The need to classify gas pipelines came into our lives with the widespread use of gas technologies for the needs of the population. Heating of residential, administrative, industrial buildings, the use of gas both in cooking and in production has long become a common thing for us.

The classification of gas pipelines is necessary measures and rules for systematization gas pipelines. can differ both in their purpose and in a number of indicators, such as: pressure, material from which it is made, location, volumes of transported gas, and others.

Article content

On the types of classification according to the purpose of the highway

Due to the characteristic specifics of their use, gas pipes can be classified in several directions at once. After that, for a single gas pipeline, a number of characteristics can be compiled that determine its properties and design features.

Special binding plates located along the entire route of the gas pipeline can tell us about this in detail. They are signs-signs measuring 140x200 millimeters, with encrypted information on the gas pipeline.

Distributed in green (for steel versions) and yellow (polyethylene pipes) colors. Signs can be placed on the walls of buildings, as well as on special posts near the tracks. These signs are installed at a distance of no more than 100 meters from each other, observing the line of sight zone.

![]()

When planning gas pipes, one can distinguish: street, intra-quarter, inter-workshop and yard. The characteristic by location does not end there, because the laying and insertion of communications is possible on the ground, underground and above ground.

In the gas supply system, gas pipelines can be classify according to their intended purpose:

- distribution. These are external gas pipelines supplying gas from gas sources to distribution points, as well as medium and high pressure gas pipelines connected to one facility;

- gas pipeline input. This is the section from the connection to the gas distribution pipeline to the inlet device that turns off the system;

- inlet gas pipeline. This is the gap from the disconnecting device to the directly internal gas pipeline;

- inter-settlement. Such communications are laid outside settlements;

- interior. An internal gas pipeline is considered to be a section that starts from the introductory gas pipeline to the final unit using gas.

Classification of gas pipelines by pressure

The pressure in the pipe is the most important indicator of the functioning of the gas pipeline. By calculating this indicator, it is possible to determine the capacity limit of the gas pipeline, its reliability, as well as the degree of risk arising during its operation.

The gas pipeline, undoubtedly, is a potentially dangerous object, and therefore the laying or tie-in of gas pipelines with a pressure exceeding the permissible one carries great risks for the gas transmission system and the safety of people around. Proper classification rules will help avoid accidents at an explosive site.

Separate high, medium and low pressure gas pipelines. A more detailed classification of gas pipelines is given below:

- high pressure category I-a. The gas pressure in such a gas pipeline may exceed 1.2 MPa. This type is used to connect steam and turbine plants, as well as thermal power plants, to the gas system. Pipe diameter from 1000 to 1200 mm;

- high pressure category I. The indicator ranges from 0.6 to 1.2 MPa. They are used to transfer gas to gas distribution points. The pipe diameter is the same as the category I-a diameter;

- high pressure category II. The indicator is from 0.3 to 0.6 MPa. It is supplied to gas distribution points for residential buildings and industrial facilities. The diameter of the high pressure line is from 500 to 1000 mm.;

- medium pressure category III. The indicator can be in the range from 5 kPa to 0.3 MPa. They are used to supply gas to gas distribution points through medium pressure pipes located on residential buildings. Medium pressure pipe diameter from 300 to 500 mm;

- low pressure category IV. Permissible pressure not exceeding 5 kPa. Such gas pipes supply the carrier directly to residential buildings. Low pressure gas pipelines have a pipe diameter of not more than 300 mm.

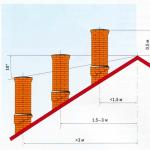

Types of gas pipelines by depth

Taking into account the factor of urban conditions, the load from heavy transport, the effect of snow and rain on the ground, the depth of the laying of communications in the city and their main variations requires consideration of them separately.

The rules for laying gas pipelines also depend on the type of gas transported. Pipes supplying dried gas can be laid in the freezing zone of the soil. The depth of laying is determined primarily by the probability of mechanical damage to the soil or pavement.

Dynamic loads must not cause stress in the pipes. At the same time, an increase in the depth of laying directly proportionally affects the cost of road repair and construction work required when laying pipes.

![]()

- on driveways of streets with concrete or asphalt pavement, the minimum laying depth is allowed at least 0.8 meters, in the absence of such a pavement - laying with a depth of 0.9 meters;

- the minimum depth of laying pipes transporting dry gas is assumed to be 1.2 meters from the surface of the earth;

- on the streets and intra-quarter territories, where there is guaranteed to be no traffic and there will be no traffic, the laying rules allow that the laying depth will decrease to 0.6 meters;

- the depth of the underground gas pipeline depends on the presence of water vapor and the level of soil freezing. When transporting dry gas, the laying depth is usually 0.8 meters.

Laying a gas pipeline in a trench.mp4 (video)

Main gas pipelines and their protected zones

Main gas pipelines are whole complexes of technical structures, the main task of which is to transport gas from the place of its production to distribution points, and then to the consumer. In the immediate vicinity of the city, they turn into local ones. The latter, in turn, serve to distribute gas throughout the city and deliver it to industrial enterprises.

The design and laying of main communications should take into account the volume of gas, the power of the equipment working with it, gas pressure and, of course, the rules for laying main gas pipelines. The location of the main gas pipeline near the facility that needs to be gasified does not mean at all that the tie-in will be applied specifically to it.

The tie-in can be laid several kilometers from the gasified area. In addition, the tie-in must take into account the practical possibility of providing the consumer with a given power and pressure in the pipe.

Main pipes have different performance. It is affected, first of all, by the fuel and energy balance of the area where the pipeline is planned to be laid. At the same time, it is necessary to rationally determine the annual amount of gas, taking into account the volume of the resource, for the future after the start of operation of the complex.

Typically, the performance parameter characterizes the amount of gas supplied per year. During the year, this indicator will fluctuate downward, due to the uneven use of gas by the population by season. In addition, it is also affected by changes in the temperature of the external environment.

The security zone of the main gas pipeline implies a section on both sides of the gas pipeline, limited by two parallel lines. Security zones for main gas pipes are required due to the explosive nature of such communications. And therefore it should be carried out taking into account the required distance.

To comply with the required length of security zones, the following rules must be taken into account:

- for high pressure lines I category - the security zone is 10 m;

- for high pressure pipes II category - the security zone is 7 m;

- for medium pressure lines — the security zone is 4 m;

- for low pressure pipes - the security zone is 2 m.