The arrangement of a gas pipeline to provide a private dwelling or site is considered a difficult technical task due to the explosive hazard of domestic gas. Carrying out the gasification of the premises, one should be very careful with each stage of this work, since any mistake is fraught with very serious consequences.

Most often, gas pipelines for honest houses and apartments are equipped with metal products. Steel pipes for gas supply are characterized by their ability to withstand internal pressure perfectly. Such a pipeline is completely sealed, which reduces the risk of gas leakage to zero. The selection of pipes is carried out taking into account the working pressure in the gas line.

Conditions in gas pipelines can be as follows:

- With low pressure - up to 0.05 kgf / cm2.

- With medium pressure - from 0.05 to 3.0 kgf / cm2.

- With high pressure - from 3 to 6 kgf / cm2.

What pipes are used for the gas pipeline? The use of thin-walled metal pipes is only permitted on low-pressure gas pipelines. This material has an exceptionally light weight, which makes it possible to equip systems with a complex configuration from it. Also, thin-walled metal pipes are distinguished by good flexibility: if necessary, to give such a product a small angle, you can do without a pipe bender, doing everything by hand.

If necessary, such a pipe for a gas pipeline is easily soldered. In addition, special connecting fittings can be used for steel threaded pipes. Only sealing hemp fiber is used to connect socket thin-walled elements.

Features of using different types of gas pipes

High-pressure gas pipelines are equipped exclusively with massive pipes. If the line has increased strength requirements, it will be necessary to use steel pipes without seams. You should be prepared for the fact that welding such elements is a much more complicated procedure than soldering thin-walled pipes. From the point of view of optimal performance, copper pipes are especially distinguished: in many respects they are preferable to thick-walled steel products. In terms of reliability, both of these varieties are almost the same, but copper weighs much less. From the mass use of copper tubes in everyday life, their high cost keeps them.

When using thin-walled pipes, one should take into account their high thermal conductivity, which is why condensation often occurs on their surface. To protect against corrosion, it is recommended to cover the finished gas pipeline system with several layers of oil paint. Underground gas pipelines are organized using plastic pipes, which are characterized by flexibility, elasticity and low cost. Most often, these are products made of polypropylene or polyethylene, which perfectly tolerate underground conditions during the gasification of private properties. If it is required to equip the cottage with a low-pressure gas pipeline, black polyethylene pipes with the corresponding yellow marking are used. It is not practiced to use polyethylene pipes under high pressure as a gas pipeline.

Gas distribution inside the premises is carried out with vulcanized rubber hoses, which have textile reinforcement. They are not suitable for high pressure: they are usually used to connect gas stoves to cylinders or geysers.

The use of flexible hoses has the following limitations:

- If the air temperature in the area exceeds +45 degrees.

- If seismic activity of more than 6 points is possible on the territory.

- At high pressure inside the gas pipeline system.

- If it is required to equip any room, tunnel or collector with a gas pipeline.

All of these situations are prohibited for using HDPE pipes as a gas pipeline. It will be safer to stop at a thin-walled or seamless type steel gas pipe.

Regulations for gas pipelines in apartments

To achieve safety and comfort when using a gas pipeline, the following standards must be observed during its installation and operation:

- Residential premises cannot be a place for laying gas pipes. The same applies to air ducts and ventilation shafts.

- Mount a thin-walled metal pipe should be so that it does not block the window or doorway.

- Laying gas pipes in hard-to-reach places is prohibited. First of all, we mean various decorative wall claddings, unless they can be quickly dismantled. Any section of the gas pipeline must be provided with quick access in case of emergency.

- The distance between the gas pipe and the floor surface is at least 200 cm.

- If flexible sections of the gas pipeline from a thin-walled pipe are used, then their length cannot be more than 300 cm. The connection of individual fragments of the system must be done with high quality.

- It is possible to install gas communications only in those rooms where the ceiling is not lower than 220 cm. Good ventilation must be ensured.

- When laying gas pipes in the kitchen, its ventilation system cannot be adjacent to the rest of the living rooms.

- When finishing the ceiling and walls near the gas communication, it is required to use non-combustible plaster. If plaster is not used in the room, then metal sheets with a thickness of at least 3 mm can be used to insulate the walls.

Ventilation and security

When installing a geyser, an exhaust pipe must be used (read: ""). A flexible corrugated aluminum pipe for these purposes is prohibited. Exhaust pipes for the column can only be steel or galvanized. A geyser, like any other heating device, is recommended to be equipped with fuses: they will cut off the gas supply in case of flame outage.

Features of arranging a gas pipeline in the kitchen from thin-walled metal pipes:

- Work begins with shutting off the gas supply valve.

- If the gas pipe in the kitchen needs to be relocated, the gas pipeline should be pre-purged to remove any remaining gas from the system.

- The gas pipe on the wall must be very well fixed. To do this, the product package includes clamps and brackets: they are used taking into account the diameter and length of the pipeline.

- When passing an electric cable near the gas pipeline, a distance of 25 cm should be observed between them. The gas system and the electrical switchboard should be 50 cm apart from each other.

- The gas-piped kitchen system should not be adjacent to cooling appliances such as a refrigerator or freezer. If you close the gas pipes with a refrigerator, its radiator will most likely overheat.

- When installing thin-walled gas pipes, heaters and a gas stove should be removed.

- It is forbidden to lay gas pipes in the kitchen on the floor surface, under the sink, near the dishwasher.

- When carrying out repair work, it is advisable not to use sources of artificial light. The room must be constantly ventilated.

Standards for gasification of a private house

Before starting work, you should notify the local gas service about what is happening. The responsibility of this organization is to provide technical conditions for determining the procedure for gasification. When the technical coordination is completed, an individual project is being developed for the upcoming work. Permission to lay gas communication should also be obtained from representatives of the automobile inspectorate.

If some houses in the area are already gasified, then you only need to connect the gas pipe to the main line. In this case, the gas service is obliged to notify the working pressure parameters in the main pipeline. This will make it possible to choose the right pipes for arranging your site. The gas supply system can be autonomous or central: it depends on which source this area will be supplied from. Private houses can be equipped with aboveground and underground gas pipelines. Mounting and installing gas pipes on the site is not very difficult - usually it is done much faster than obtaining the appropriate permits.

When laying a gas pipeline, the following sequence should be observed:

- Lay the pipeline from the distributor to the dwelling. If necessary, a tie-in is made into the main gas pipeline (more details: "").

- To enter the pipe into the house, a cabinet with a pressure reducing reducer is used.

- Next, you need to organize the distribution of pipes in the premises (kitchen, boiler room). For this, a pipe for a low pressure gas pipeline is used.

- Carry out commissioning procedures, equipment handover and acceptance, check the gas stove and column for operability. Most often, this requires the presence of a gas service inspector.

The structure of the gas pipeline in a private house consists of the same points as a similar system in an apartment.

Sequence and installation rules

Installation work should be carried out according to the following rules:

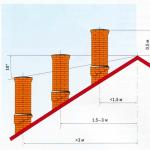

- When laying underground gas pipes, the optimal depth is 1.25 - 2 m.

- At the site where the pipe enters the house, the depth should be reduced to 0.75 - 1.25 m.

- Liquefied gas can be transported at a depth below the freezing depth of the soil.

- When installing a gas boiler, it should be noted that one piece of equipment must have a room area of 7.5 m2.

- For the installation of boilers and columns with a power of less than 60 kW, rooms of at least 2.4 m will be required.

An autonomous source of gas in the backyard is carried out in accordance with specific safety standards. This will guarantee the normal functioning of the stove, column and boiler. An underground tank should be located no closer than 15 m from the well, 7 m from outbuildings, and 10 m from the house. The most popular types of such tanks are tanks with a volume of 2.7 - 6.4 m3.

Rules for laying underground gas pipelines:

- What pipes are used for the gas pipeline in this case? With a positive result of the study of soil for corrosion, it is better to refrain from laying underground communications. The exception is situations when high-voltage lines pass nearby: in this case, the pipes are laid underground using additional insulation.

- If a polyethylene pipeline is laid, high-strength products (PE-80, PE-100) are used for this. PE-80 pipes are able to withstand operating pressures up to 0.6 MPa: if this figure is higher, it is better to use PE-100 products or steel pipes for a high-pressure gas pipeline. The depth of penetration into the ground is at least one meter.

- Communications with a working pressure above 0.6 MPa are allowed to be equipped with reinforced polyethylene pipes. The requirements for the depth of the bookmark here are also from one meter.

- In areas where arable work or abundant irrigation will be carried out, the depth of laying the gas pipeline is increased to 1.2 m.

If you adhere to all the above requirements and rules, the arrangement of an underground gas pipeline can be done with your own hands.