And includes the following works and topics for study:

- Gas pipeline pressure;

- Gas pipeline materials;

- Connecting gas pipelines in the house;

- Requirements for gas-fired equipment (stove, gas boiler);

- How to install a gas pipeline and gas equipment in the house;

- Delivery and acceptance of the gas pipeline at home.

Let's start with the gas pressure and how to reduce it.

Home gas pipeline pressure

The nominal gas pressure for a domestic gas pipeline must be in the range of up to 2 mPa ÷ 1000 (artificial gas) - up to 3 mP ÷ 1000 (natural gas) - up to 4 mPa ÷ 1000 (liquefied gas). Main gas pipelines can have a pressure of 0.1-0.6 MP. The gas pressure is reduced before it is fed into the internal gas pipeline of the house with the help of the house gas control point (DRP).

The DRP is mounted on the wall of the house in a closet or on a site in a cabinet raised on a fireproof platform, with a separate grounding.

Internal gas pipeline material

For the internal gas pipeline of the house, the following steel pipes are used:

- Seamless pipes;

- Straight welded pipe, with an equally strong seam to the main pipe;

- With a spiral seam;

- All types of water and gas pipes.

How to connect gas pipes

Preferably a swivel joint of pipes for gas. It is possible to connect with flanges and on the thread the connection points of the gas fittings. The threads are sealed with flax, which is coated with red lead paint or whitewash on lead. A more modern sealant is FUM tape (fluoroplastic sealing material).

When laying an internal gas pipeline, you will have to bend it. Bending radii are standard. When installing pipes up to Ø4 cm, the bending radius must be at least 2.5 pipe diameters. For pipes 4-5 cm, bending radius is not less than 3 diameters. Pipes of other diameters in the gas pipeline do not bend.

Flanged connection of gas pipelines

You can see the flanged pipe connection in the photo. Such a connection needs gaskets. They are made of paronite. In the internal gas pipeline of the house, a flange connection is hardly needed, although it is possible in the DRP.

Welding gas pipes

The main connection of gas pipes in the house is welding. Any welding can be used:

class = "eliadunit">

- Electric arc welding by hand (electrodes No. 42, 42A, 46, 46A, 50A).

- Auto welding with fluxes and wire Sv-08-A, Sv-08-GA.

The same wire is used for gas welding. In the internal gas pipeline of the house, you need to use fittings (valves, valves, taps) only designed for work in a gas environment.

Requirements for gas-fired equipment

- Gas stoves with 2-4 burners are installed in the house in accordance with the relevant GOST or TU.

- Gas meters are used to control gas consumption.

- The water heater must be equipped with an automatic device to turn off the burners in case of gas “loss”;

- Air heating devices operating on gas should have similar automation.

Preparation for installation work

Before installing the systems, you need to perform the following preparatory work:

- Make through holes for pipes (walls, floors, foundations) for laying gas pipeline pipes;

- If you plan to hide a gas pipeline, you need to prepare grooves for it;

- The floors where the gas equipment will stand must be ready;

- When installing the equipment on the wall, the walls are plastered;

- Plumbing and equipment to which gas and hot water will be supplied must be in place.

Installation rules

Gas pipes are connected by welding;

- Control, shut-off, regulating devices are connected by thread or flanges. Skewed connections are unacceptable;

- Pipe joints cannot be hidden in a gate or box;

- Connections need direct access;

- Pipes need to be painted;

- When closing pipes with a box, from gas. pipes to the box must be at least 10-11 cm;

- 10-15 cm should separate the weld from the passage through the wall and basement of the house;

- For convenient installation and dismantling, cranes, inlets, branches, you need to install squeegees with locknuts;

- Usually, the distance from the gas pipes to the walls of the house is indicated in the gasification project of the house. If this is not the case, a distance is taken not less than the diameter of the gas pipe.

Gas pipeline laying

Let's look at the permitted minimum distances from the gas pipeline to other communications.

- From the surface of the gas pipe to the open wiring, it should be 25 cm when laying parallel and 10 cm when crossing;

- For hidden wiring, these distances are reduced to 5 cm and 1 cm, respectively. The same rule works for piping;

- Distribution, lead-in shields with gas pipes should not intersect;

- There must be a distance of at least 1000 mm to the "bare" busbars of the electrical wiring;

- Engineering communications (water, sewerage) intersect with the gas pipeline at least 2 cm. Parallel installation is selected locally and is not standardized.

Installation of gas consumers at home

- A gas water heater is installed 2 cm from a fireproof wall and 3 cm from a non-combustible wall. The walls are insulated with a sandwich made of 3 mm asbestos and roofing steel. The insulator should be 100 mm larger than the dimensions of the water heater on each side.

- The tiled wall does not need additional protection.

- The tree is plastered over the mesh. Then they are covered with asbestos or asbestos plywood, and covered with roofing steel.

- The wall where the slab stands is closed from the floor. The distance from the slab to the wall is taken as 70 mm.

Gas boilers

- The gas boiler or boilers are installed in a separate furnace or in the kitchen. The room where the boiler is located must be equipped according to special rules. (Read Installation of a gas boiler in the house).

- The wooden wall and floor where the boiler is located must be protected with asbestos sheet and roofing steel. An internally insulated boiler is not insulated from the walls.

- All gas appliances must be equipped with a chimney. The diameters of the chimneys are taken from the passports for the devices.

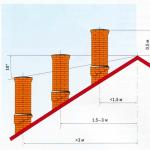

Gas pipe laying on the street

When laying gas pipes along the facade of a house, it is prohibited:

- Welding or joining pipes under windows;

- Lay gas pipes thicker than 50 mm on the wooden façade.

Installation of gas meters

Gas meters are installed in visible places with easy access for service personnel. The meter is mounted strictly horizontally or vertically. The meter should not shake or wobble.

Delivery and acceptance of internal gas supply systems

- Hidden works are accepted during the installation process;

- The finished gas pipeline is tested by the contractors together with the customer and the distribution zone of the Oblgaz branch. The results are recorded in the construction passport or in a separate act.

- The gas pipeline is checked with air under pressure.

Water testing is prohibited.

- Checking for defects of connections is carried out by pressure: 100000 Pa;

- Checking the tightness of connections by pressure: 4000 Pa with a counter and 5000 Pa without a counter.

- The tests are carried out with the devices switched on. The gas pipeline is serviceable for the tightness of the connections if the pressure in the pipes drops by no more than 200 Pa in 5 minutes.

According to the tests, an act is drawn up. The act is signed by the installation organization and the district electric power station. According to this act, the selection committee consisting of: the customer, the installation organization, the distribution zone and the Technical Supervision gives permission to start the gas. Gas is allowed into the house by the district repair and maintenance service, in the presence of the organization that did the installation. Further, the system is accepted into operation according to the act. Acceptance of the gas supply system for operation is formalized by an act.