likely your column is clogged. Another indication of clogging may be that the flame is yellow. We recommend calling the gas service immediately.

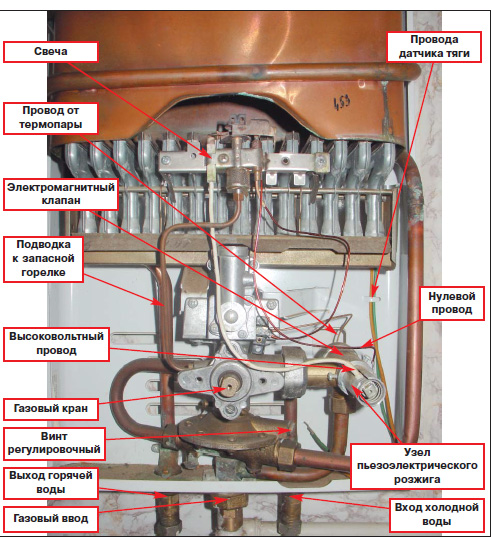

Geyser Junkers - bottom view

Another breakdown of the gas columnJunkersit may be that during operation there is a smell of gas.

This is the most dangerous breakdown, which threatens with serious consequences. In this case, you need to turn off the column, Ventilate the room and call the gasmen. At the end of this article, I would like to tell you that we do not recommend repairing, cleaning, connecting the device ourselves. Such work is cautious and can only be performed by knowledgeable specialists in their field.

This article is about geysers Junkers WR400-1, Junkers WR350-1, Junkers WR250-1 with piezo ignition. This is a line of Junkers geysers, they differ only in power and, accordingly, the size of the heat exchanger, the number of burner sections and the settings of the water unit. The principle of operation and design of these columns is the same. Because video analyzes are made on the basis of the WR400-1, then I will talk about this gas water heater, but everything that I show and tell is applicable to the entire line.

Geyser Junkers WR400-1 is a classic gas column design with piezo ignition. It is in this modification of the geyser that the basic principles are laid down, which other manufacturers will later copy. In a series of video clips, I will tell you as much as possible about this device. Studying the design of the column Junkers WR400-1, you can easily master further modifications of gas water heaters that are produced today under the Bosch brand.

Introductory remarks and general overview of the Junkers WR400-1 geyser:

Water node.

Material: plastic, brass, steel, rubber.

Consists of: body, plate with stem, membrane, water flow regulator (manual and automatic), filter, springs, venturi fitting.

Functions: Controls the inclusion of the geyser, determines the presence of water flow through the geyser, maintains a constant water flow within the specified ranges due to the automatic flow regulator, filters the water entering the geyser, regulates the power of the main burner and the temperature of water heating by acting on the gas valve.

The video clip is devoted to an overview of the Junkers WR400-1 gas column water unit:

Ignition group.

The ignition group is designed to ignite the main burner during gas supply.

Material: silumin, steel, brass.

Consists of: gas supply pipe, nozzle, nozzle, ignition electrode, thermocouple.

The video clip is devoted to an overview of the Junkers WR400-1 gas column ignition group:

Main burner.

The main burner is used to receive, supply, distribute and burn the gas-air mixture. It is very important to keep the main burner clean at all times. Clean the main burner of the geyser at least once a year. It is also necessary to clean the collector nozzles.

Material: Steel, silumin, brass.

Consists of: Burner sections, header, nozzles, union nut.

Vido review is dedicated to the main burner of the gas column Junkers WR400-1:

Gas node.

The gas unit is designed to regulate the gas supply to the main burner. Responsible for blocking the gas supply with a solenoid valve.

Material: silumin, brass, steel

Consisting of: body, adjustment knob, spring system, valves, solenoid valve

The video clip is dedicated to the Junkers WR400-1 geyser gas unit:

Security automation.

To ensure safe operation of the geyser Junkers WR400-1 is equipped with safety automatics.

The security system includes: solenoid valve, thermocouple, overheating sensor, draft sensor.

The video clip is dedicated to a detailed review of Junkers WR400-1 gas column safety automation:

Malfunctions that occur during the ignition of the gas column.

Does the geyser go out when turned on? Do not move the handle to the working position? Ignition wick does not ignite? These are typical malfunctions that occur during the ignition of the geyser. I will try to tell you about what you need to pay attention to when typical malfunctions occur at the Junkers WR400-1 geyser.

The video clip is devoted to a detailed overview of the malfunctions that occur during the ignition of the geyser Junkers WR400-1:

Malfunctions that occur during the operation of the gas column.

The geyser does not heat up, turns off during operation, boils, etc. All these are typical malfunctions that occur during the operation of the geyser. I will tell you about what you need to pay attention to when typical malfunctions occur at the Junkers WR400-1 geyser.

The video clip is devoted to a detailed overview of the malfunctions that occur during the operation of the geyser Junkers WR400-1:

05 Feb 2013, 04:21

Help solve the problem. The Junkers column has recently stopped working normally. It is essentially not possible to turn it on, when you hold the start button - the gas goes on, the flame is there, as soon as you let go - the flame goes out and the gas shuts off. Previously, this was not the case, everything worked normally, I held the button a little, released it - everything functions.

05 Feb 2013, 04:27

There can be many reasons, it depends more on the design of the column itself, already specifically on its type. I did not personally encounter the Junkers, but the problems are usually standard.

This is most likely a thermocouple contact that has oxidized somewhere and does not give the correct signal to the burner control system. If you clean it up, it might work.

Malfunction at the Junkers gas column - the malfunction igniter goes out

05 Feb 2013, 04:28

I think you need to look at the gas valve, it happens that it is buggy, because the thermocouple itself rarely fails, it is almost eternal. It’s better not to do such work yourself, here everyone’s safety is above all. Call the service, I think a person can fix this problem not expensively and quickly, why climb yourself if you have never encountered this.

Malfunction at the Junkers gas column - the malfunction igniter goes out

05 Feb 2013, 04:31

The serviceman may suggest short-circuiting the thermocouple if this is the cause. I would not advise you to agree to this, if you turn it off, the column will work, but this does not guarantee its further safe operation.

If suddenly the gas goes out, then it will still go, even though it comes a little from its wick.

You do not have the required rights to view attachments in this message.

Malfunction at the Junkers gas column - the malfunction igniter goes out

In accordance with the requirements of the regulatory and technical documents in force on the territory of the Russian Federation, maintenance and repair of gas-consuming equipment must be carried out by a specialized organization that has a certificate of admission to this species works, as well as duly certified personnel.

Call a service technician accordingly.

Sergey N wrote: The serviceman can offer to short-circuit the thermocouple if the reason is in it. I would not advise you to agree to this, if you turn it off, the column will work, but this does not guarantee its further safe operation.

A serviceman from an official service will NEVER offer such a thing, since he is responsible for his actions according to the law, which is evidenced by the contract, work order. But "Uncle-Vasya-master-of-all-trades" - easily! Or maybe not offer, but silently do "the right way", but he is not responsible for the consequences!