Gasification of the private sector is now the norm, although some ten years ago, many could only dream of it. However, the use of gas by a wide range of consumers causes a number of problems that should be known in advance. This knowledge will be useful to you when choosing a home or buying expensive gas boilers and other equipment that consumes blue fuel.

1 Gas veins - how does gas circulate through the system?

Before the gas ignites with a blue flame on your stove, it travels hundreds and thousands of kilometers through gas pipelines. The most important artery of the gas transmission system is the gas pipeline. The pressure in such lines is very high - 11.8 MPa, and is completely unsuitable for private consumption.

However, already in gas distribution stations (GDS), the pressure drops to 1.2 MPa. In addition, additional gas purification takes place at the stations, it is given a specific smell, which is perceptible by the human sense of smell. Without odorization, as this process is called, we would not sense the presence of gas in the air when it leaks, since methane itself has neither color nor smell. Ethanthiol is often used to give a smell - even if there is one part of this substance in several tens of millions of parts of air in the air, we will feel its presence.

From gas distribution stations, the gas path runs to gas control points (GRP). These points are actually the point of distribution of blue fuel between consumers. At hydraulic fracturing, automatic equipment monitors the pressure and recognizes the need to increase or decrease it. Also, at the gas control points, another stage of gas filtration takes place, and special devices register the degree of its pollution before and after cleaning.

2 Low or medium - which pressure is better?

Previously, most residential buildings were supplied with a low pressure gas pipeline (0.003 MPa), since a medium pressure pipeline (0.3 MPa) requires more extensive installation work and the purchase of special equipment that reduces the pressure directly at the gas inlet to the pipes inside the house.

However, with an increase in the number of consumers in the low-pressure gas pipeline, there may simply not be enough fuel for everyone - this becomes especially noticeable in winter, when most people turn on gas boilers at full capacity. In a medium pressure system, this problem is practically eliminated. The high requirements of modern ones should also be taken into account. With insufficient pressure, many units, at best, produce less power than the manufacturer indicated, and in the worst case, they turn off until the desired pressure appears in the system.

Buying expensive boilers for low-pressure consumers is like throwing money away, since such a purchase will not justify itself at all. It is up to the consumers themselves to solve the problem of gas interruptions. Alternatively, you can purchase a combined one that can be loaded with solid fuel during the absence or too low gas pressure. In the kitchen, you can use a liquefied gas cylinder by installing one burner for this type of fuel.

With increased pressure, the situation is no better - if switchgears are not installed in the houses, the risk of emergency situations increases. Since low pressure gas is considered safer, its use is prescribed in public institutions such as schools, kindergartens, hospitals, as well as factories and enterprises of various types where gas is used for heating purposes. Also, gas pipelines with low rates are laid in small settlements.

In large cities with a high social status, a high-pressure gas pipeline is being laid. The decision on this is made based not only on the number of consumers, but also on their financial ability to pay for the purchase of more expensive and powerful equipment. By and large, consumers do not choose which gas pipeline to use, except perhaps when choosing a place of residence.

3 The difference between gas pipelines by type of laying

The gas pipeline can be laid in different ways. Most often today they use the ring method of laying and dead-end. In the case of a dead-end network, gas enters the user from only one side, while in a ring main, gas enters from two sides and moves further like a closed ring.

There is a big drawback in the dead-end system - when gas services carry out repair or maintenance work, they are forced to disconnect a huge number of consumers from gas. If you live in such a zone, then when choosing a gas boiler, you should take into account the automatic shutdown of the equipment in the absence of pressure, otherwise the unit will run idle.

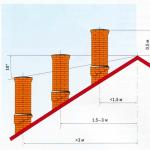

There is no such drawback in the ring system - gas flows from two sides. Due to this, the pressure is evenly distributed among all consumers, while in a dead-end system, the farther the house is from the hydraulic fracturing, the less pressure will be in the pipe. Again, this factor should be taken into account when buying a house - the farther the house is from the gas control point, the more the quality of gas supply is leveled.

4 Reasons for shutting down gas - repair or maintenance?

Breakdowns in the gas supply system are a rather rare phenomenon. Most often, gas is turned off for the reason that some of the consumers needed the services of a gas service to replace or reinstall gas equipment. Only a specialist can carry out such procedures, and it is desirable that this be a master with extensive experience in such work. The gas pipe is de-energized if it is necessary to cut it.

In the private sector, this is much easier to do than in a multi-storey building. If a private owner can simply turn off the tap, then a resident of a high-rise building must first obtain special permission from the appropriate authority.

You should consult with specialists and, if necessary, install or change one or another device that will be connected to the gas main. As noted above, different equipment is designed for different states of the gas itself in the network. It is precisely because of the ignorance of consumers that they have to subsequently redo entire projects. Therefore, always select equipment first, and only then proceed with the drafting of the project. In no case should the gas pressure in the system be neglected, otherwise it can turn into very deplorable situations.