Exposed pipes in the toilet are not only unsightly, but also additional problems associated with cleaning. Cleaning pipelines takes a lot of time and needs to be done regularly.

You can simplify your life by hiding pipes under drywall or plastic panels.

4 ways to hide pipes in a toilet

Before starting work, it is necessary to determine the method of masking based on the size of the toilet and the location of the pipelines.

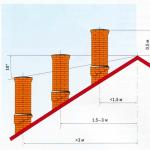

- In a cramped room with pipes located along one wall, you can hide the pipes behind. It reduces the size of the room by an average of 40 centimeters, so it is necessary to install drywall at an acute angle to two load-bearing walls.

- Riser and pipes located in the corner are easier close behind a box. It is mounted from plasterboard or PVC. If the pipes are placed in two corners or diverge at the bottom, the box can be made multi-level. This method is more labor intensive.

- A large toilet will allow build a complete closet, which will mask the pipelines and serve as a storage place for household chemicals and cosmetics. Such a cabinet is quite simple. A frame made of wooden bars is mounted on the wall, then cabinet parts made of chipboard and sheathed with a moisture-resistant material (for example, plastic) are attached to it.

- The fastest way to disguise installation of roller shutters. You will only have to mount a small box near the ceiling, where the blinds will be installed.

The fastest way to disguise is to install roller shutters. You will only have to mount a small box near the ceiling, where the blinds will be installed.

Materials that will be needed to close the pipes in the toilet in a box

A false wall and a box are the most common way to mask pipelines in a cramped apartment.

For work you will need:

- a sheet of wall plasterboard or PVC (as an option, a sandwich panel);

- profile and dowels to them (an average of three for each rack and guide);

- self-tapping screws for metal;

- putty and finishing materials (it can be tiles, wallpaper, paint or emulsion).

To determine the material for sheathing, it is necessary to take into account the humidity in the room, financial capabilities and skills in construction.

On a note. You can use a sandwich panel coated with a polymer or already sheathed with plasterboard. This will reduce the time of work, since no self-plating of the frame is required.

Of the tools you will need: a tape measure, a level, a drill, a screwdriver, a knife for cutting drywall, sandpaper for cleaning cuts, a spatula and, if necessary, a brush for finishing work.

To decide on the material for sewing, it is necessary to take into account the humidity in the room, financial capabilities and skills in construction.

When installing drywall, it must not be allowed to touch the pipelines. Condensation falling on drywall will significantly reduce the life of the box.

- Drywall can absorb moisture, and this is fraught with the appearance of fungus or mold. However, it is easier for them to sew up and it costs less. The price of a standard sheet is 215 rubles (Knauf) (you can read more about the dimensions of the GKL sheets and the calculation rules).

- Cover with plastic (PVC) harder, but it is moisture resistant and durable. In addition, PVC does not require finishing work - the panel can be of any color. The price is correspondingly higher. But do not forget that by purchasing PVC, you can save on wallpaper or tiles. The price of packing panels for ten sheets is from 700 rubles (size 1 by 6 meters, thickness centimeter).

- Sandwichh-panel, in addition to moisture resistance, it also has such an important quality as the ability to retain heat. After all, its base is made of insulation (expanded polystyrene, polyurethane foam or mineral wool). The cost is comparable to plastic panels - from 800 rubles per square meter (one centimeter thick).

![]()

The installation of the box always starts from the bottom of the wall. The profile (bottom guide) is cut to size and fixed to the floor with dowels

Getting Started

- Do-it-yourself frame installation for the box always starts from the bottom of the wall. The profile (lower guide) is cut to size and attached to the floor with dowels (what types of profile are there and which one to use for what we told).

- Vertical side profiles (bearing) are set according to the level, focusing on the horizontal profile already attached at the bottom. And also fixed with dowels.

- If the box is solid, another vertical profile is installed in the center. It will be convenient to attach drywall or PVC to it (the width of the latter is only one meter).

- To the finished frame (more details about the installation of the frame from the profile are described in), drywall (or plastic) of the desired size is mounted using self-tapping screws. The pitch between the screws is twenty centimeters.

- On a finished drywall box you can tile any color and texture - it looks beautiful, lasts a long time and is easy to use (easy to wash and clean from dust). The average price per square meter is from 98 to 1200 rubles. Additionally, special glue is required (average price 980 rubles per 15 kilograms, consumption per square meter 2.5 kg).

Scheme of laying tiles on a frame in which pipes are hidden

- Cheaper option - and painting. The main disadvantage of this finish is the need for cosmetic repairs. The cost of enamel is on average 170 rubles per kilogram, emulsions - 250 rubles per bucket of 14 kilograms. A primer is also required under the paint. Its average price is 320 rubles per bucket of 10 liters.

- Often boxes wallpapered. This finish is the fastest in execution. The disadvantage is the fragility. And paper wallpapers also absorb moisture. Vinyl wallpaper is more reliable (the average price per roll is 0.53 centimeters wide and 10 meters long - 350 rubles). Additionally, you will need wallpaper glue (190 rubles per liter).

- If the sheathing was made of PVC, additional finishing is not required. Consequently, the box will cost exactly as much as paid for the plastic and profile for the frame.

Installing the box will cost an average of 1300 rubles (with a conditional wall height of 2.5 and a width of 1.5 meters).

You can do the work yourself in one or two days (it all depends on the drying of the putty, primer and paint).

The work of the master costs from 125 rubles per square meter. That is, for a wall of an estimated size of 2.5 by 1.5 meters, you need to pay 416 rubles. The master will install the box in about one day (without priming and painting).